Compound anti-channeling gas-liquid separator

A gas-liquid separator, a composite technology, applied in separation methods, dispersed particle separation, combined devices, etc., can solve the problem that the separator cannot automatically control the gas-liquid flow rate, etc., achieve compact structure, high-efficiency separation, and prevent gas-liquid reaction. channeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

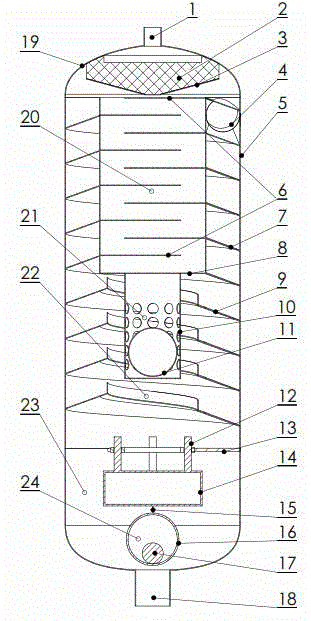

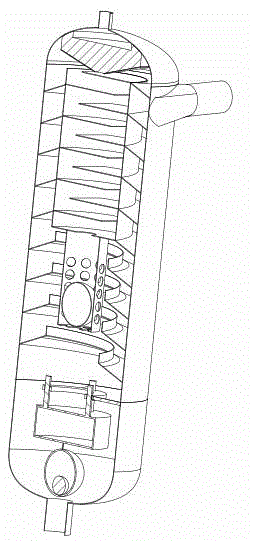

[0025] As shown in the figure, the composite anti-channeling gas-liquid separator includes an exhaust pipe 1, an adsorption filter 2, an inverted conical partition 3, a feed port 4, a shell 5, a baffle 6, a closed spiral Conduit 7, gas-liquid chamber partition 8, open spiral conduit 9, valve ball conduit 10, hollow valve ball a11, guide rail 12, centralizer 13, columnar float 14, connecting rod 15, hollow valve ball b16, heavy ball 17 , liquid discharge pipe 18, top cover 19, air cavity 20, exhaust self-control valve 21, separation chamber 22, liquid collection chamber 23 and liquid discharge self-control valve 24;

[0026] The top of the vertically placed cylindrical shell 5 is provided with a top cover 19, the upper part is provided with a feed inlet 4, and the inner side is provided with a closed spiral conduit 7 and an open spiral conduit 9, and the entrance of the closed spiral conduit 7 is connected to the feed inlet 4. Connected with each other, the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com