Compliant device and method for realizing peg-in-hole assembly

A compliant, shaft hole technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as assembly hole wall jamming, and achieve the effect of improving assembly quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

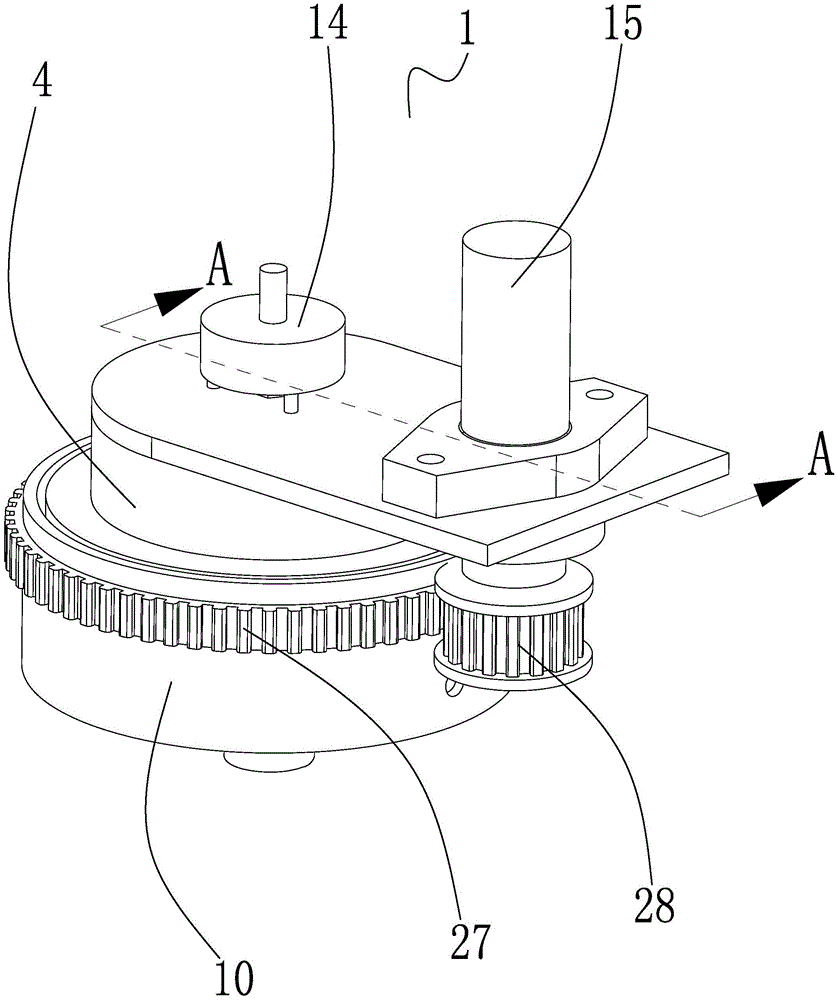

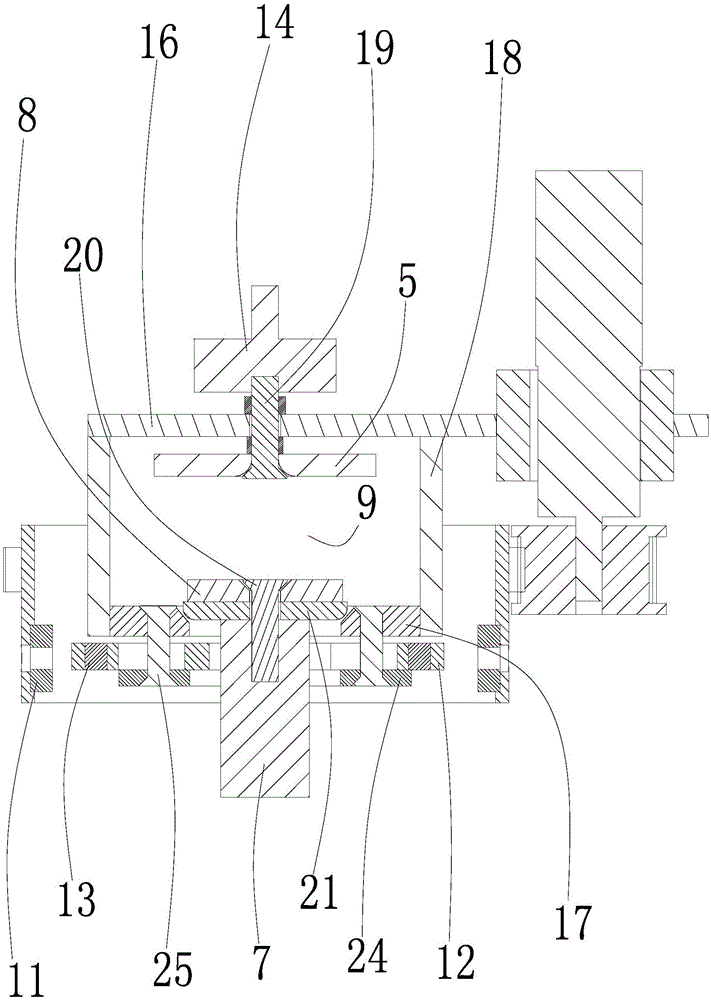

[0030] Please see attached figure 1 And attached figure 2 , a compliant device 1 for shaft-hole assembly, comprising an active compliant part 2 and a passive compliant part 3,

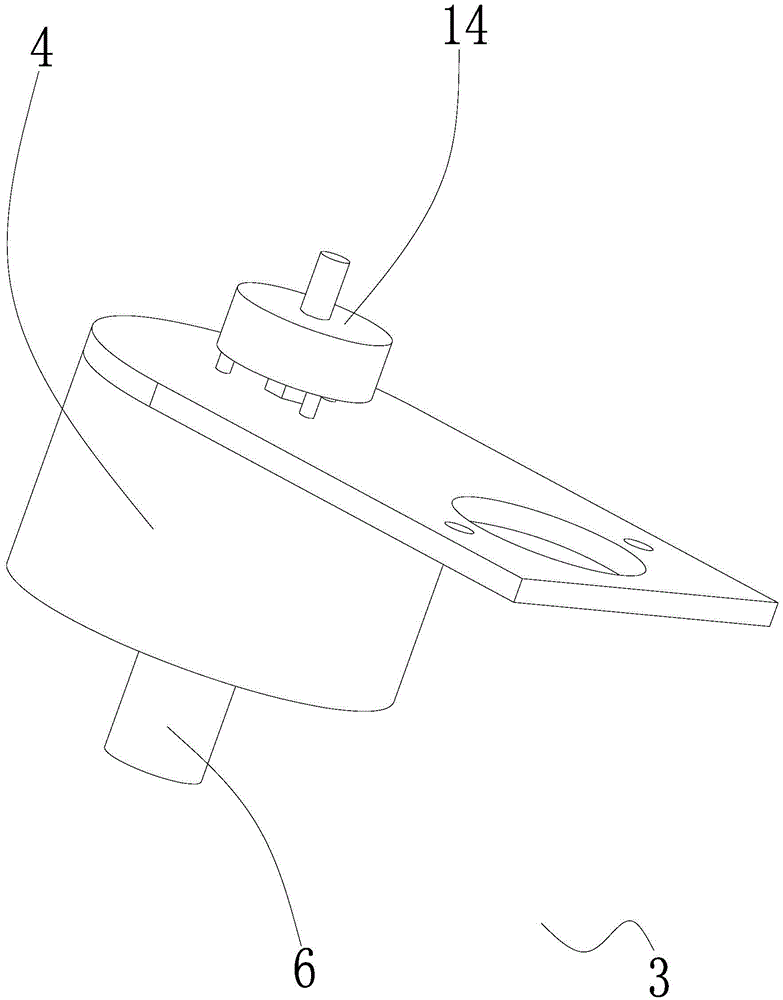

[0031] The passive compliance part 3 includes a housing 4, a first magnet 5 is provided on the upper side of the housing 4, and a compliance unit that can move up and down in the axial direction relative to the first magnet 5 and can at least be connected to the assembly shaft is sleeved on the lower side of the housing 4. The connecting part 6, the flexible connecting part 6 includes an end connector 7 passing through the bottom of the housing 4 from the inside of the housing 4, and the end connector 7 is provided with a polarity opposite to the first magnet 5. The same second magnet 8, a buffer space 9 is provided between the first magnet 5 and the second magnet 8;

[0032] The active compliance part 2 includes a rotatable rotating sleeve 10 sheathed outside the housing 4 , and magnets 11 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com