Pneumatic valve using air cylinder as actuator

A technology of actuators and cylinders, applied to engine components, valve details, valve devices, etc., can solve problems such as valve jamming, potential safety hazards, and elastic decline of return springs, so as to solve the problem of insufficient spring force, eliminate potential safety hazards, and increase the effect force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

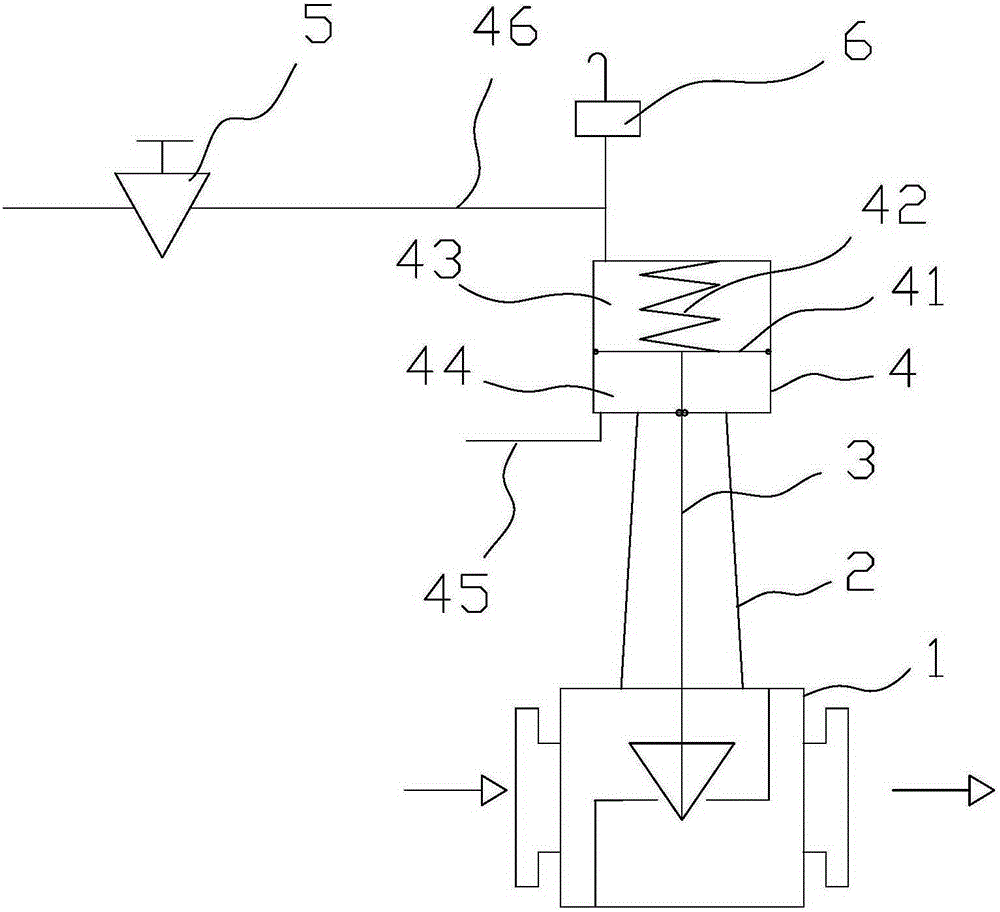

[0017] Such as figure 1 As shown, the present invention includes a valve body 1, a valve rod 3, and a cylinder 4 that controls the reciprocating action of the valve rod 3. The cylinder 4 is fixed to the valve body 1 by a bracket 2, and one end of the valve rod 3 is connected with the piston rod of the cylinder 4. The piston 41 in the cylinder 4 divides the inner cavity of the cylinder into two working chambers, one of the working chambers 43 is provided with a return spring 42, the other working chamber 44 is in communication with the control air circuit through the air pipe 45, and the cylinder 4 is equipped with a return spring The exhaust port of the working chamber 43 of 42 has an air inlet pipe 46 in communication with the control air path through the pressure reducing filter 5, and a pressure release valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com