Hot air protection device for wet-type electrostatic precipitator

A wet electrostatic precipitator and protection device technology, applied in the direction of external electrostatic separator, electrostatic separation, etc., can solve the problems of high power consumption of electric heaters, pollution of heat preservation barrels, large selection of fans, etc., to ensure stable operation, reduce Power consumption, avoid the effect of flue gas back-channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

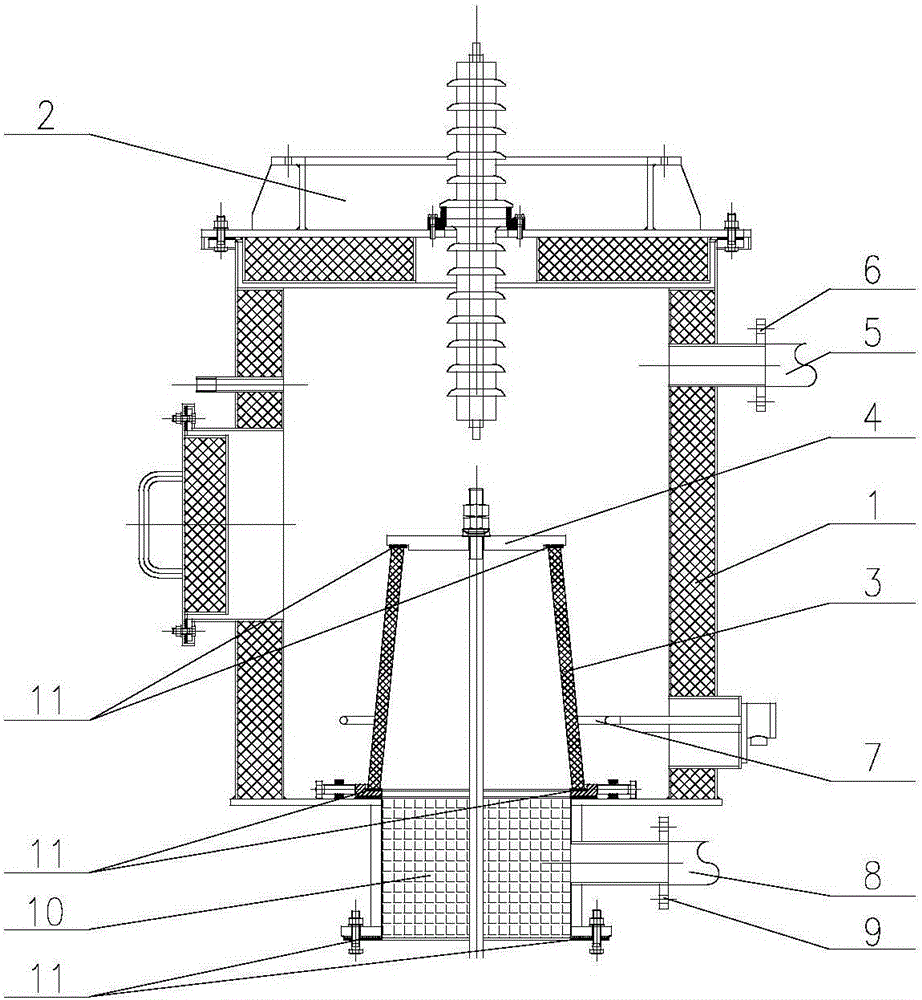

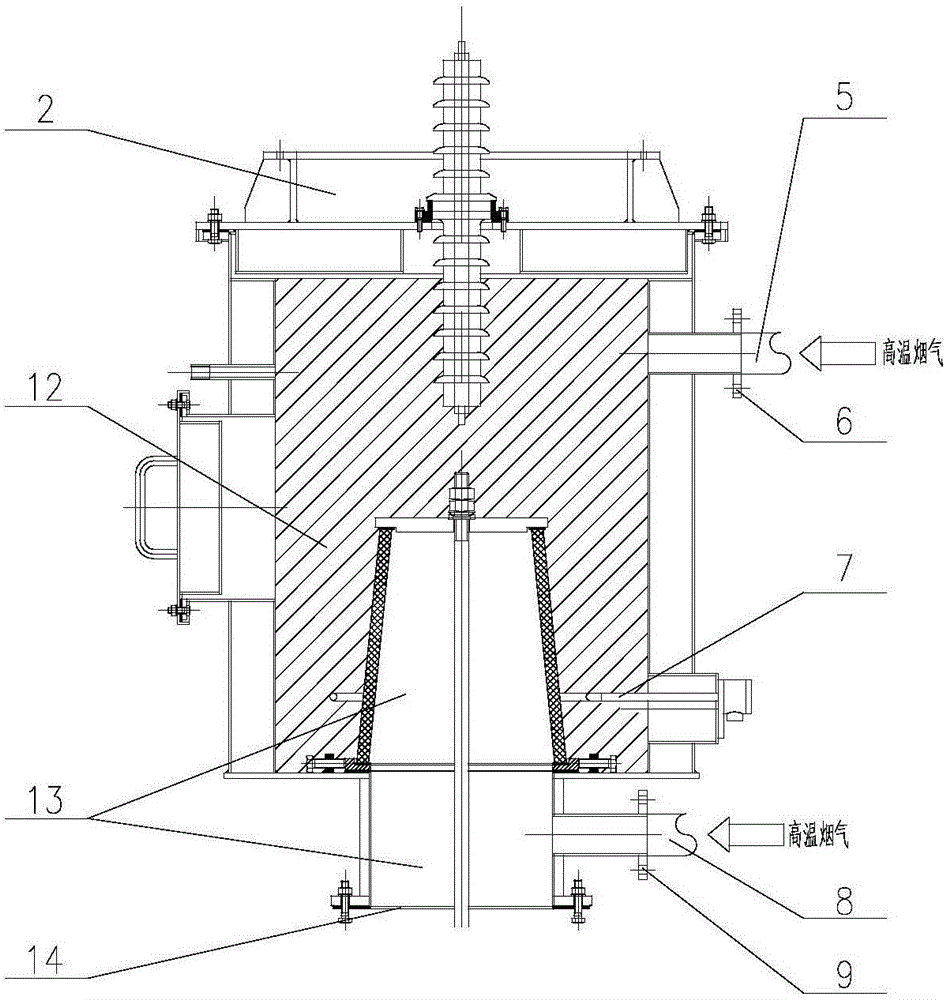

[0019] Embodiment 1 of the present invention: as figure 1 with figure 2 As shown, a hot air protection device suitable for a wet dust collector of a 300MMW thermal power generating unit includes a heat preservation barrel body 1, a heat preservation barrel top cover 2, an insulator body 3, an insulator cover plate 4, an outer protection system and an inner protection system 7. A seal 11 is installed between the insulator body 3 and the insulator cover 4 for sealing. The external protection system is arranged outside the heat preservation barrel body 1, and the heat preservation barrel body 1 lower part is also arranged with a heat preservation barrel connection block 10, and the inner diameter of the heat preservation barrel connection block 10 is 430 mm. The inner wall of the insulation barrel body 1, the top cover 2 of the insulation barrel and the outer wall of the insulator body 3 form an inner chamber 12 of the insulation barrel, and the inner diameter of the inner cham...

Embodiment 2

[0021] Embodiment 2: as figure 1 with figure 2 As shown, this kind of hot air protection device for wet electrostatic precipitator includes heat preservation barrel body 1, heat preservation barrel top cover 2, insulator body 3, insulator cover plate 4, outer protection system and inner protection system 7. The external protection system is arranged outside the insulation bucket body 1, and the insulation bucket connection block 10 is arranged at the lower part of the insulation bucket body 1. The inner wall of the insulation bucket body 1 , the top cover 2 of the insulation bucket and the outer wall of the insulator body 3 form the inner chamber 12 of the insulation bucket. The inner wall of the insulator body 3 , the insulator cover plate 4 and the inner wall of the insulating barrel connecting block 10 form an insulating barrel connecting chamber 13 . The heat preservation barrel body 1 is provided with an inner room hot air duct 5, and the inner room hot air duct 5 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com