Novel cold flame spraying decoration device

A new type of fireworks technology, applied in the direction of simulating fireworks, can solve the problems of unstable spray effect, cumbersome equipment, high cost, etc., and achieve the effect of reducing the difficulty of design and control, omitting the feeding structure and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

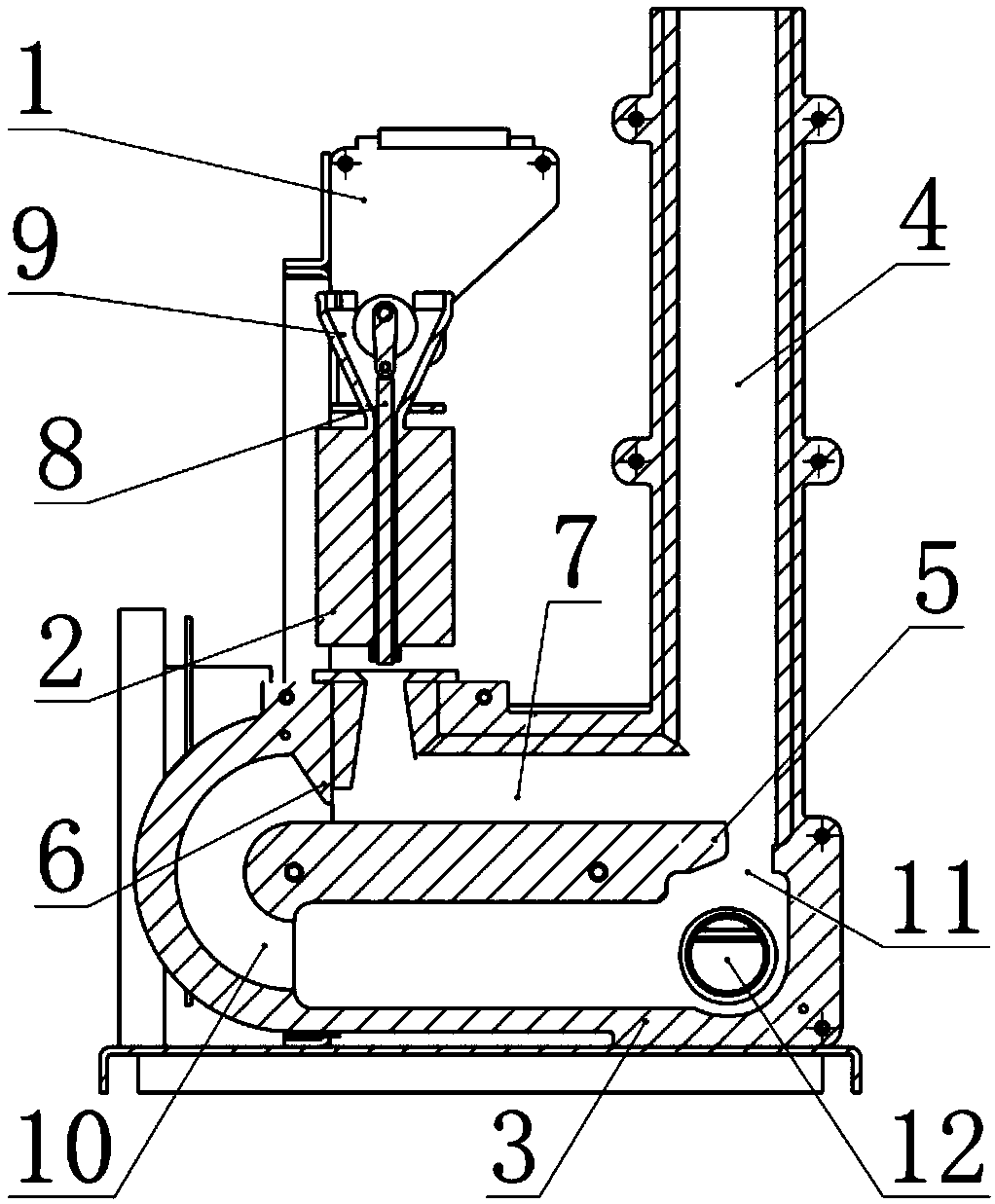

[0025] The novel cold pyrotechnic spraying device of the present embodiment comprises a blanking mechanism, a heating mechanism 2, a feeding and blowing mechanism and an ejection mechanism, such as figure 1 As shown, the unloading mechanism includes a storage hopper 1 and a receiving hopper 9 arranged in sequence, a punching needle 8 is arranged at the center of the receiving hopper, and a heating mechanism 2 is arranged outside the lower part of the receiving hopper 9, which can be set by a spiral heating wire or an electromagnetic induction heating coil. Around the described receiving hopper; the ejection mechanism includes the ejection pipe 4; the feeding and blowing mechanism 3 includes a blower fan (not shown in the figure), an air inlet 12, an air duct one 10 and an air duct two 11, and the horizontal feeding The pipe 7 is connected with the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com