Biomass feeding device

A feeding device and biomass technology, applied in the direction of educts, granular/powdered fuel gasification, reagents, etc., can solve problems such as inability to realize pressurized operation, dangerous gas leakage safety accidents, etc., to prevent clogging and high temperature Measures, the effect of preventing hot gas from flowing back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

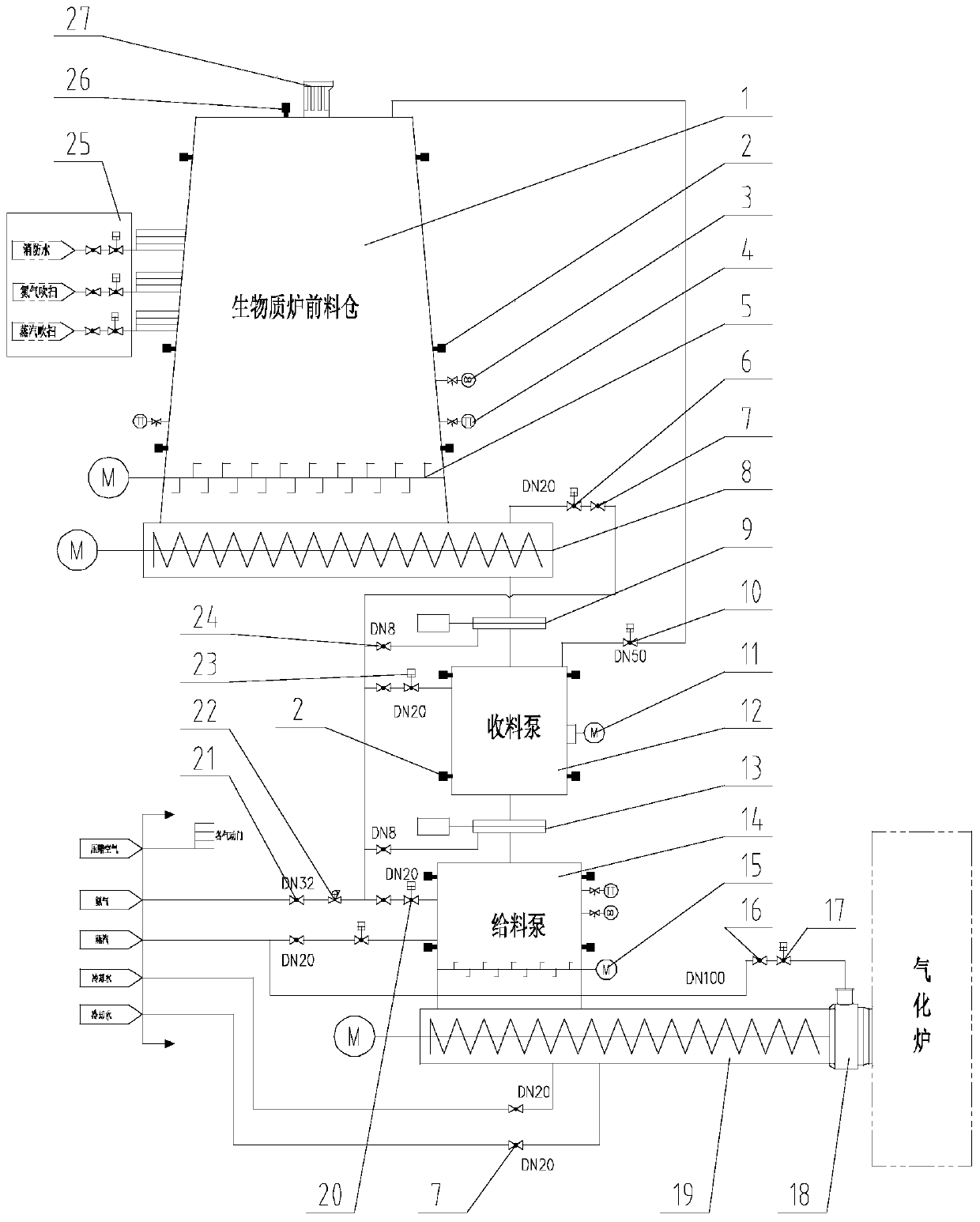

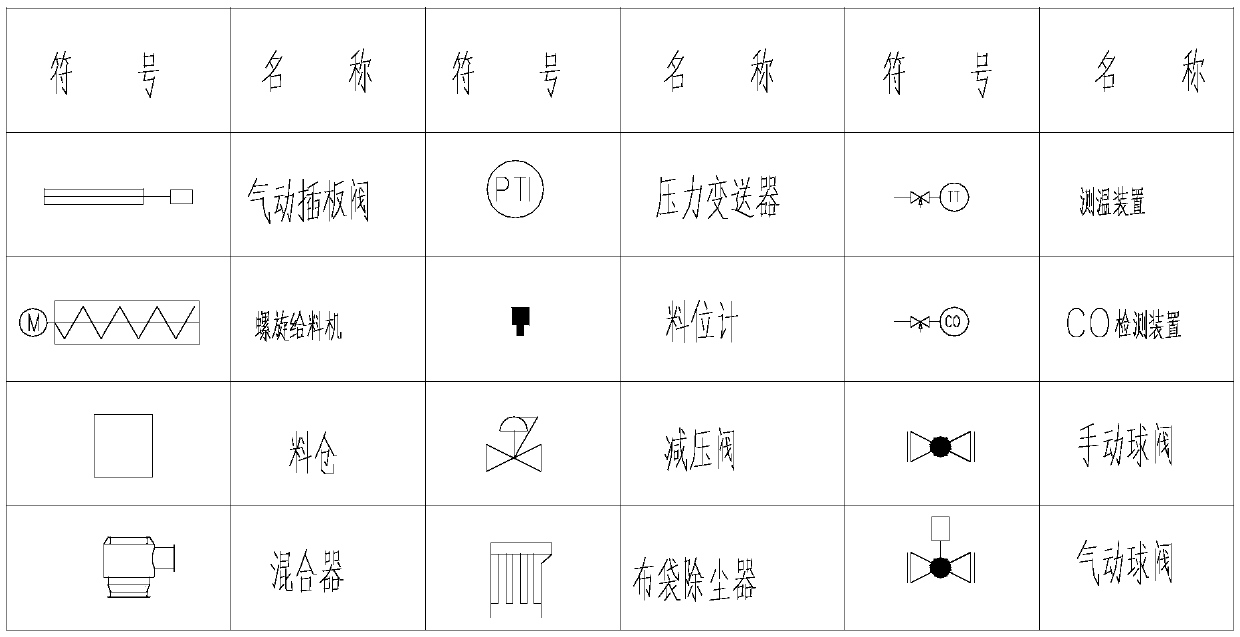

[0018] now attached figure 1 To further explain the invention, the biomass feeding device of the present invention is mainly used for feeding boilers at atmospheric pressure, and cannot satisfy the transportation of biomass materials under pressure conditions. The technical scheme adopted in the invention solves the problem of safely and stably transporting biomass materials to the boiler under the condition of positive pressure.

[0019] Such as figure 1 As shown, the biomass feeding device includes: biomass furnace feed bin 1 (1 seat), material level gauge 2 (14 sets), carbon monoxide detection device 3 (2 sets), temperature detection device 4 (3 sets), material Warehouse shifting device 5 (2 sets), double-screw pneumatic purge valve 6 (1 set), first manual maintenance valve 7 (6 sets), first double-screw feeder 8 (1 set), receiving pump Feed valve 9 (1 set), pneumatic balance valve 10 (1 set), rapping device 11 (2 sets), receiving pump 12 (1 set), receiving pump discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com