Automatic feed mechanism of numeric-control drill tip grinder

An automatic feeding and grinding machine technology, which is applied to the parts of boring machine/drilling machine, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of easy material jamming, and achieve the effects of improving production efficiency, fast feeding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

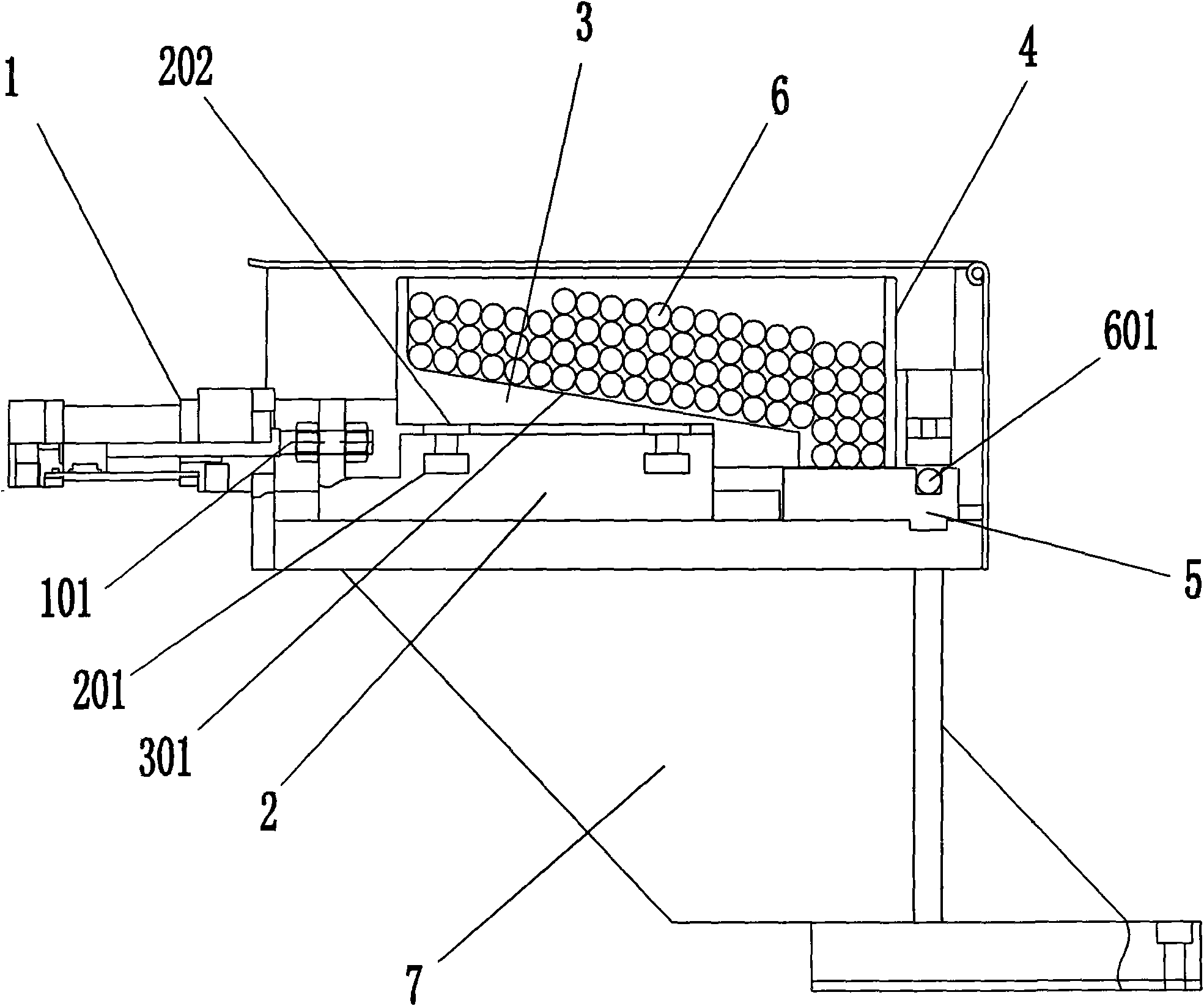

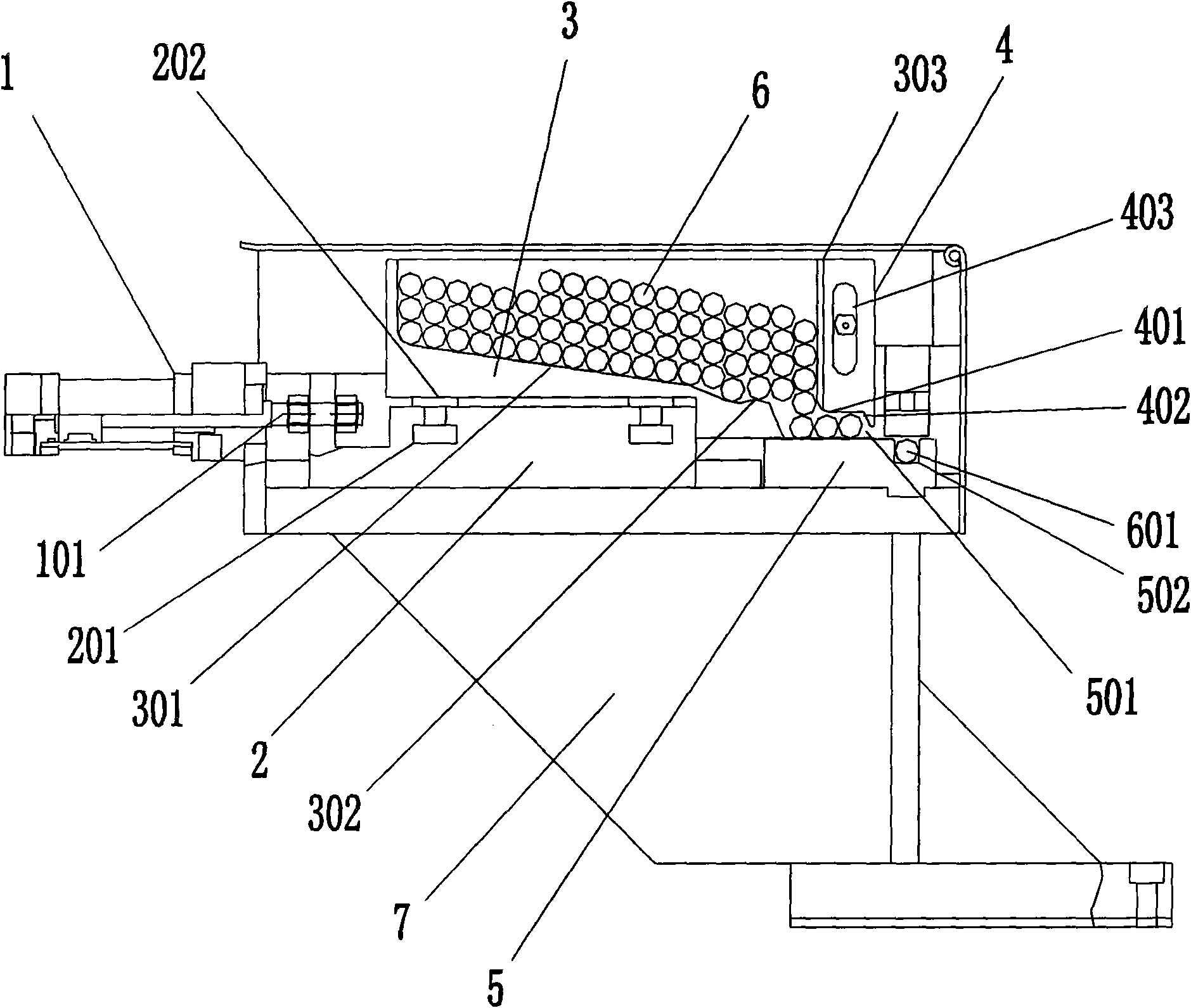

[0021] The core idea of the present invention is: there is a section of buffer arc surface at the end of the bottom surface of the silo, the drill bit can be pushed down along the buffer arc surface, and the inertia and impact during the downward process of the drill bit can be effectively reduced while pushing the guide plate through The "U"-shaped groove and screws are movably fixed on the side wall of the discharge port of the silo, and there is a notch with an inclined chamfer at the lower end of the guide plate, and the inclined chamfer gradually downwards, and forms a gap with the guide block. Open slot, when the drill bit advances, it can pass through the inclined chamfered gap smoothly through the open slot, and enter the receiving slot, so that there will be no material jamming phenomenon.

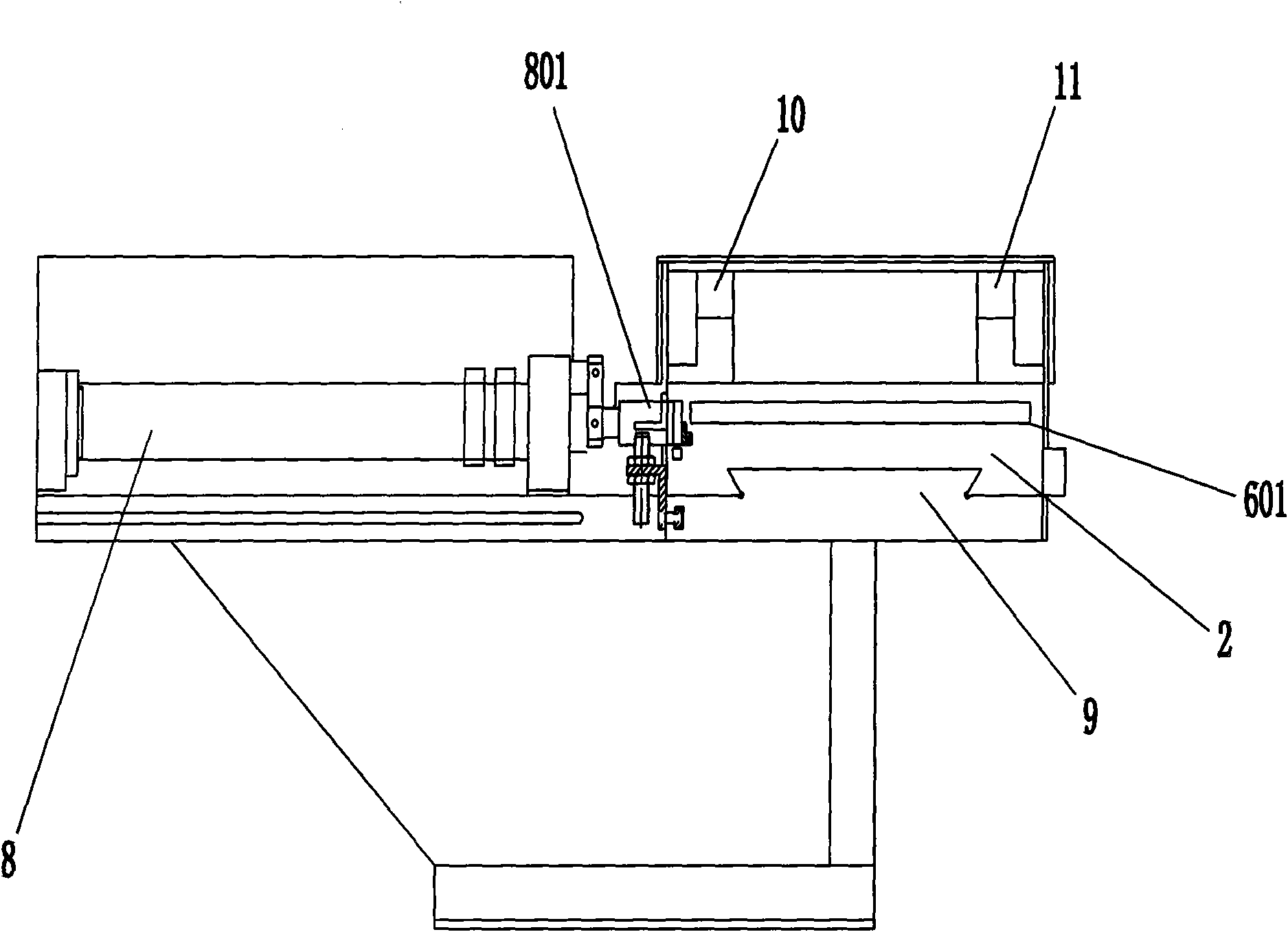

[0022] In order to illustrate the idea and purpose of the present invention, the present invention will be further described in detail below in conjunction with the accompanying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com