A hydrogen-oxygen generating system

A hydrogen-oxygen system technology, applied in the direction of using liquid separation agent, dispersed particle filtration, electrolysis process, etc., can solve the problems of spark tempering, complex overall structure, and large volume, so as to prevent tempering and simplify the overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings.

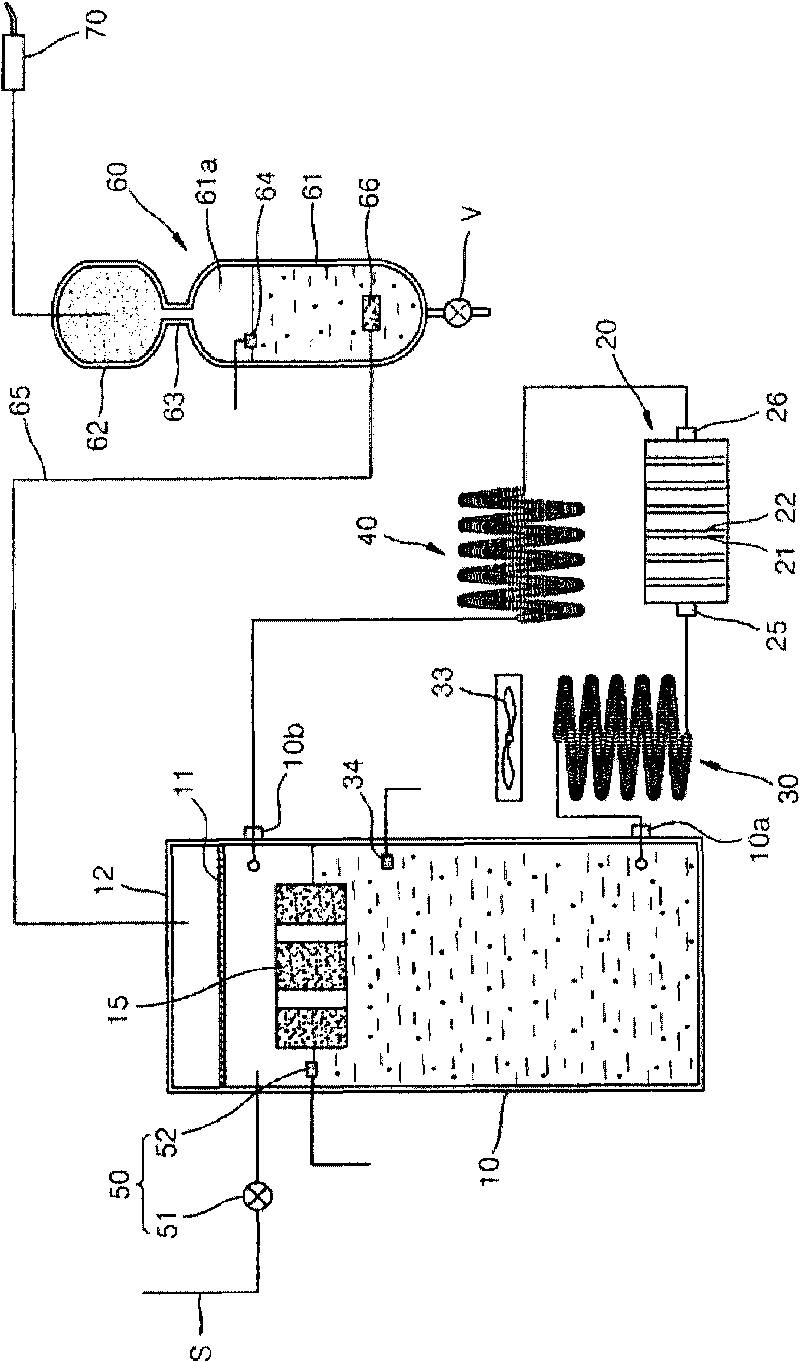

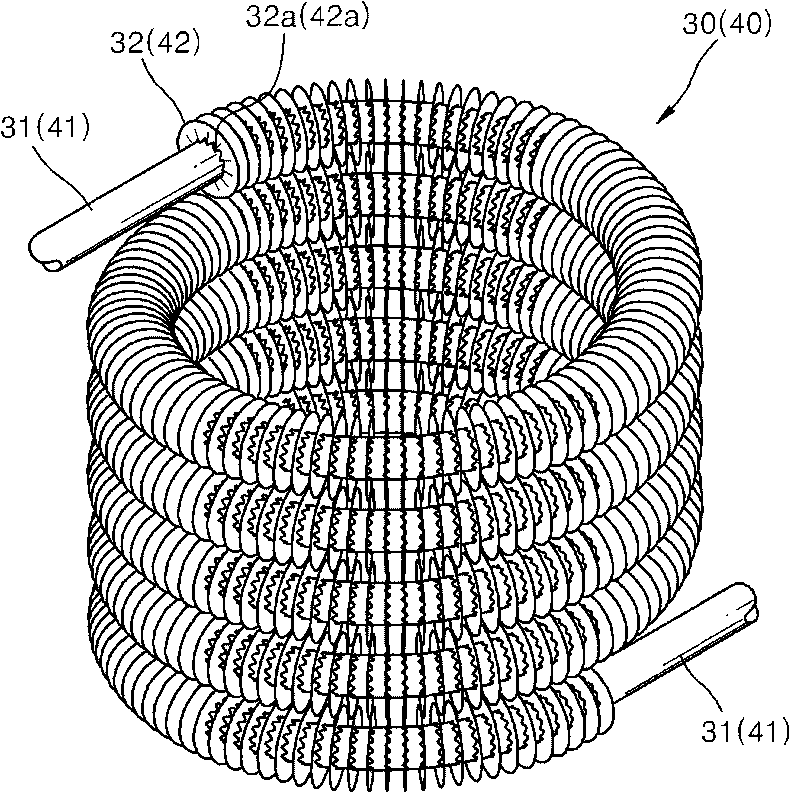

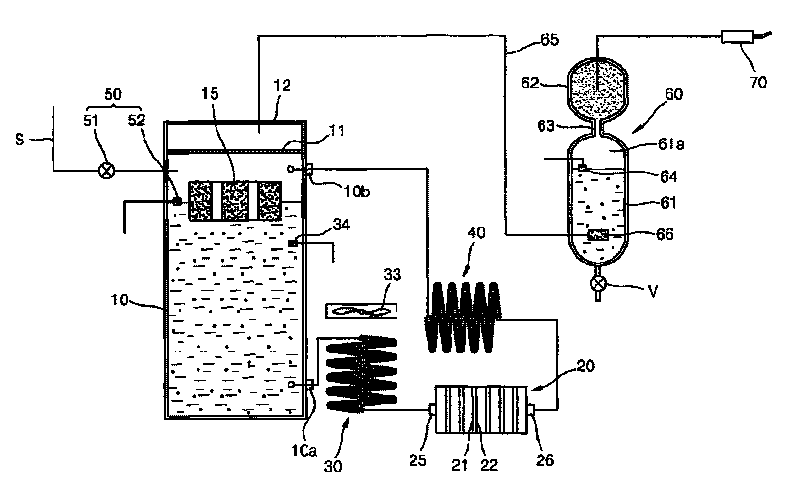

[0031] figure 1 It is a schematic diagram showing the detailed structure of the oxygen-hydrogen production system of the present invention, figure 2 yes means figure 1 The schematic diagram of the detailed structure of the first heat dissipation supply pipe and the second heat dissipation supply pipe in .

[0032] As shown in the figure, the oxygen gas production system provided by the present invention includes a water storage collection tank 10, an electrode assembly 20, a first heat dissipation supply pipe 30, a second heat dissipation supply pipe 40, a water level maintaining device 50, and an anti-reflux filter assembly 60 and nozzle 70.

[0033] The water storage collection tank 10 is used to store water and collect hydrogen and oxygen gas; the electrode assembly 20 is built with a plurality of electrodes 21, 22 and is formed with an inflow port 25 for enteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com