High-temperature and ultrahigh-pressure reheat steam boiler of biomass direct combination energy-conservation circulating fluidized bed

A circulating fluidized bed, reheated steam technology, applied in fluidized bed boilers, steam boilers, fluidized bed combustion equipment, etc., can solve the problems of yellow straw biomass difficulty, short continuous operation time, and low boiler unit efficiency. , to achieve clean and efficient combustion of steam-water cycle temperature control, solve energy waste and environmental pollution, easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

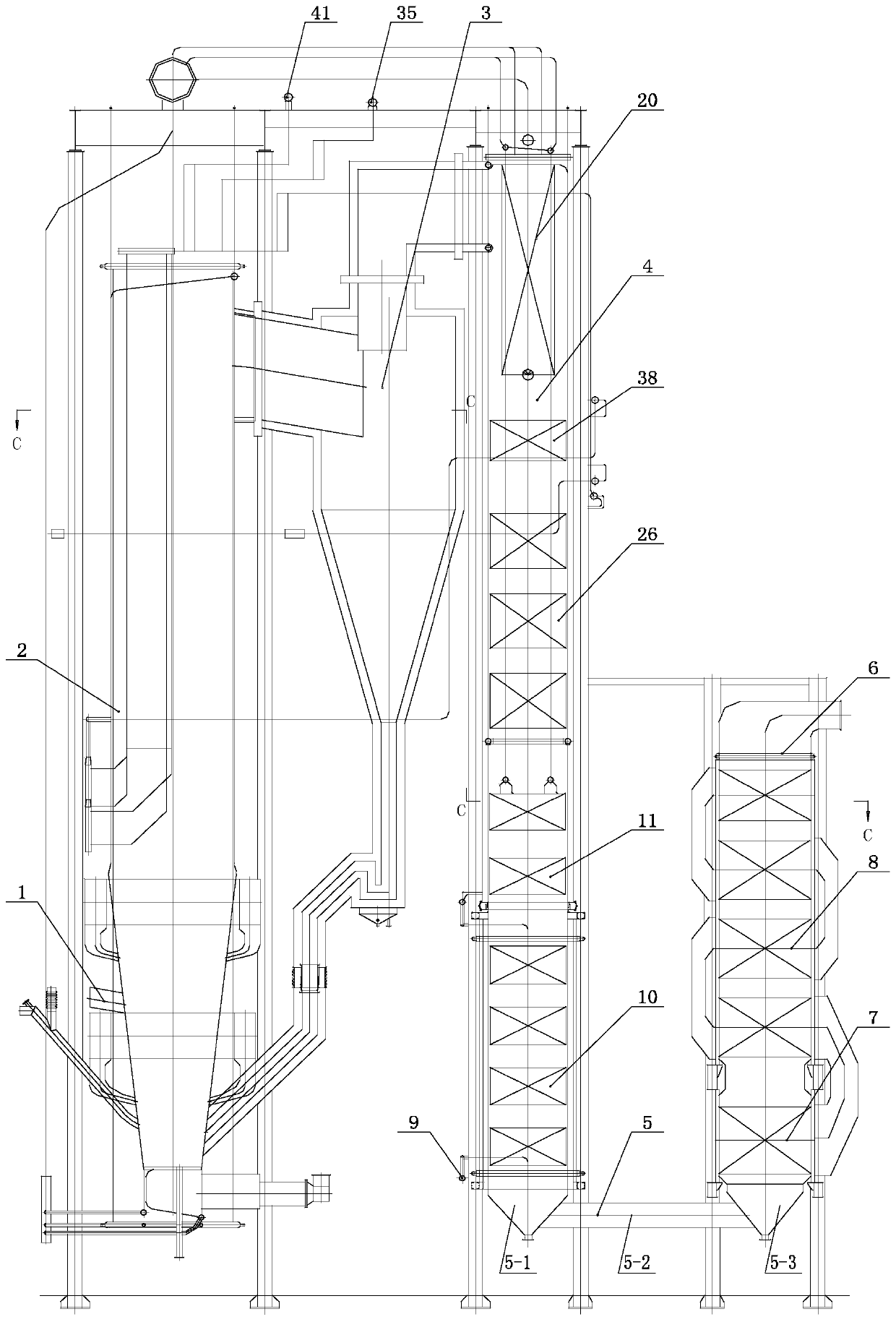

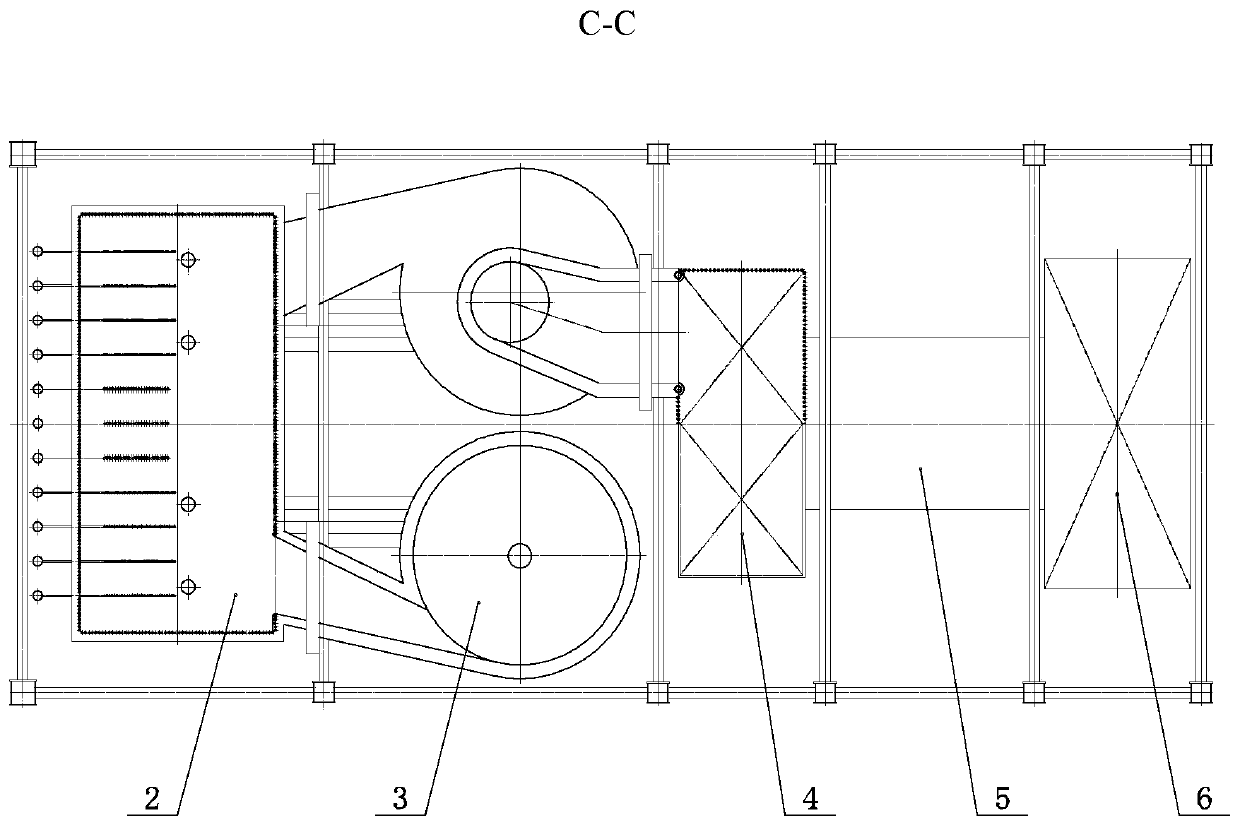

[0020] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, a biomass direct combustion energy-saving circulating fluidized bed high temperature ultra-high pressure reheat steam boiler described in this embodiment, it includes a furnace 2, a first tail flue 4, a connecting flue 5 and a second tail The flue 6, this embodiment also includes a biomass direct combustion system 1 and a separation and return system 3, the biomass direct combustion system 1 is installed at the lower part of the furnace 2, the upper part of the furnace 2 is connected with the upper part of the separation and return system 3, and the furnace The lower part of 2 is connected to the lower part of the separation and return system 3, the smoke inlet of the first tail flue 4 is connected to the upper part of the separation and return system 3, and the lower part of the first tail flue 4 is connected to the second tail by connecting the flue 5 The lower part of the flue 6...

specific Embodiment approach 2

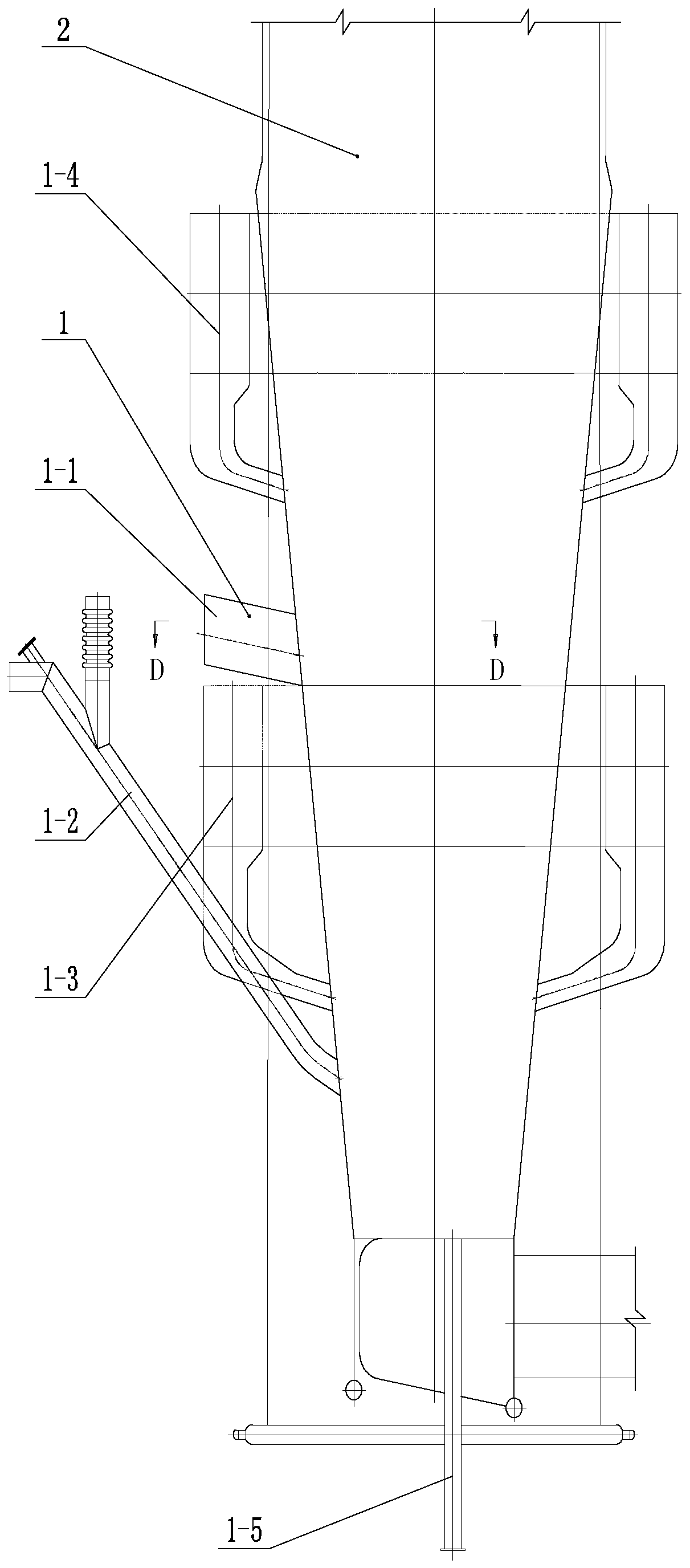

[0022] Specific implementation mode two: combination Figure 1 to Figure 7 Describe this embodiment, the biomass direct combustion system 1 of a biomass direct combustion energy-saving circulating fluidized bed high-temperature and ultra-high pressure reheating steam boiler in this embodiment includes a biomass direct combustion feeding device 1-1, a feeder Device 1-2, secondary air device 1-3, tertiary air device 1-4 and slag discharge device 1-5, tertiary air device 1-4, biomass direct combustion feeding device 1-1, secondary air device 1 -3. The charging device 1-2 is installed in the lower part of the furnace 2 sequentially from top to bottom.

[0023] The biomass enters the lower part of the furnace 2 through the biomass direct combustion feeding device 1-1 for combustion, and the bed material enters the lower part of the furnace 2 through the feeding device 1-2 for internal fluidization. The biomass direct combustion feeding device 1-1 and the feeding The device 1-2 is ...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 1 to Figure 7 Describe this embodiment, the separation and return system 3 of a biomass direct combustion energy-saving circulating fluidized bed high-temperature and ultra-high pressure reheating steam boiler in this embodiment is composed of a separator 3-1 and a return device 3-2. The smoke outlet of the furnace 2 is connected to the upper part of the first tail flue 4 through the separator 3-1, and the outlet of the return device 3-2 is connected to the lower part of the furnace 2. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com