Pipeline valve

A pipeline valve and valve body technology, which is applied in sliding valves, valve devices, engine components, etc., can solve the problems of increased production costs for enterprises and easy jamming of hard-sealed butterfly valves, so as to achieve great economic benefits, improve safety and reliability, and increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

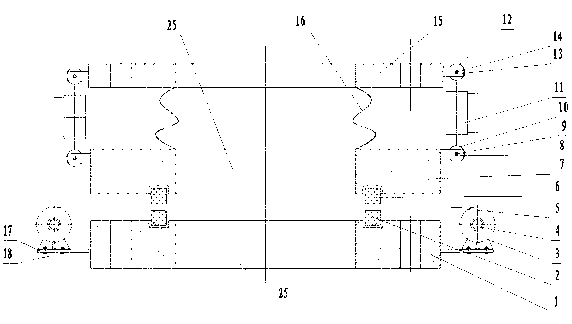

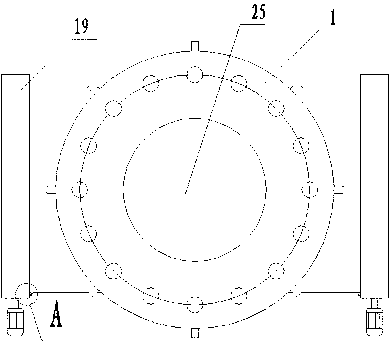

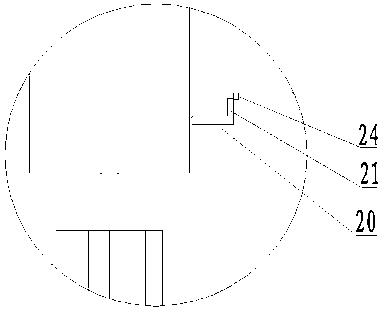

[0016] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Such as Figures 1 to 4 A pipeline valve shown includes an upper valve body 7 and a lower valve body 1, the upper valve body 1 and the lower valve body 2 are oppositely provided with valve body holes 25 of the same size, and the two sides of the lower valve body 1 are symmetrical A reel 19 is provided, a belt-shaped valve core 5 is arranged between the upper valve body 7 and the lower valve body 1, and at least two valve core holes 23 are arranged on the belt-shaped valve core 5, and between two adjacent valve core holes 23 The distance is greater than the diameter of the valve body hole 25. One side of the strip valve core 5 is provided with three protrusions 24. Connected, the bottom surface of the upper valve body 7 is provided with an upper valve body seal 6, and the top surface of the lower valve body 1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com