Annular sleeve type gas sealing device for feeding system of positive-pressure biomass gasifier and gas sealing method thereof

A feeding system and gasifier technology, applied in the direction of gasification device feeding tools, gasification process, granular/powdered fuel gasification, etc., can solve problems such as poor flow and leakage of feeding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

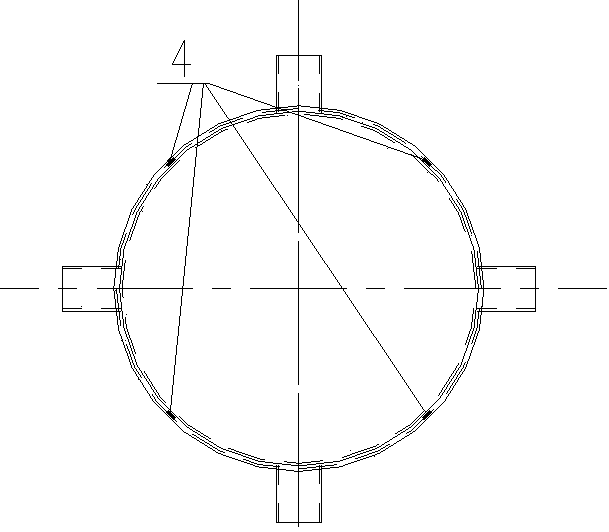

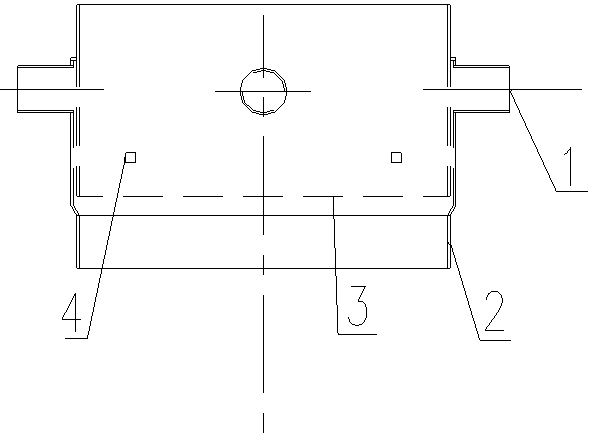

[0012] A ring-type air seal device for the feeding system of a positive pressure biomass gasifier, which consists of: a feeding pipe 3, characterized in that: the mouth of the feeding pipe is covered with a feeding sleeve 2. There is a set of pads 4 between the feed pipe and the feed sleeve to form a gap. The feed sleeve has a set of inert gas inlet pipes 1, and the inert gas inlet The tube and the nozzle of the feed pipe communicate through the gap. The gas outlet of the feeding casing is set outside the mouth of the feeding pipe, and the inert gas inlet pipe is perpendicular to the feeding pipe.

Embodiment 2

[0014] The above-mentioned gas sealing method for the ring-type gas sealing device of the positive pressure biomass gasification furnace feeding system introduces a certain speed of inert gas into the positive pressure biomass gasification furnace feeding system through the inert gas inlet pipe to avoid The toxic and flammable flue gas in the positive pressure gasifier enters the feeding system and ensures the smooth feeding. The inert gas is fed into the gap between the inner feeding pipe and the casing through the surrounding inert gas inlet pipes, and the inert gas is used The pressure head and flow rate of the feed pipe are air-sealed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com