Conveying device capable of achieving automatic turnover of box type goods

An automatic flipping and conveying device technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of cargo jamming, cargo wear, manual flipping of cargo, etc., to avoid pollution and wear, solve jamming, The effect of quick flip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

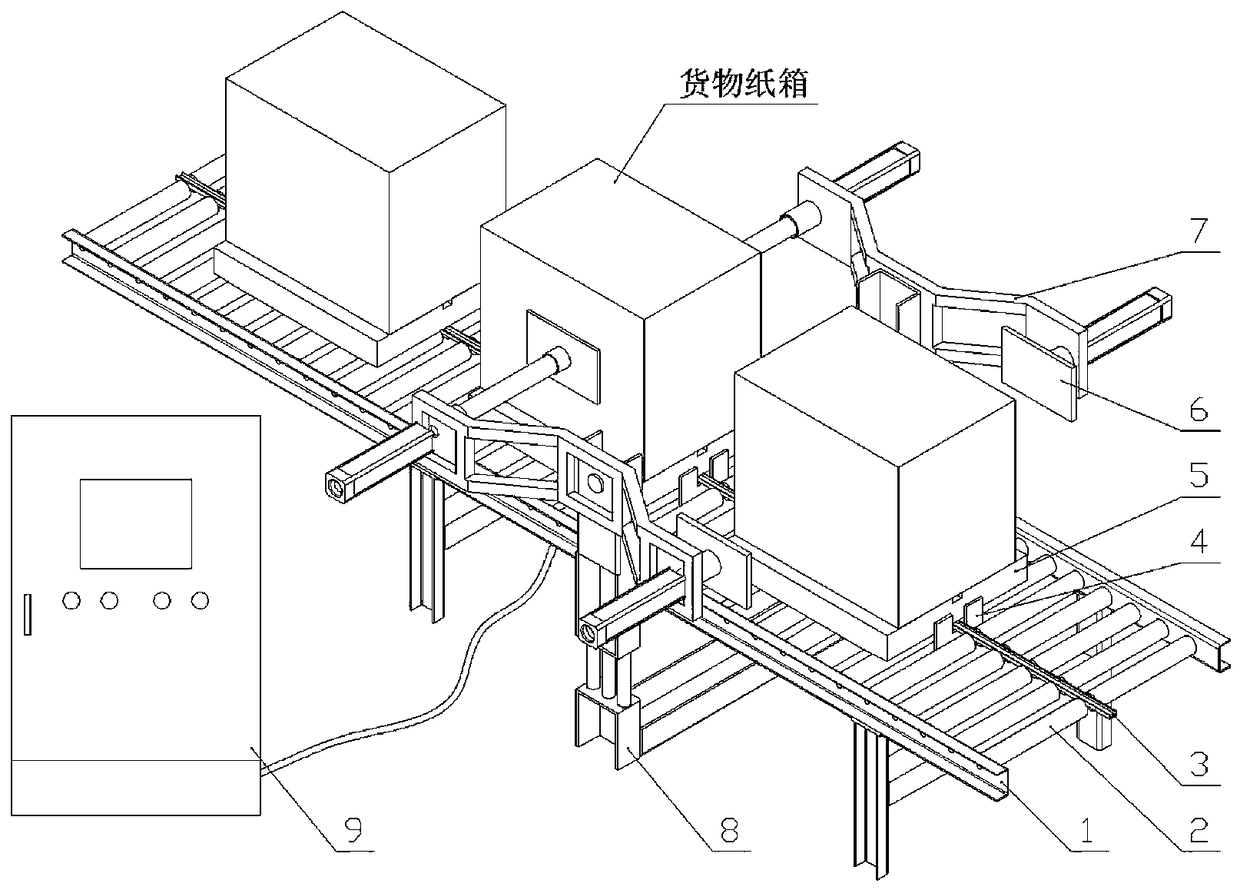

[0021] Installation of conveying device: install the conveying line support (1) to the predetermined place, and level the upper surface; install the accumulative roller (2) and related motor and other parts on the conveying line support (1) with bolts; the guide groove (3) Fixed to the center of the conveying surface of the conveyor line support (1); the tray baffle (4) and its driving cylinder are installed on the conveyor line support (1) with bolts; the flip support (8) is fixed to the ground with expansion bolts, Before installation, it is necessary to adjust its relative position to the conveying line support (1), so that the center of the overturning support (8) coincides with the center of the conveying line support (1); put the overturning arm (7), box chuck (6) and related The components are bolted to the flip bracket (8).

[0022] Operation process: power on the conveying device and adjust to the required conveying speed; place the cargo pallet (5) on the conveying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com