Gate valve and manufacturing process thereof

A manufacturing process and gate valve technology, which is applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of time-consuming and labor-intensive, air holes, trachoma, and increased processing difficulty, and achieve the advantages of easy opening, reduced labor intensity, and reduced machining the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

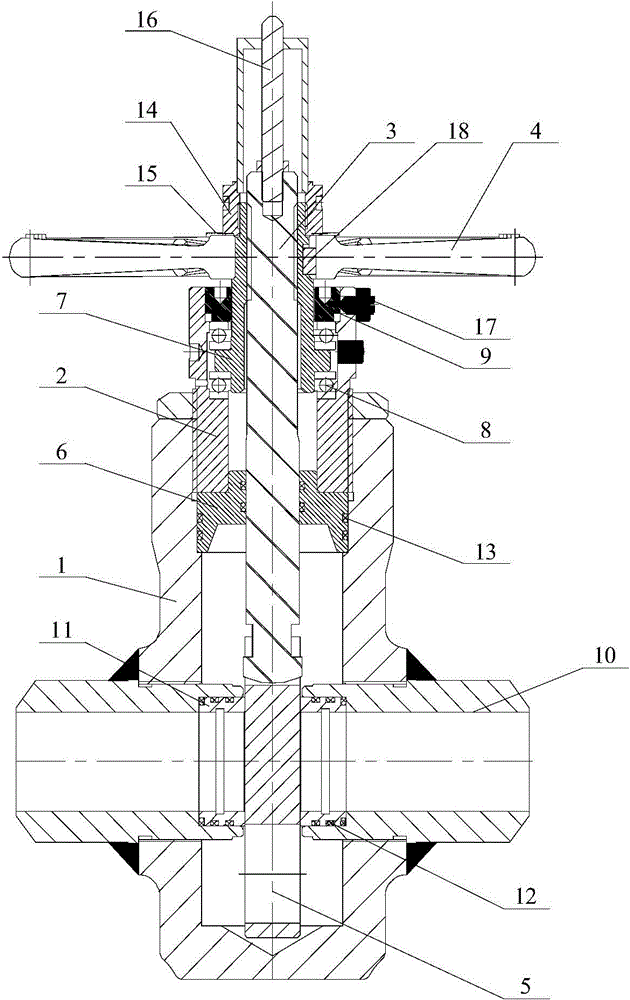

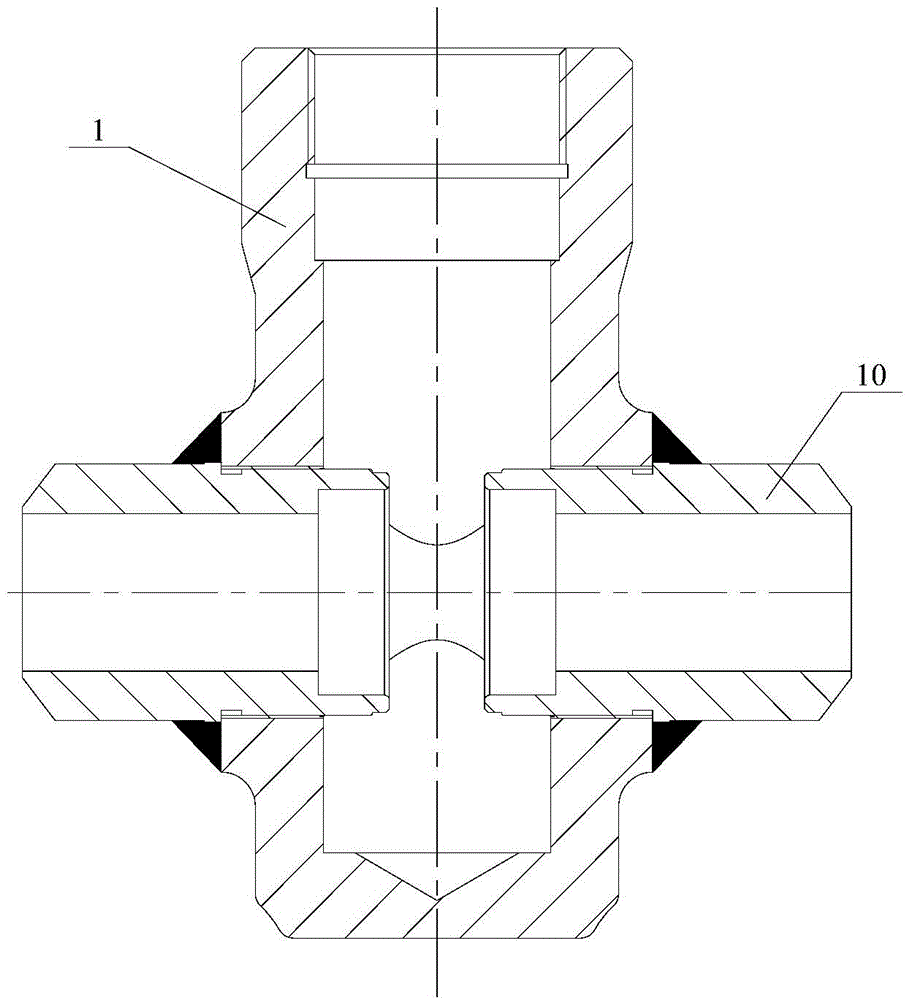

[0036] Such as figure 1 and figure 2 As shown, the present invention provides a gate valve, comprising a valve body 1 with a three-way structure, the upper end of the valve body 1 is connected with a valve cover 2 through a valve port, the valve cover 2 is provided with a through hole, and the valve stem 3 passes through the through hole It penetrates into the valve body 1, and the upper end of the valve stem 3 is vertically connected with the handwheel 4, and the lower end is connected with the valve plate 5 for controlling opening and closing. The valve body 1 is fitted with a stuffing box 6, and the valve cover 2 is pressed tightly On the stuffing box 6, the top of the bonnet 2 is connected with a stem nut 7, and a positioning sleeve 8 is arranged inside the bonnet 2 and between the valve stem nut 7, and a number of thrust ball bearings are arranged in the locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com