Rotating disk type feeding system of biomass burner

A feeding system, turntable technology, used in combustion methods, combustion equipment, fuel supply, etc., can solve problems such as many failures, short service life, and reduced safety, and achieve safe and reliable operation, long service life, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with accompanying drawing, the present invention is described in further detail:

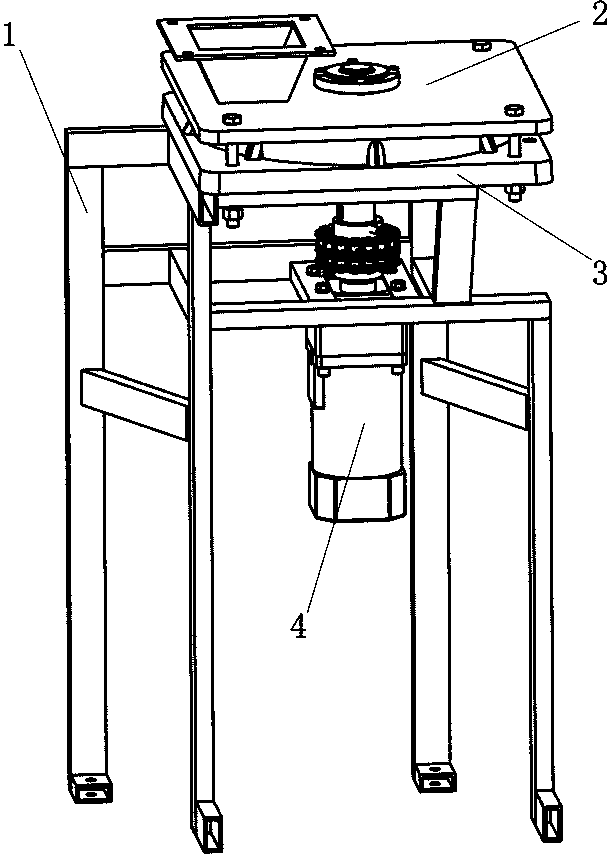

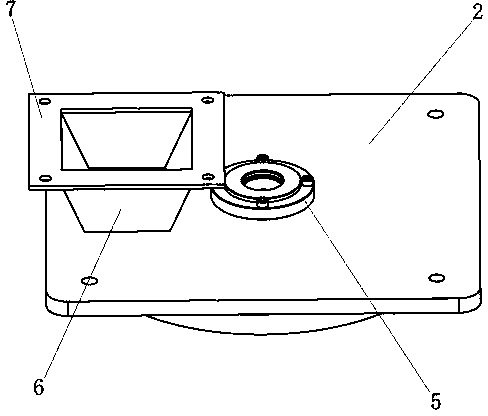

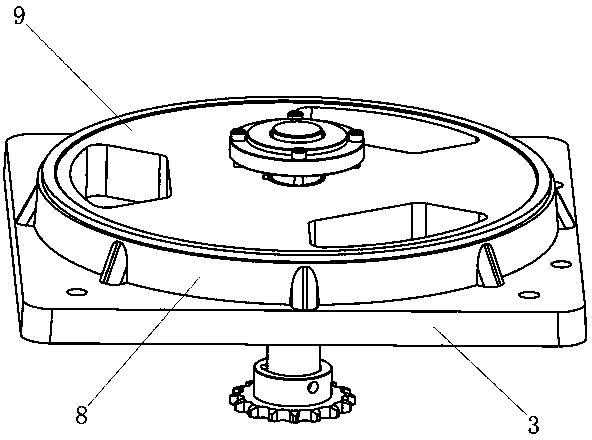

[0026] Such as figure 1 A turntable feeding system for a biomass burner is shown, which is characterized in that: the turntable feeding system includes a material rack 1, a speed regulating motor 4, a feeding tray 2, a feeding tray 3 and a transmission shaft 10, the The above-mentioned upper material tray 2 and the lower material tray 3 are connected and fixed on the material rack 1 through the through hole in the middle of the upper and lower material trays through the transmission shaft 10; There is an upper bearing end cover 5; a circular ring 8 is welded on one side of the lower material tray 3, and a turntable 9 is arranged in the said circular ring; the lower material tray 3 and the upper material tray 2 have corresponding connection holes, The lower tray 3 and the upper tray 2 are positioned and fixed through the connecting hole 15 by bolts.

[0027] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com