Method and system for recycling catalyst from coal chemical liquid waste

A technology of coal chemical industry and catalyst, applied in the field of waste liquid recovery, can solve the problems of coal chemical waste liquid discharge pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

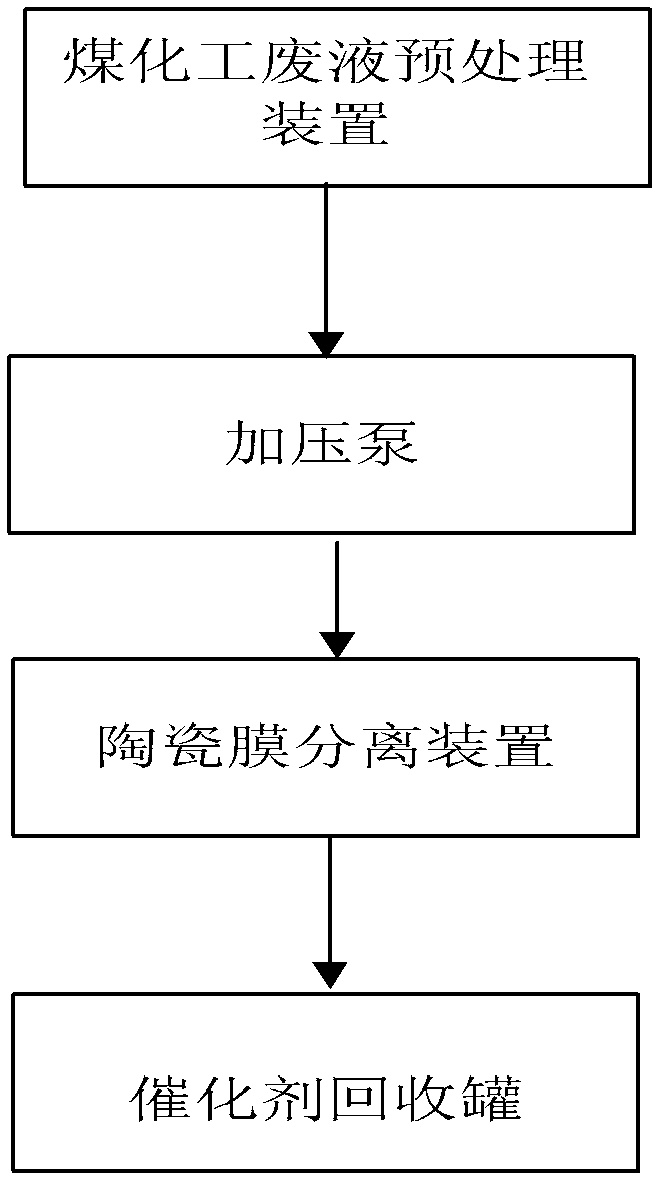

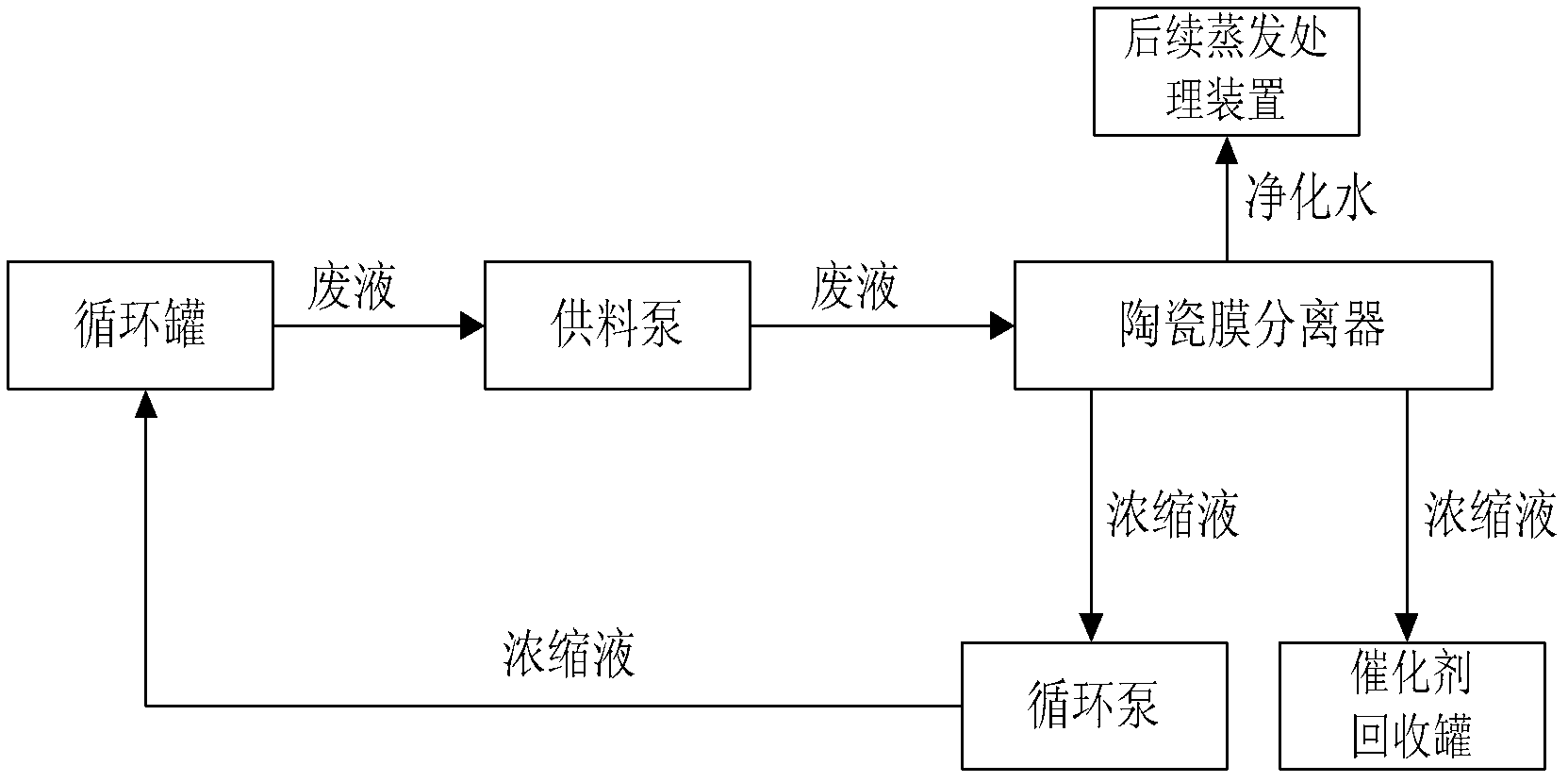

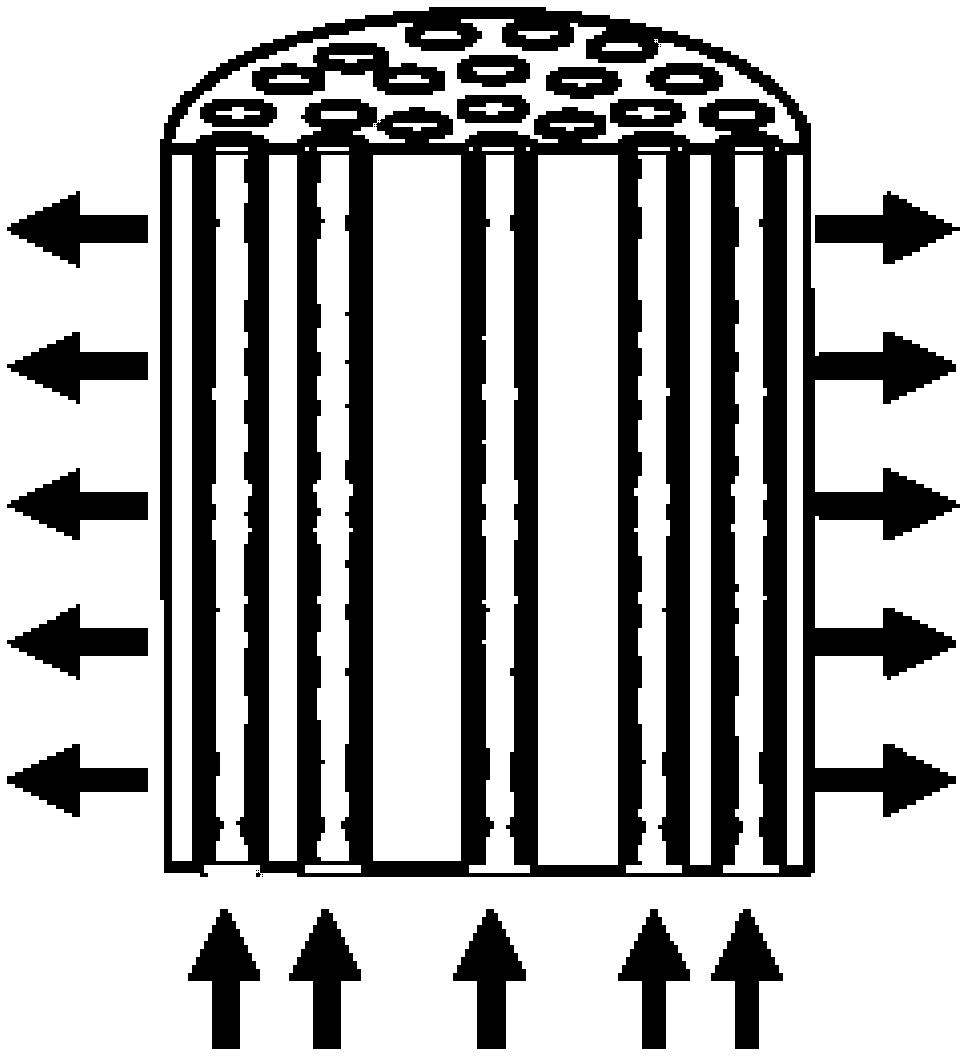

[0043] The method for recovering catalyst from coal chemical waste liquid of the present invention is used to recover and treat the original waste liquid generated in the catalyst production process. The system adopted is a waste liquid pretreatment device, a ceramic membrane separation device and a subsequent evaporation treatment device, wherein the waste liquid pretreatment device is a pre-sedimentation tank, and the ceramic membrane separation device includes a ceramic membrane separator, a circulation tank, a circulation pump and a catalyst recovery Tanks, ceramic membrane separators are commercially available products, and the filtration accuracy is over 90%. The subsequent evaporation treatment device is an evaporator unit. TSS (represents total suspended solids), Ca 2+ Concentration and TDS (stands for total dissolved solids) are expressed.

[0044] The coal chemical industry waste liquid (with a solid content of 25%) generated in the catalyst production process is pu...

Embodiment 2-6

[0046] The operation steps are the same as in Example 1, but the water quality of the coal chemical waste liquid is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com