Pneumatic actuating mechanism for one-way damping valve

A pneumatic actuator, one-way damping technology, applied in engine components, valve operation/release devices, valve details, etc., can solve the problems of reduced energy efficiency of catalytic cracking units, poor sealing performance of one-way damping valves, mechanical collisions, etc. , to avoid the excessive pressure loss of the pipeline, increase the closing torque, and close the zero leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

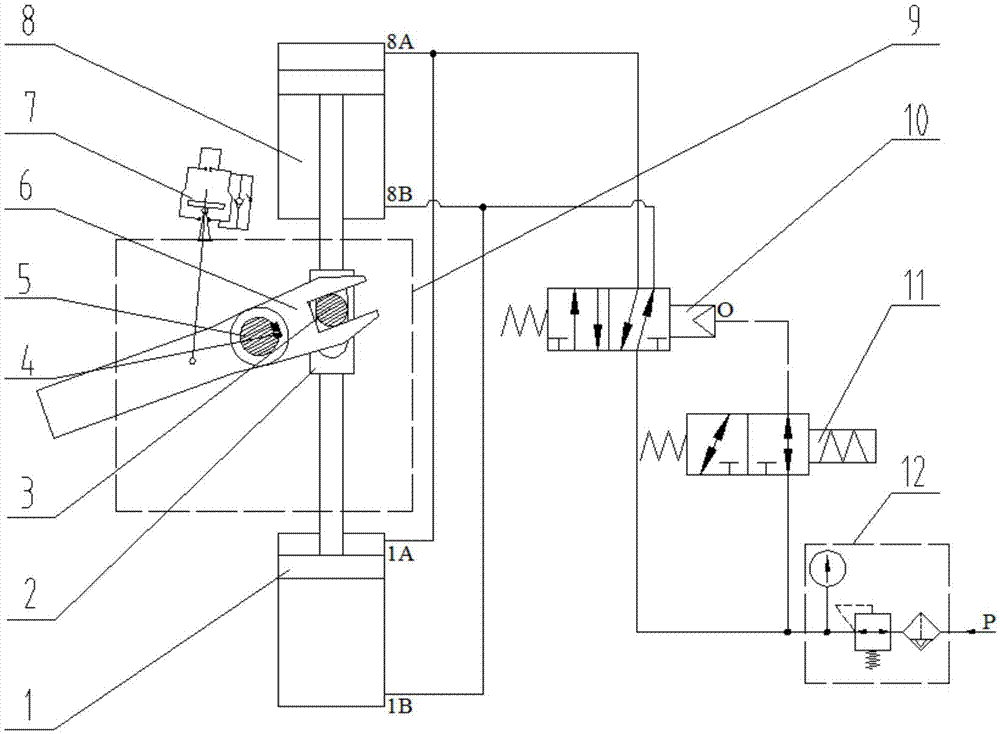

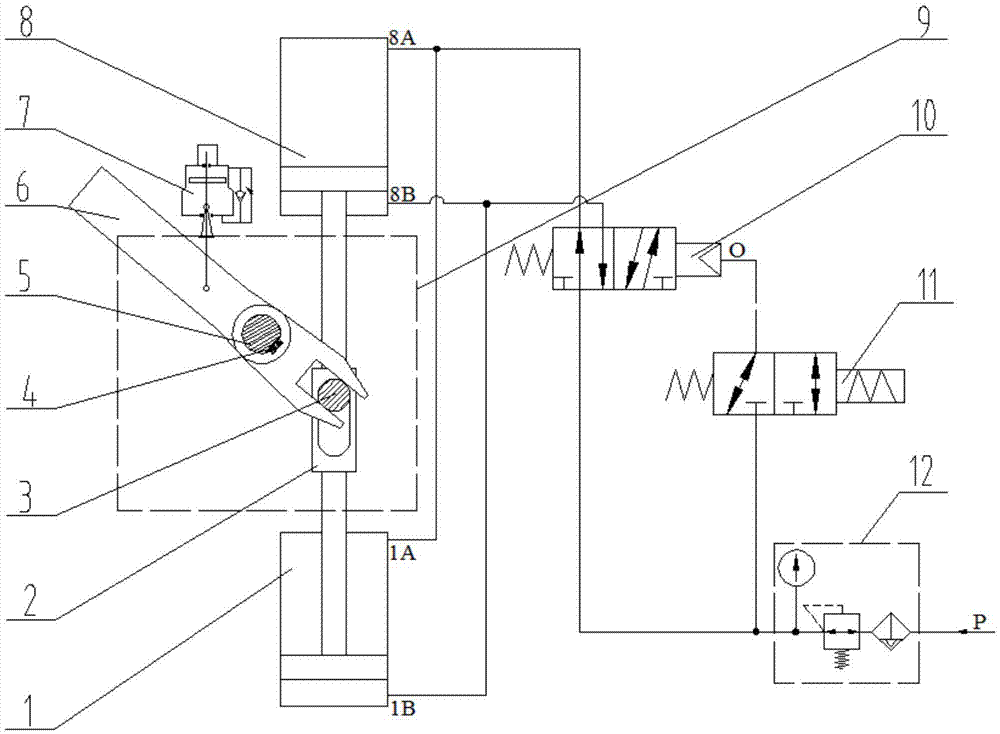

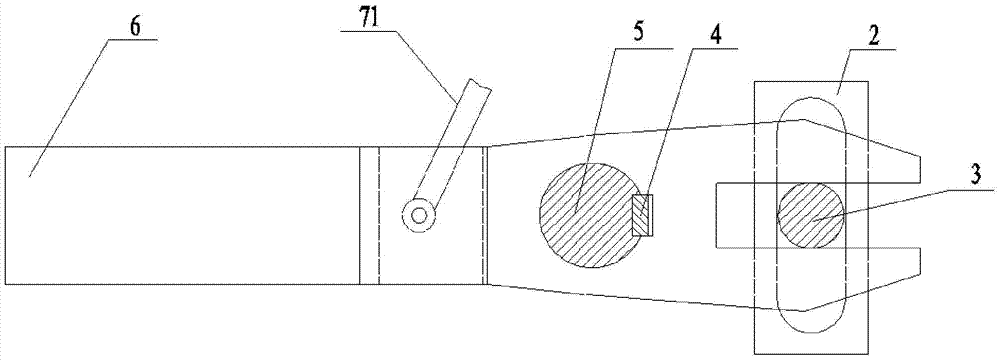

[0044] An embodiment of the present invention provides a pneumatic actuator for a one-way damping valve, the pneumatic actuator is connected to the valve shaft of the one-way damping valve, see figure 1 , and combined with figure 2 and image 3 , the pneumatic actuator includes: a first cylinder 1, a second cylinder 8, a shift fork shaft 3, a shift fork 6 and a cylinder reversing control unit; the rod of the shift fork 6 is fixedly connected to the valve shaft 5 of the one-way damping valve; The cylinder reversing control unit is used to control the reversing of the first cylinder 1 and the second cylinder 8; wherein, the pneumatic actuator also includes: a clutch mechanism 2; the clutch mechanism 2 is a cylinder, and the clutch mechanism 2 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com