Improved screw feeder of raw biomass material incinerator

A technology of screw feeder and biomass raw material, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of easy ignition, fire, explosion accidents, etc., and achieve the effect of preventing backfire phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

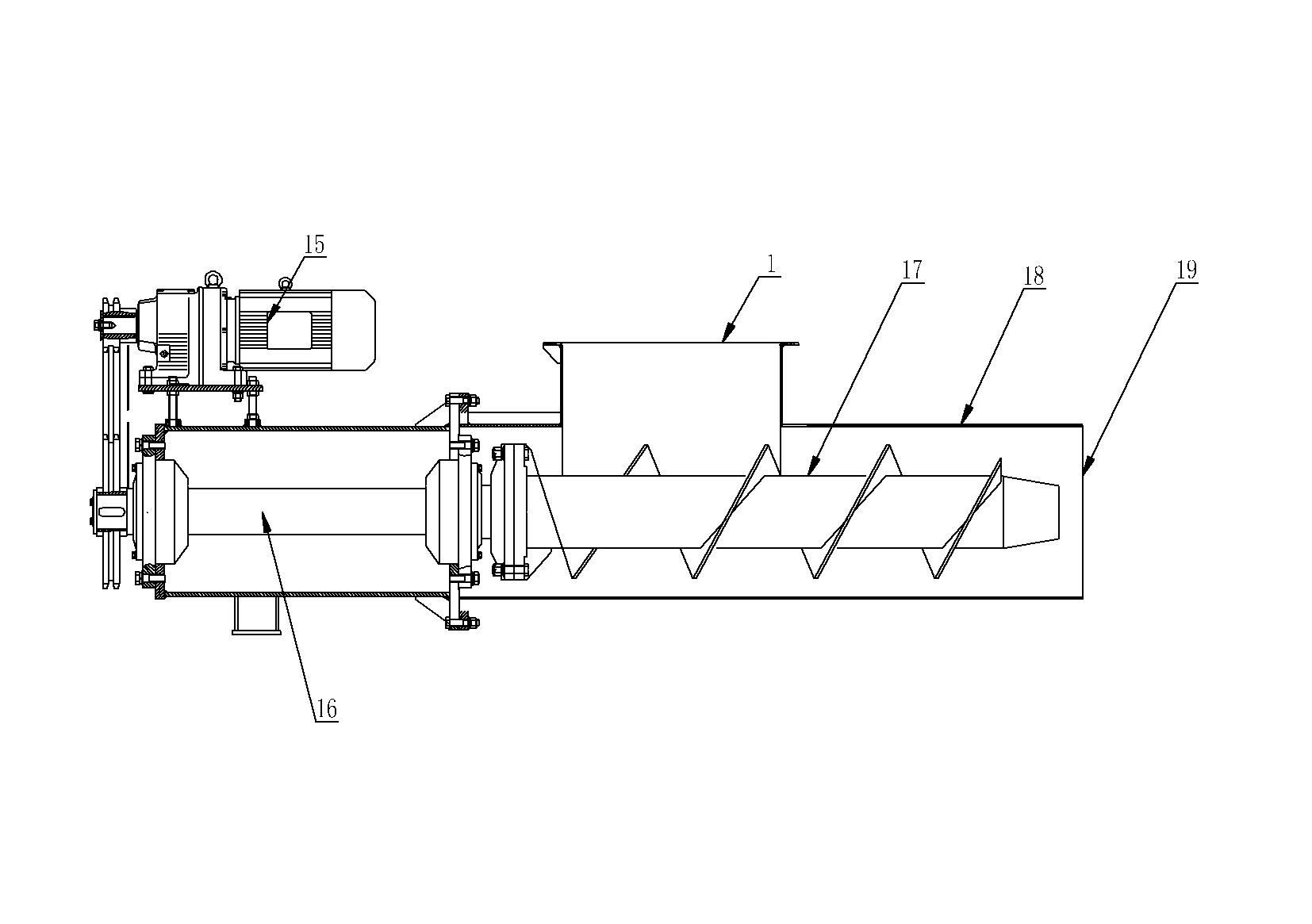

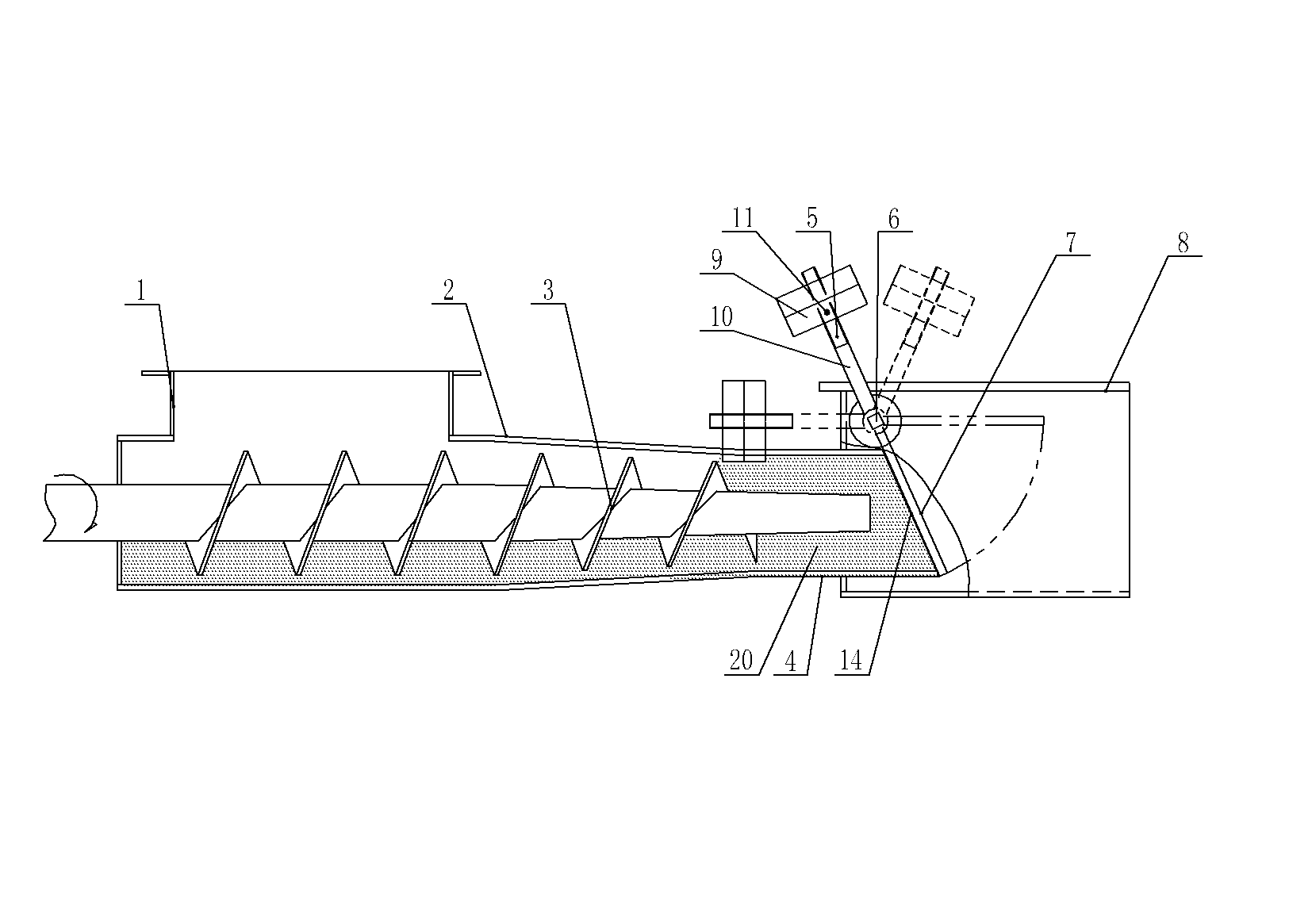

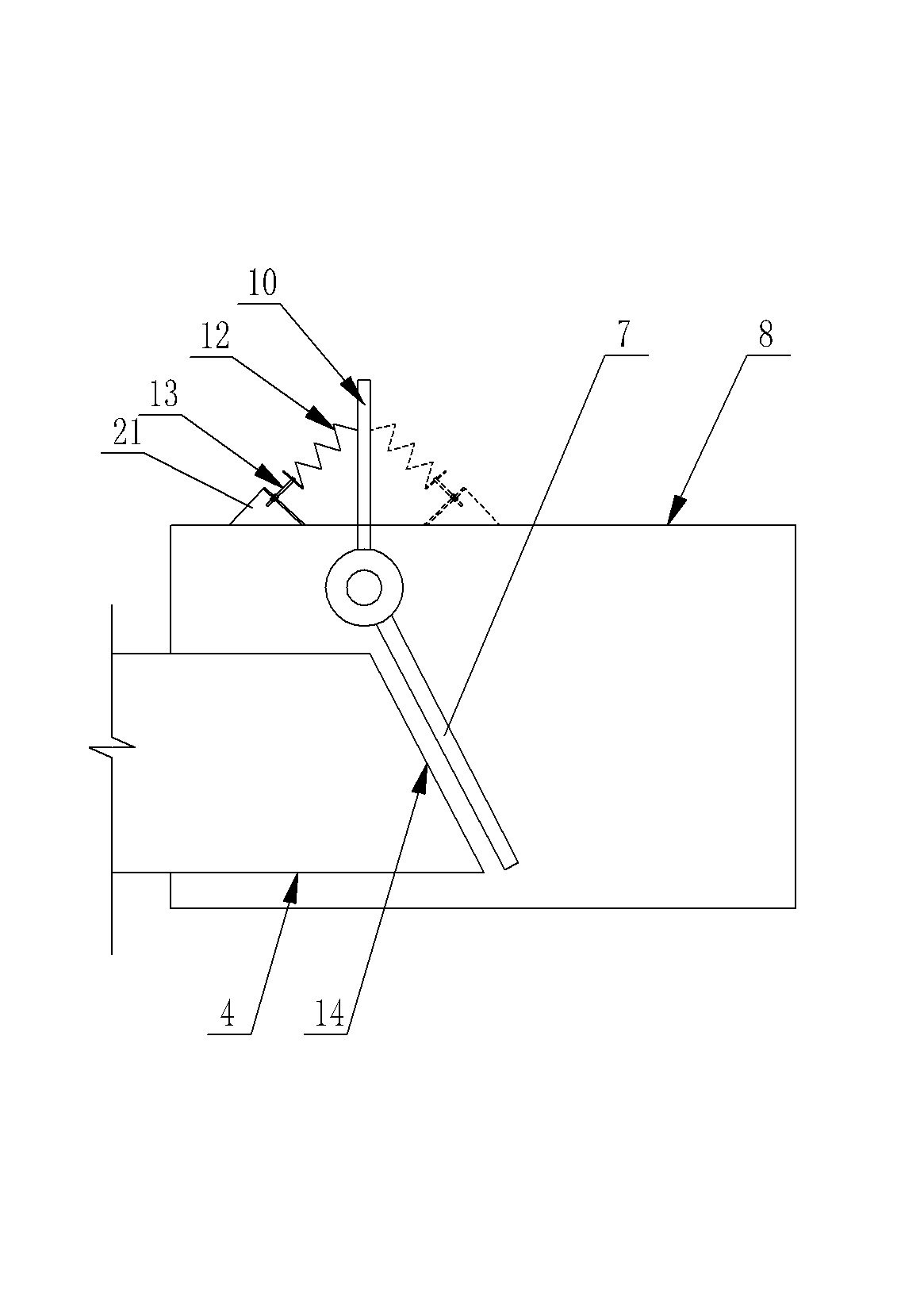

[0013] See figure 2 , the present invention includes a feeder housing 2 and a screw shaft 3, the feeder housing 2 is provided with a feed port 1, the discharge port 14 of the feeder housing 2 is connected to the hopper 8, and the screw shaft 3 is driven by The device drives and passes through the feeder housing 2, the discharge port end of the feeder housing 2 is provided with a plug section 4, the part of the screw shaft 3 located at the plug section 4 is not equipped with a screw blade, and the discharge hopper 8, located at A damping door rotating shaft 6 is installed above the discharge port, and a damping door 7 is installed through the damping door rotating shaft 6 at the discharge port 14, and a damping device 5 is also connected to the damping door rotating shaft 6, and the end face of the discharge port 14 is an inclined plane. In the actual production process, when the pressure in the furnace is low and the material plug does not need to be pressed very tightly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com