Rotating-valve-type hydrodynamic impactor

A hydraulic impactor and rotary valve technology, which is applied to the driving device for drilling in the borehole, earthwork drilling, drilling equipment, etc., can solve the problems of long service life and large impact energy, and achieve long service life and impact High energy and the effect of improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

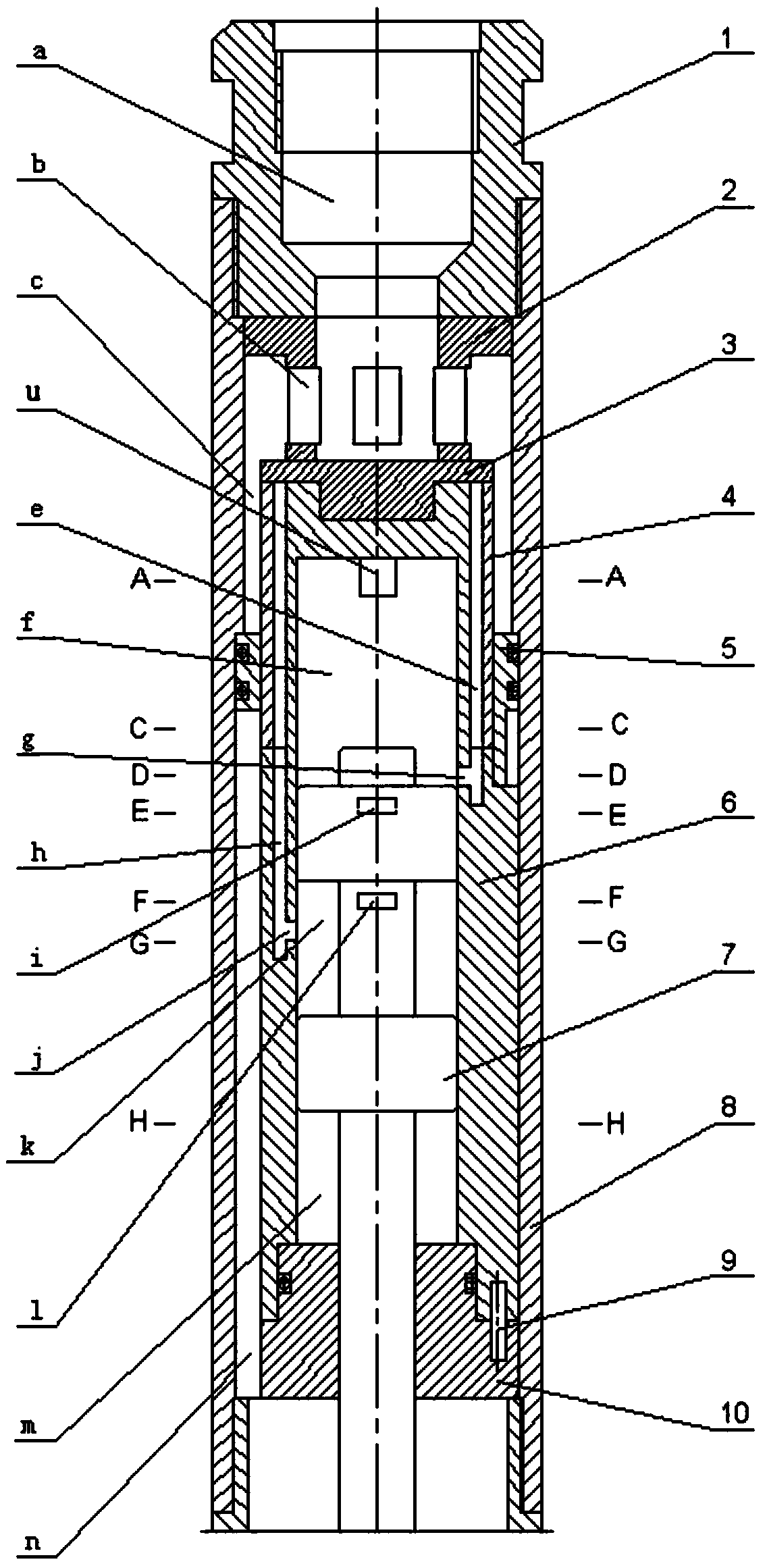

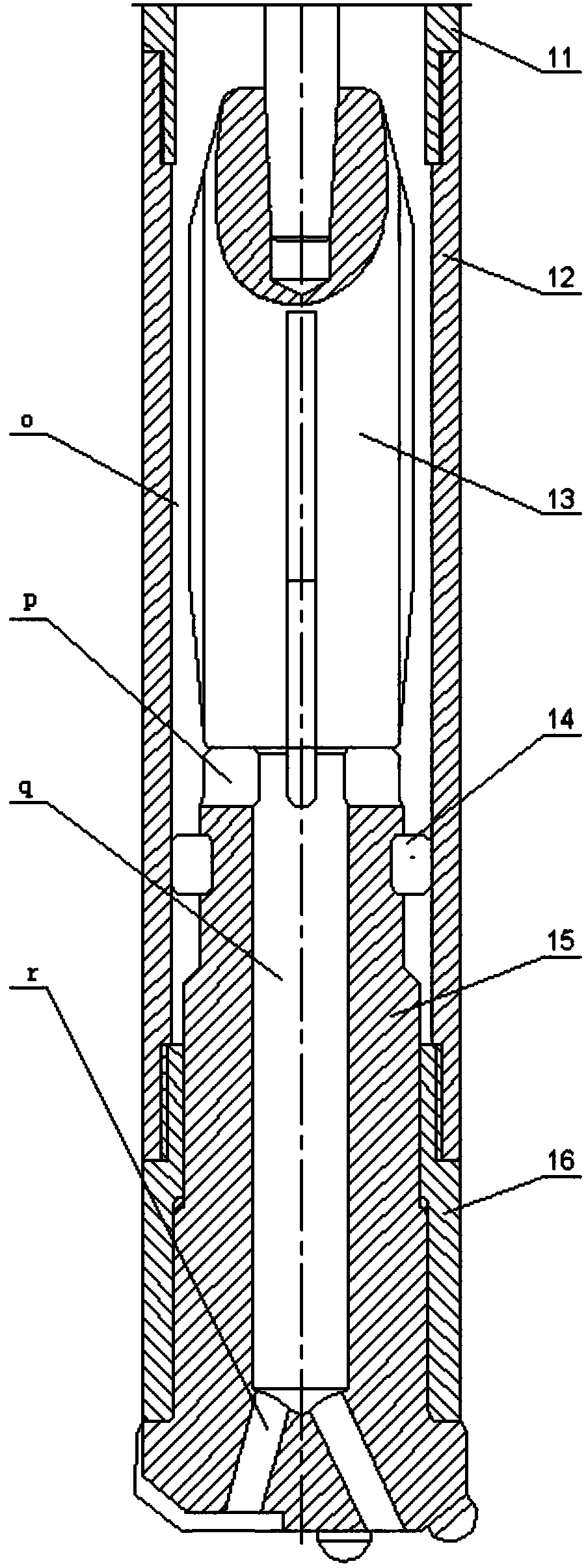

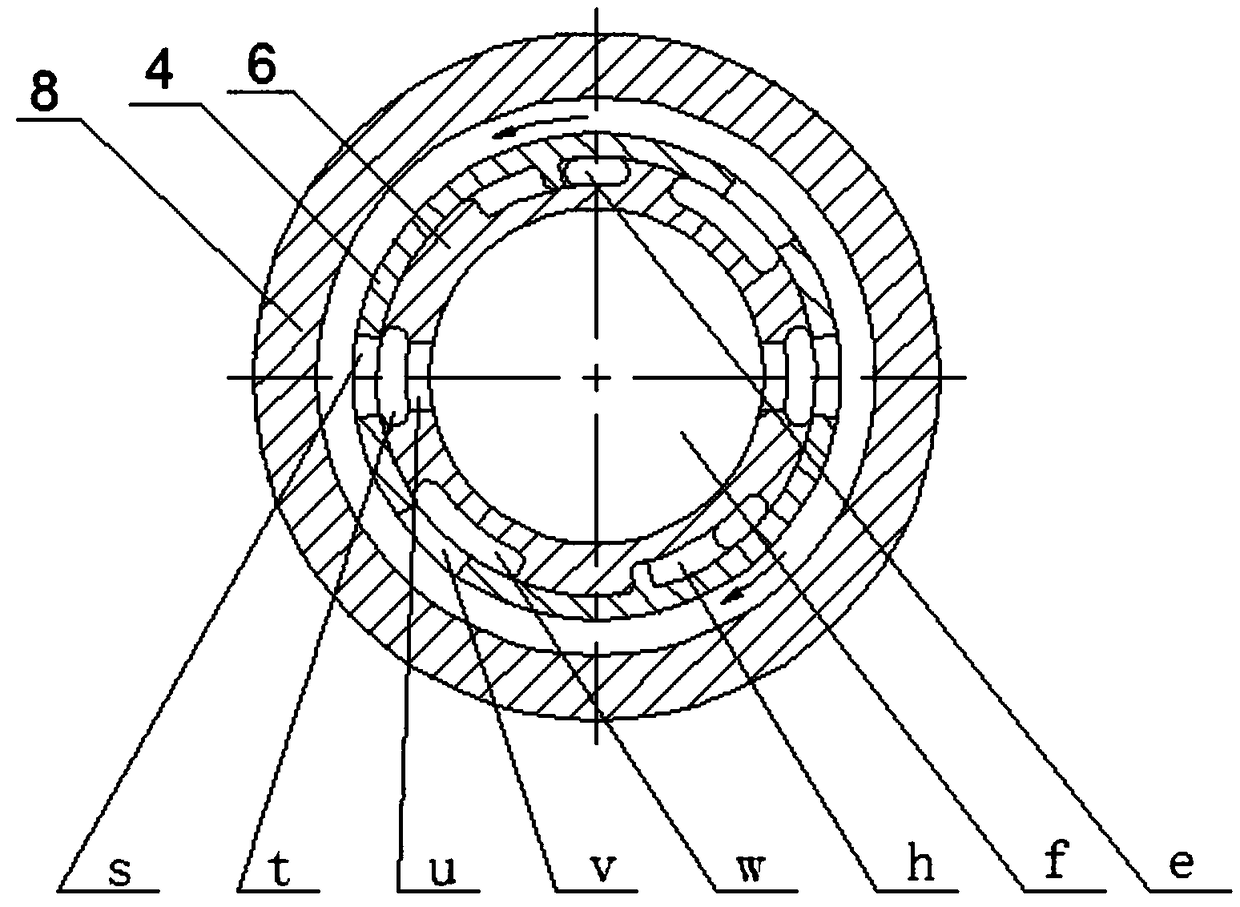

[0032] As shown in Figure 1, the present invention includes an upper joint 1, a rotor 4, a cylinder body 6, a piston 7, a middle joint 11, a hammer body 13 and a drill bit 15;

[0033] The upper joint 1 is connected with the upper outer pipe 8 through threads. The upper joint 1 fixes the gland 2 and the valve cover 3 on the upper end surface of the cylinder body 6 in turn. The valve cover 3 restricts the axial serial movement of the rotor 4. The central part of the gland 2 There is a channel communicating with the a-th fluid channel in the center of the upper joint 1, and the b-th fluid channel of the c-th fluid channel formed by radially communicating with the gap of the upper outer tube 8 is opened on the side wall of the gland 2;

[0034] The cylinder body 6 is inserted into the upper outer pipe 8, and the upper end of the valve seat 5 used to fix the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com