Composite graphite burning torch

A technology of composite graphite and ignition gun, which is applied in the direction of combustion ignition, intermittent spark ignition, lighting and heating equipment, etc., can solve the problems of poor sealing effect, poor corrosion resistance, poor pressure capacity, etc., and achieve an increase in flame concentration , Improve the success rate of ignition and the effect of increasing the air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

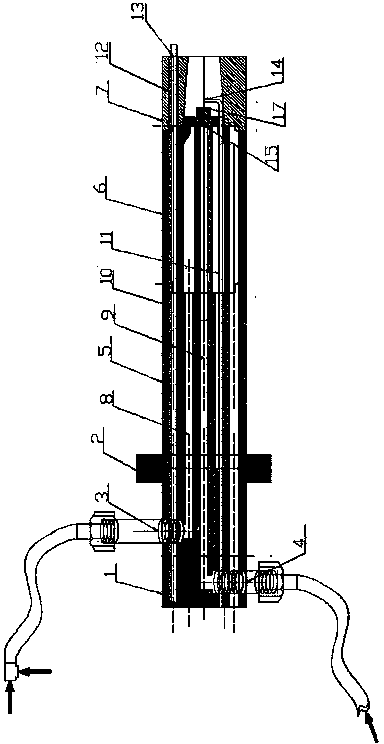

[0028] Such as figure 1 with figure 2 Shown, a kind of composite graphite ignition gun of the present invention comprises gun body, gun body furnace inner section and furnace outer section 1, and gun body is a cylindrical body, is sleeved between the furnace inner section and furnace outer section 1 and is used for being installed in The installation flange 2 of the furnace mouth;

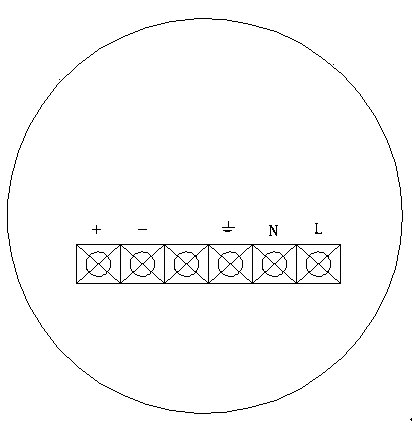

[0029] The outer section 1 of the furnace has an air interface 3 and a hydrogen interface 4, and a circuit board and a high-voltage pulse generator are installed inside it;

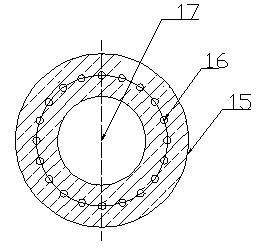

[0030] The inner part of the furnace is composed of the first sleeve 5, the second sleeve 6 and the combustion chamber 7, which are inlaid and connected in sequence, and the long axis direction of the first sleeve 5 and the second sleeve 6 is extended to communicate with the air interface 3 An air passage 8, a hydrogen passage 9 connected with the hydrogen interface 4, a pinhole A10 for installing a flame probe and a pinhol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com