Self-balancing throughflow type material returning device

A return feeder and self-balancing technology, which is applied in the field of mechanical engineering, can solve problems such as blockage of small slag blocks, and achieve the effect of preventing the backflow of the furnace air flow and ensuring good operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

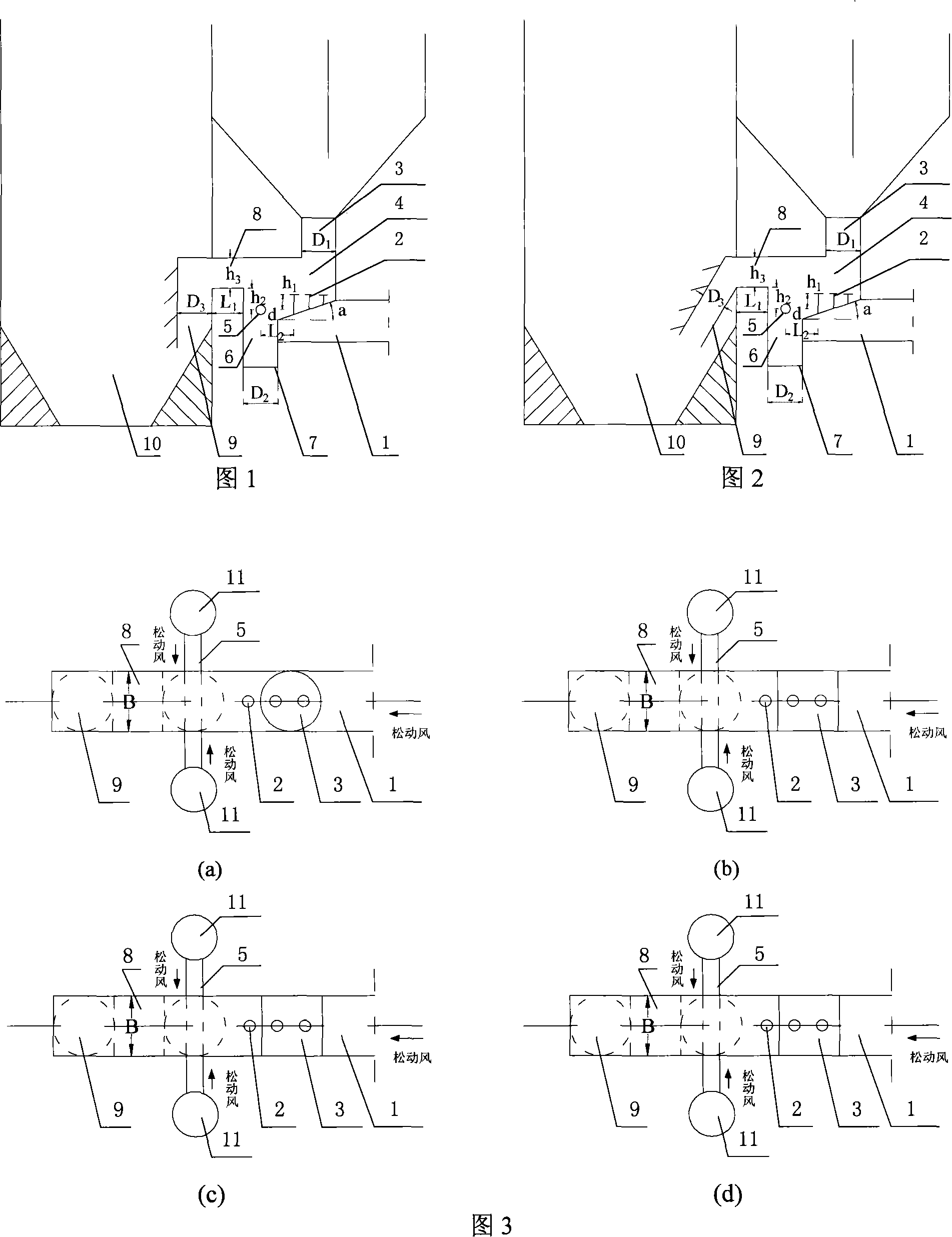

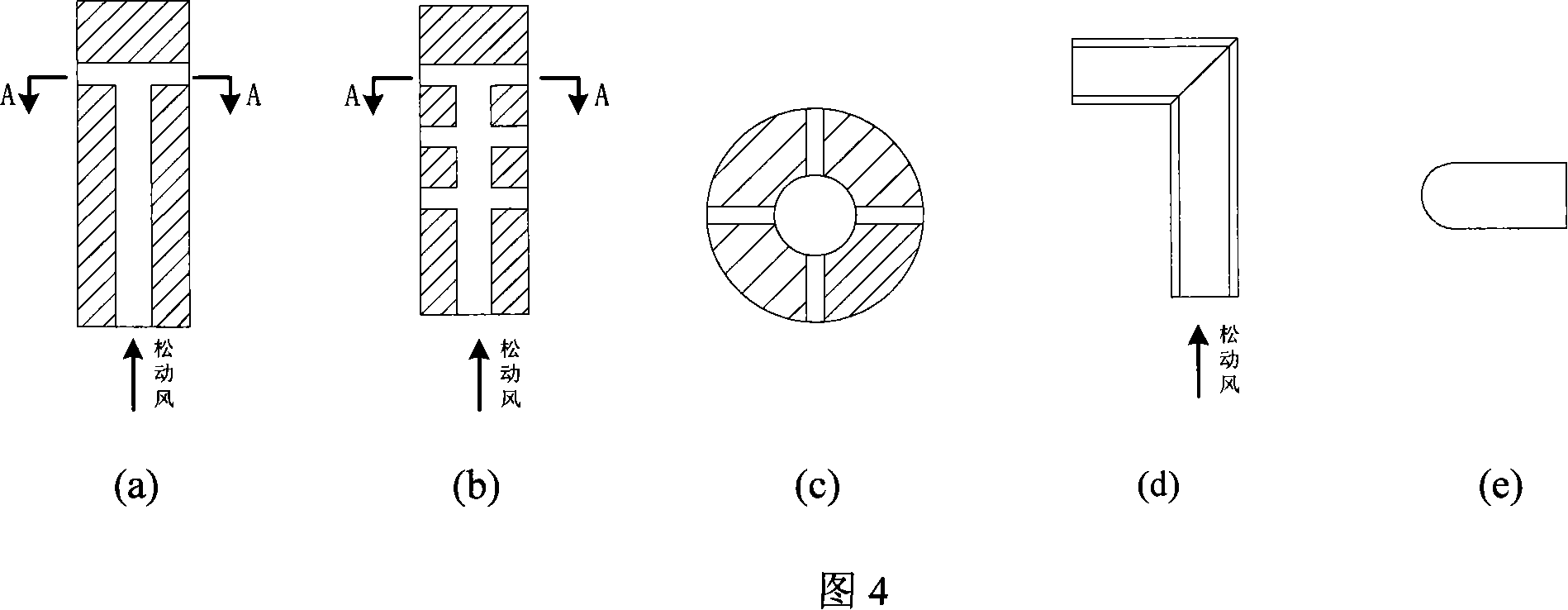

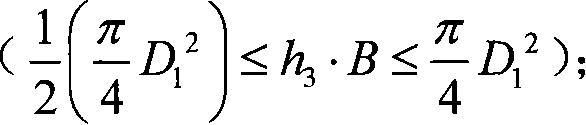

[0018] The present invention is composed of a blanking pipe 3, an adjustment section 4, an ash discharge pipe 6, a plate valve 7, a horizontal conveying section 8, an outlet section 9, a primary loosening air chamber 1 and a loosening air cap 2, a secondary loosening air chamber 11 and Loosen the air duct 5 components. The solid particle material separated by the material separator of the circulating fluidized bed boiler is filled with the drop pipe 3, which is cylindrical or square, and its height is the lowest to prevent the particle material in it from flowing freely. The blanking pipe is connected with the adjustment section 4, and the horizontal inclination angle α of the bottom plate of the adjustment section 4 is 0-15°, and a first-level loose wind cap 2 is arranged on it. The first-level loose air cap 2 is a cylindrical (non-directional) air cap or a directional air cap, which is located within the center line of the blanking pipe, and is distributed by the first-level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com