Patents

Literature

108results about How to "Improve feeding stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

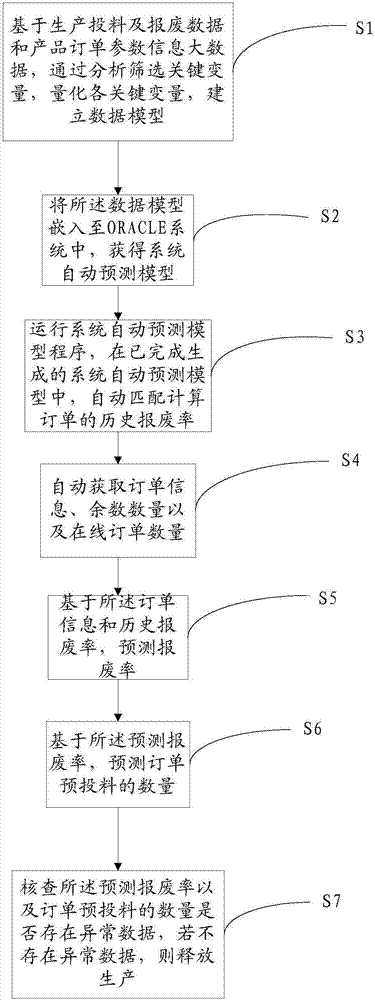

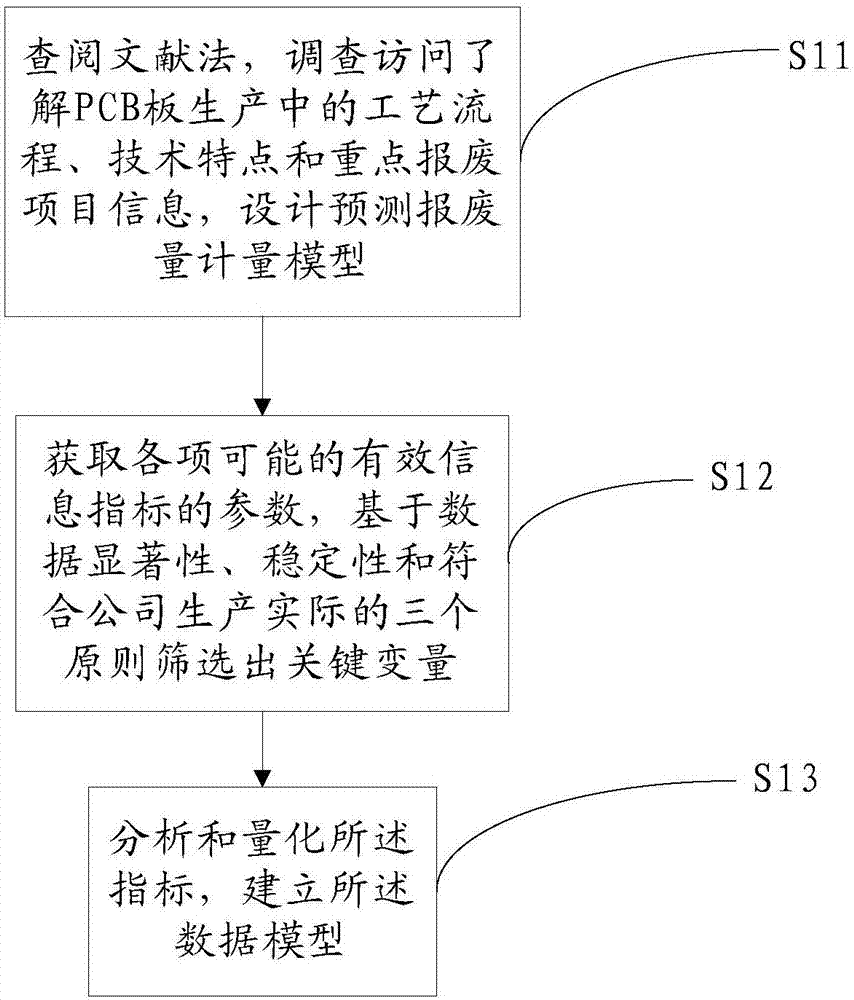

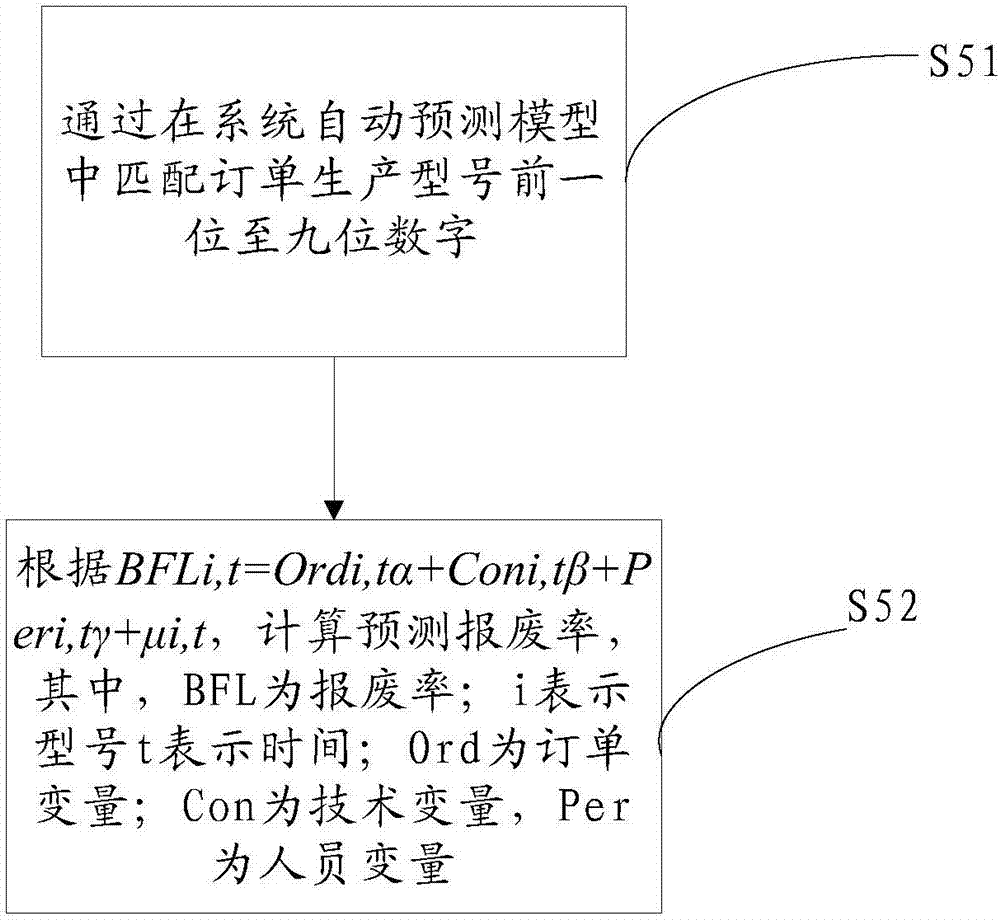

Automatic feeding method and system for multiple varieties and small batch of PCBs

ActiveCN107065795AImprove on-time deliveryIncrease production capacityTotal factory controlProgramme total factory controlProduct orderOrder form

The invention relates to an automatic feeding method and system for multiple varieties and small batch of PCBs. The method comprises the following steps of: quantifying factor variable data and establishing a data model by analyzing and selecting a key influencing factor based on production feeding, scrap data and product order parameter information big data; embedding the data model into an ORACLE system and obtaining a system automatic prediction model; running a model program, automatically matching calculating the historical scrap rate of the orders in the generated system automatic prediction model, and automatically obtaining order information, the number of remainders and the number of online orders; predicting the scrap rate based on the order information and historical scrap rate; based on the predicted scrap rate, predicting the number of pre-fed materials of the order; checking whether abnormal data exists in the predicted scrap rate and the number of pre-fed materials of the order, and releasing production if not. The method and system eliminate difference in manual feeding experience, improve feeding stability, improve production efficiency, improve accuracy and promote automatic lean production.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

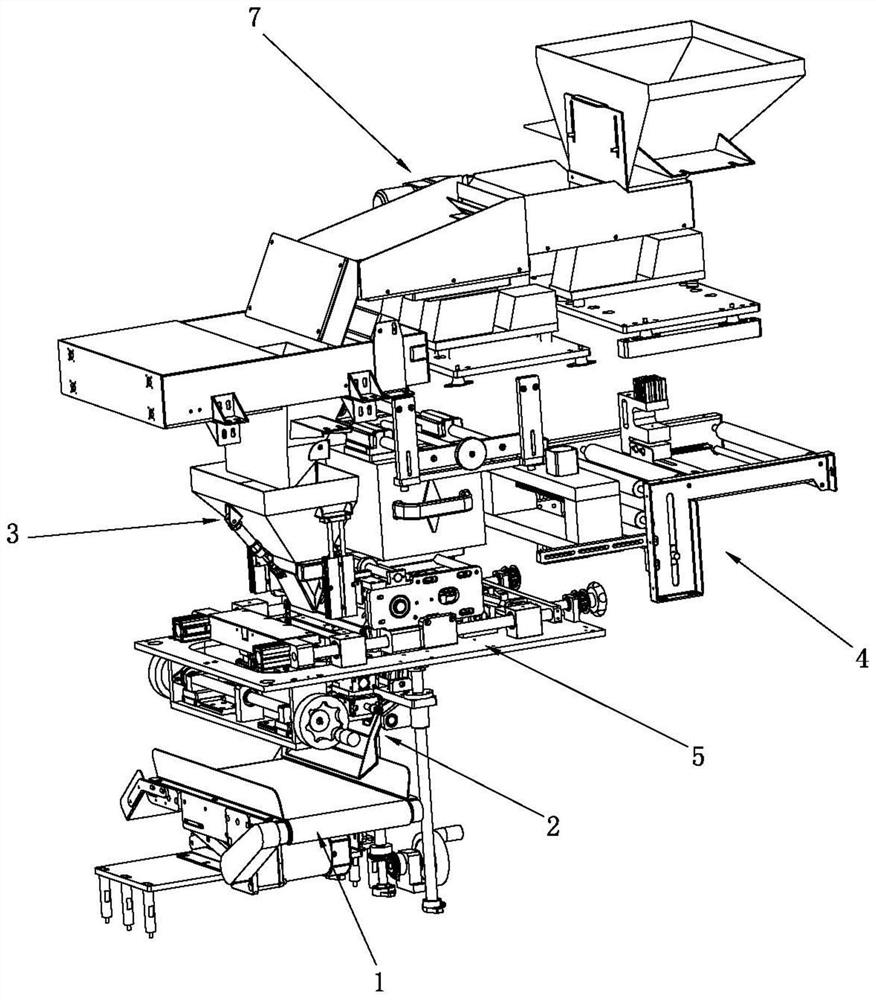

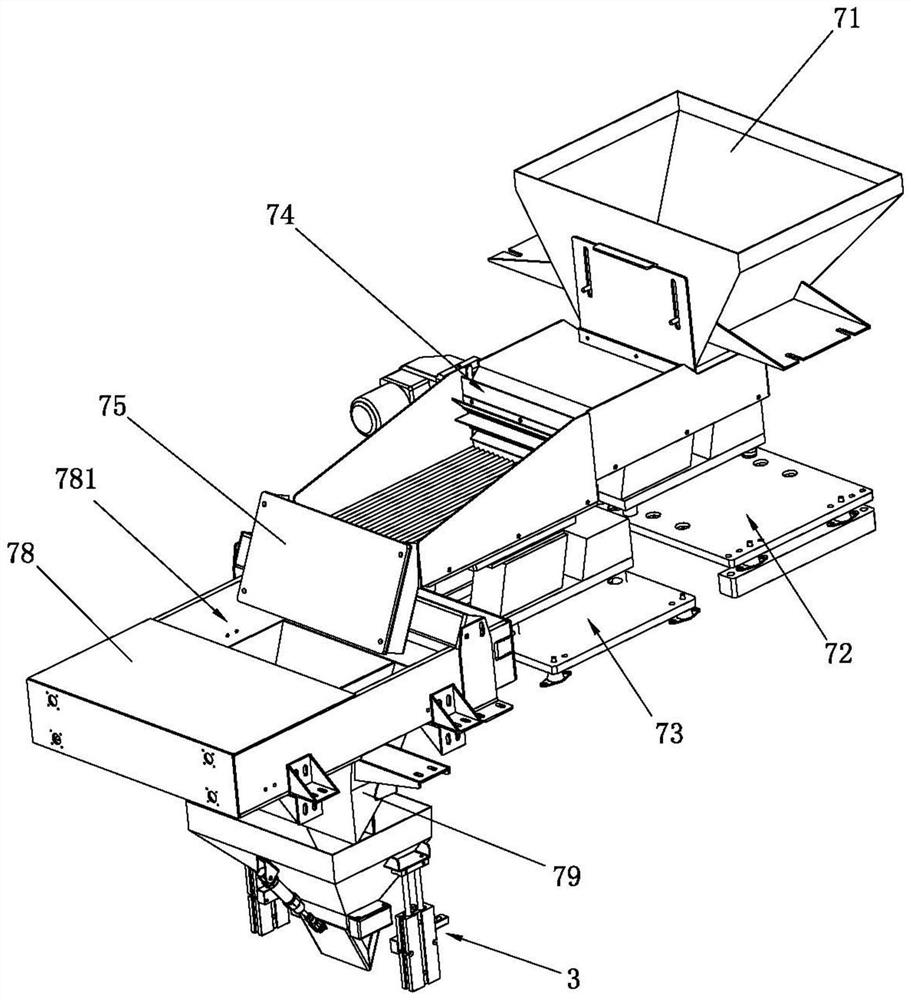

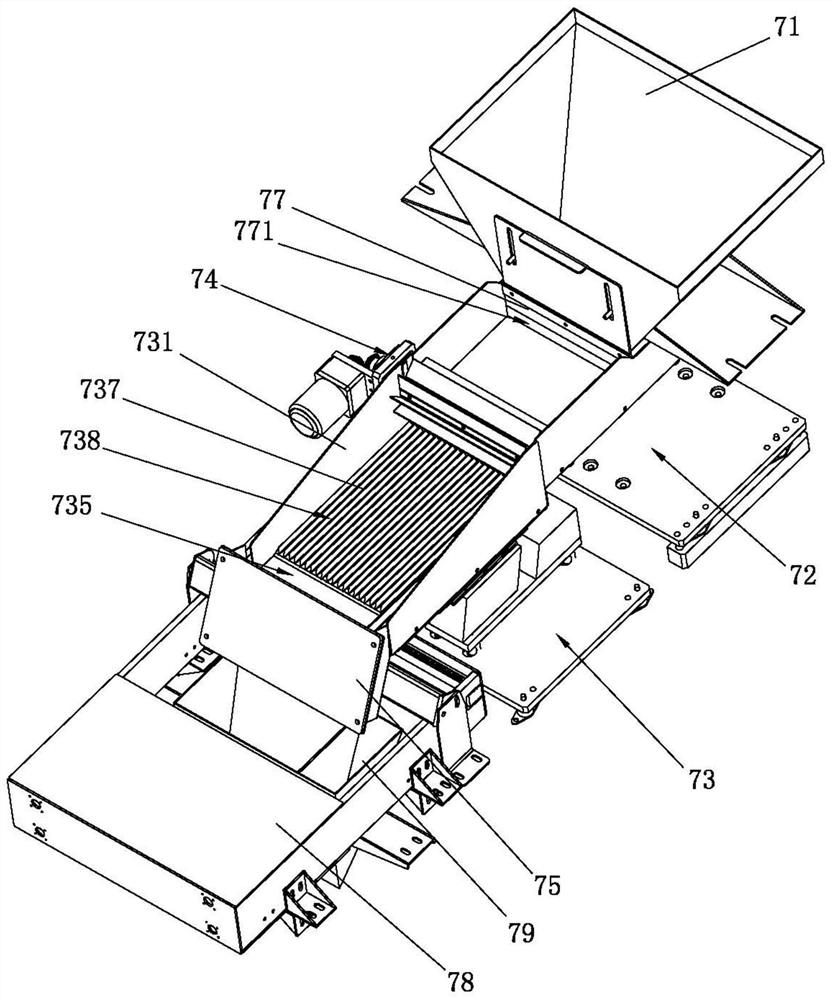

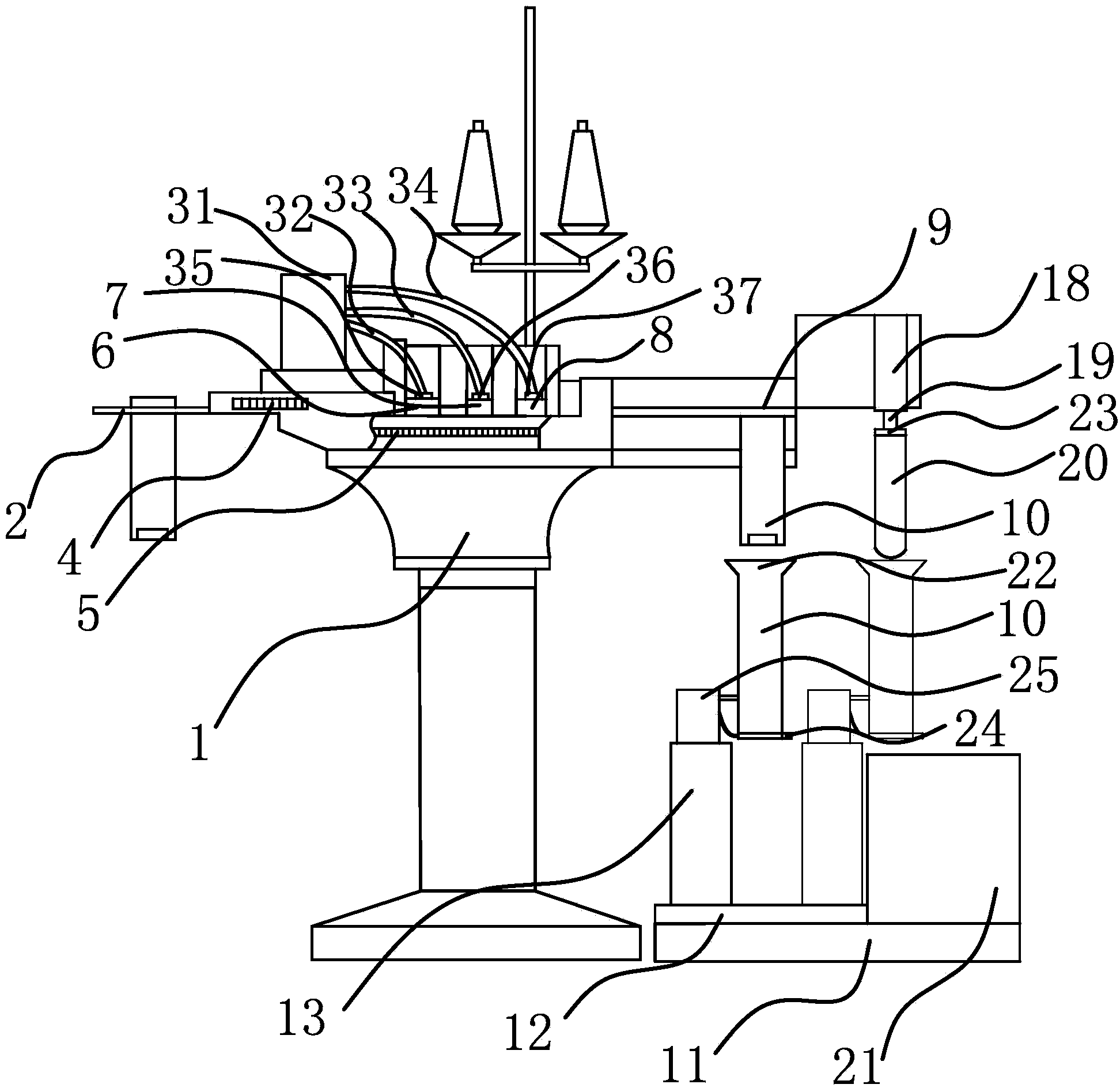

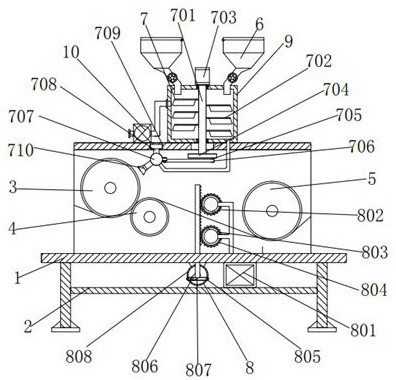

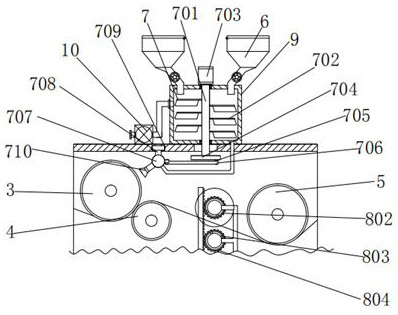

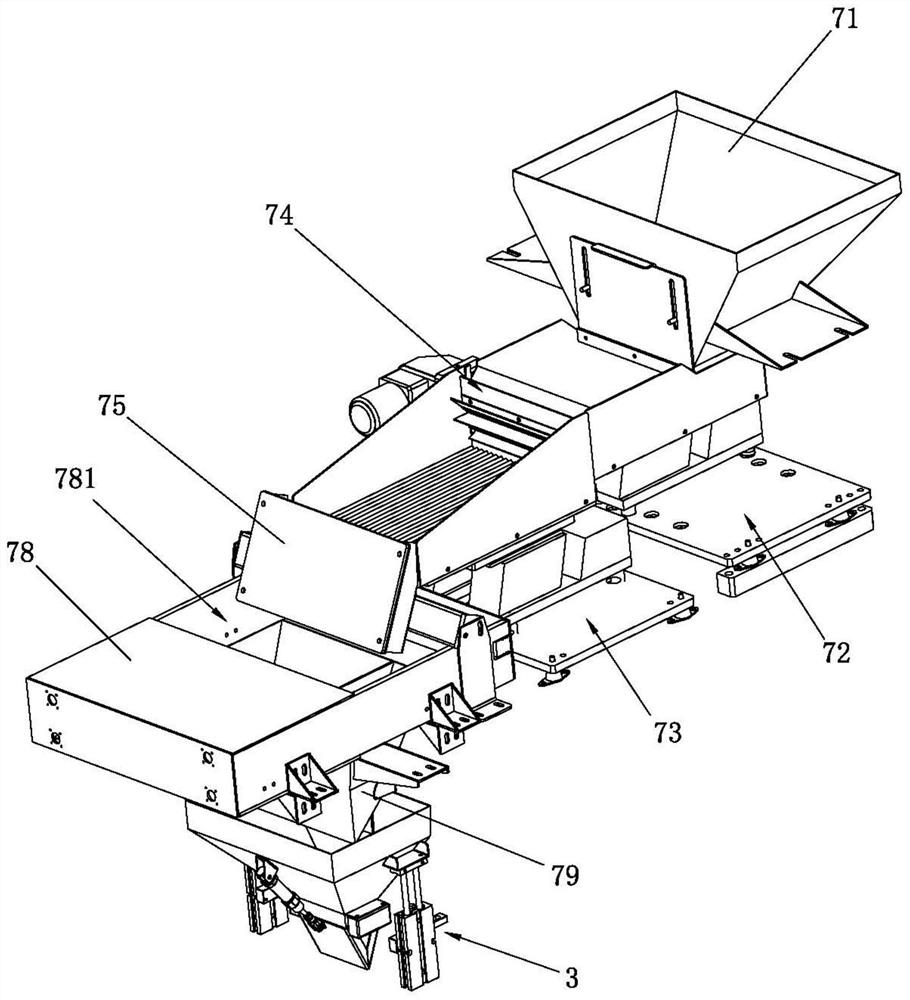

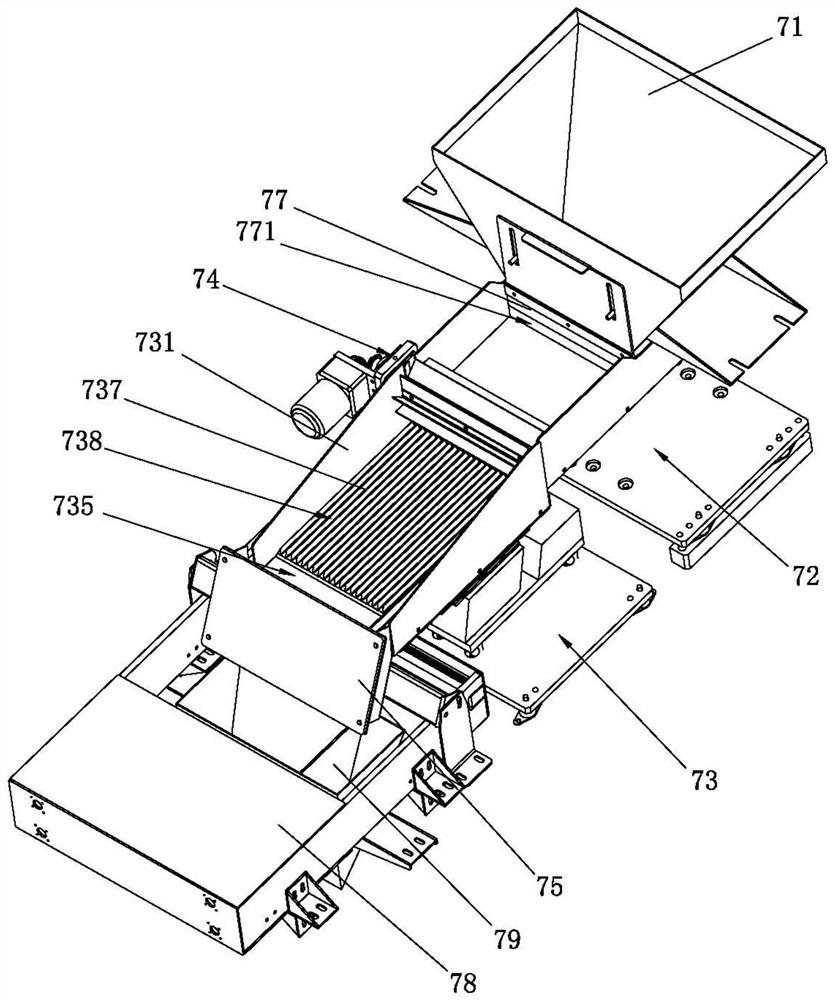

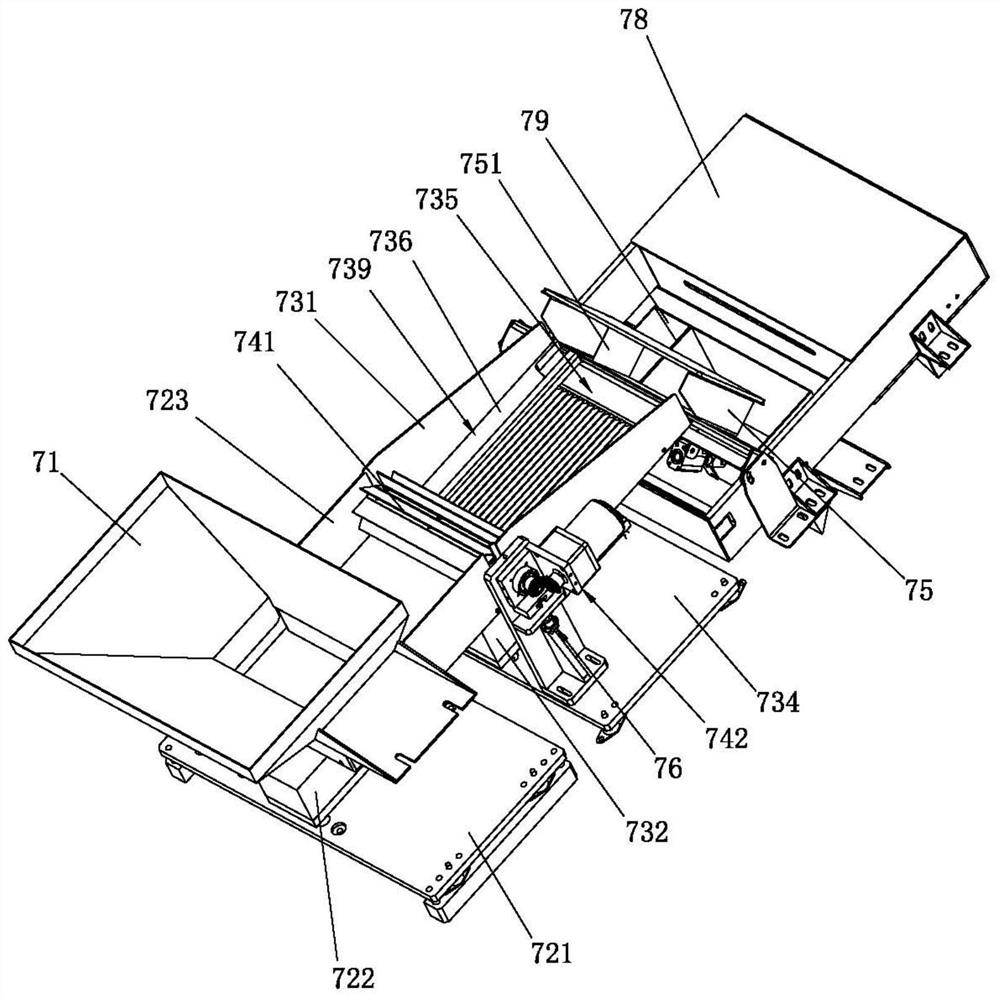

Visual counting and packaging all-in-one machine

ActiveCN112744373AEffective dispersionReduce overlapWrapping material feeding apparatusWrapper twisting/gatheringVisual CountEngineering

The invention relates to the technical field of packaging machines, in particular to a visual counting and packaging all-in-one machine comprising a machine table, a barrel film feeding device, a bag opening, cutting and sealing all-in-one device, a lower material supporting device, a bagging device and a precise feeding device. The precise feeding device comprises a feeding hopper, a first feeding mechanism, a second feeding mechanism, a flattening mechanism, a visual counting device and a quantitative hopper, a discharging port of the feeding hopper is located above the first feeding mechanism, the discharging end of the second feeding mechanism is located above the second feeding mechanism, and the quantitative hopper is located above the bagging device. The second feeding mechanism is provided with a rapid material channel and a fine supplementing material channel, the visual counting device is located below the second feeding mechanism, and the quantitative funnel is exposed out of the visual counting device. The quantitative bagging and packaging of materials are automatically achieved, double-channel feeding is achieved, the feeding efficiency is high, the materials can be effectively dispersed, the materials are made to move flatly, the number of the materials is accurately calculated, and the packaging quality of the materials is improved.

Owner:东莞市安翔智能包装设备有限公司

Metal powder injection molding feedstock and preparation method thereof

InactiveCN108672695AImprove liquidityImprove wettabilityTransportation and packagingMetal-working apparatusMicrocrystalline waxHigh density

The invention discloses a metal powder injection molding feedstock and a preparation method thereof. The feedstock comprises a forming agent and stainless steel feedstock powder, wherein the forming agent comprises, by weight percentage, 65-72% of POM, 2-4% of microcrystalline wax, 3-6% of polyvinyl alcohol, 8-12% of POE, 1-3% of a photo-thermal stabilizer, 10-12% of high density ethylene and 4-6%of polypropylene; and the mass ratio of the forming agent to the stainless steel feedstock powder is 7-9 to 91-93. By the adoption of the feedstock, the product which is obtained through the metal powder injection molding process has obviously improved bending resistance, anti-falling mechanical property and anti-wear mechanical property, and meanwhile, the high-quality appearance surface effectcan also be achieved.

Owner:DONGGUAN HUAJING POWDER METALLURGY

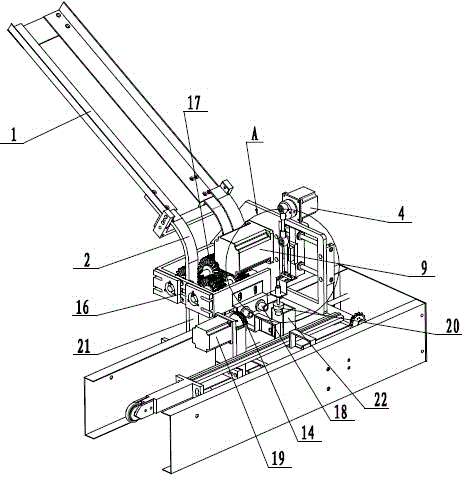

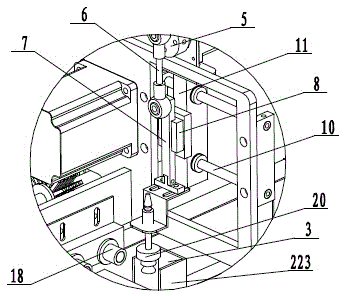

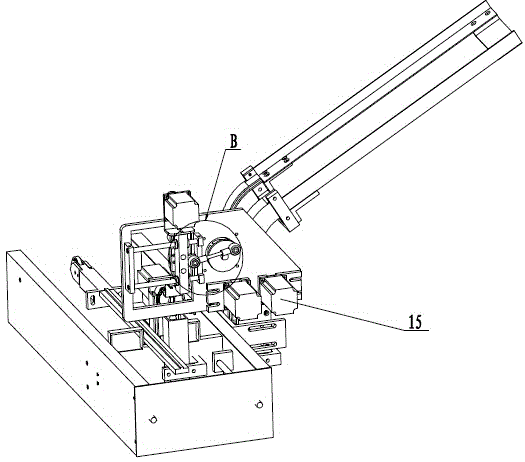

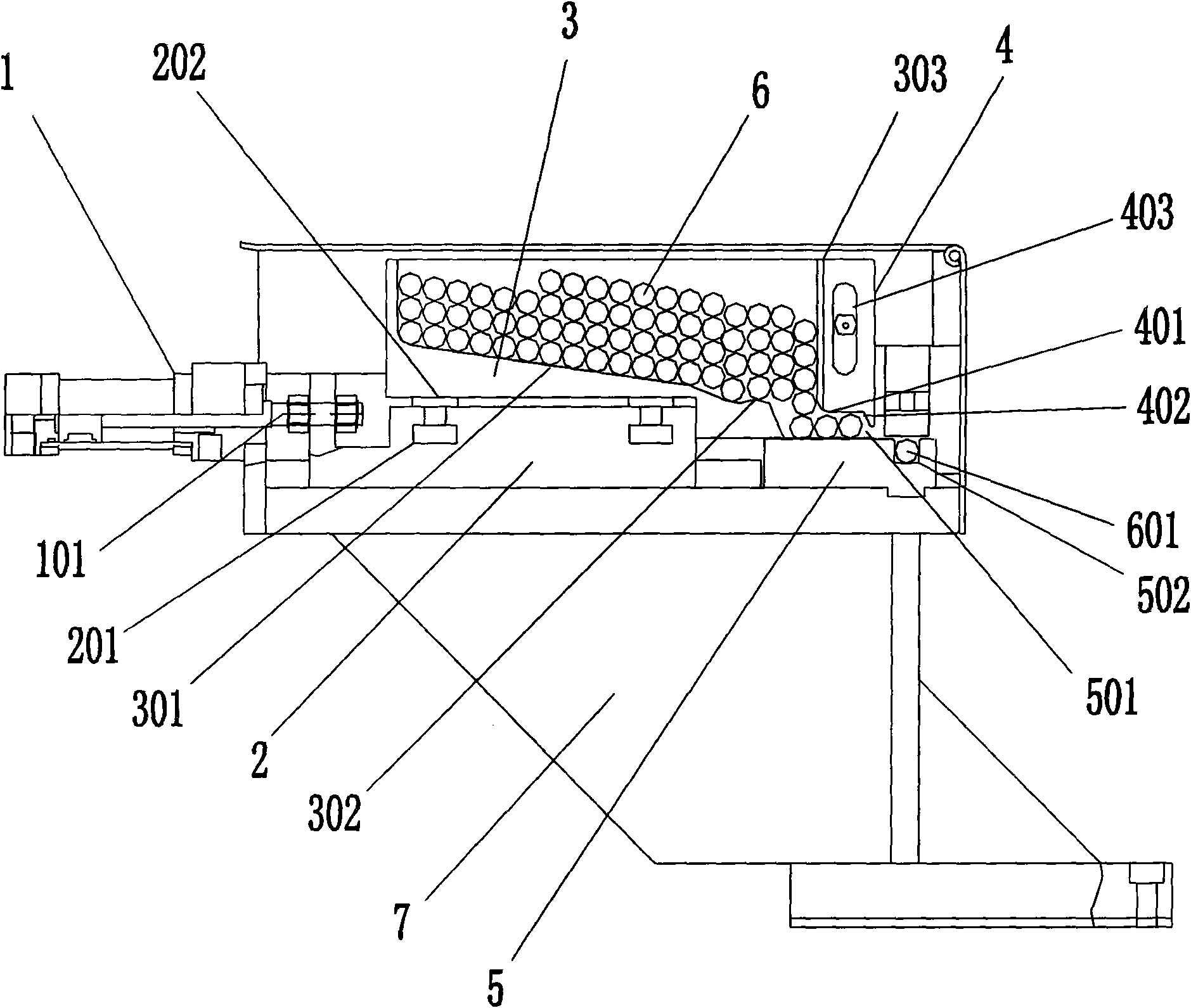

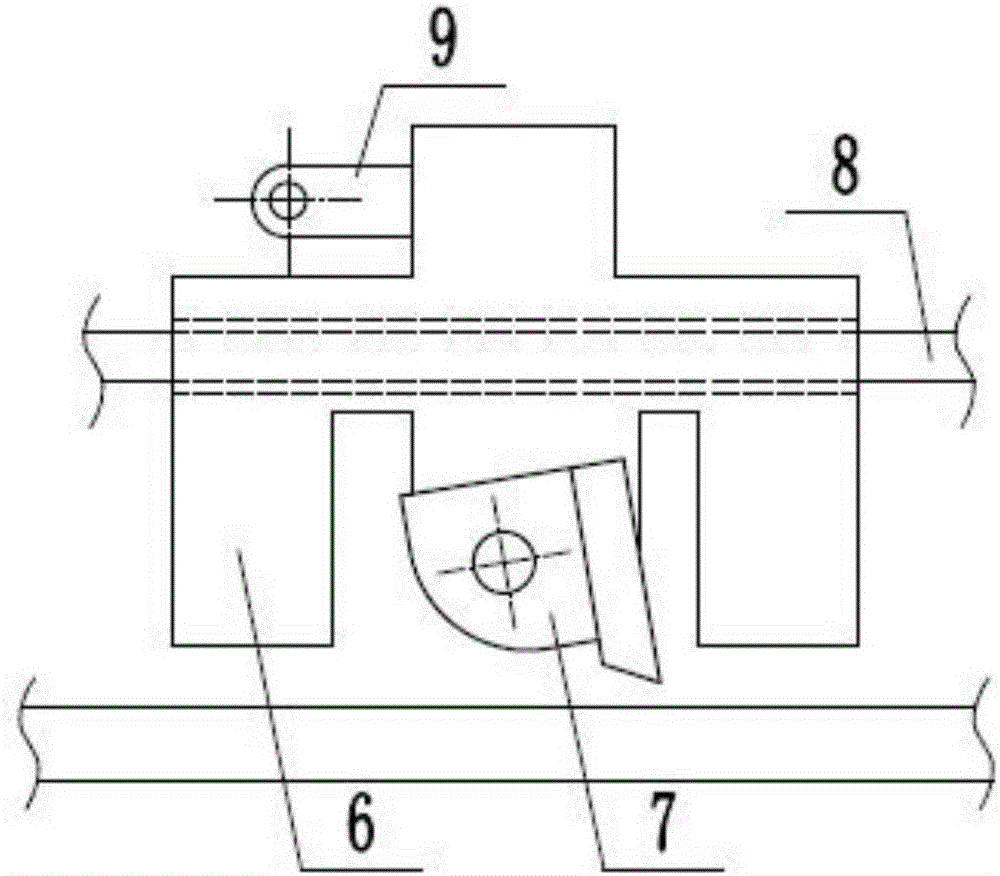

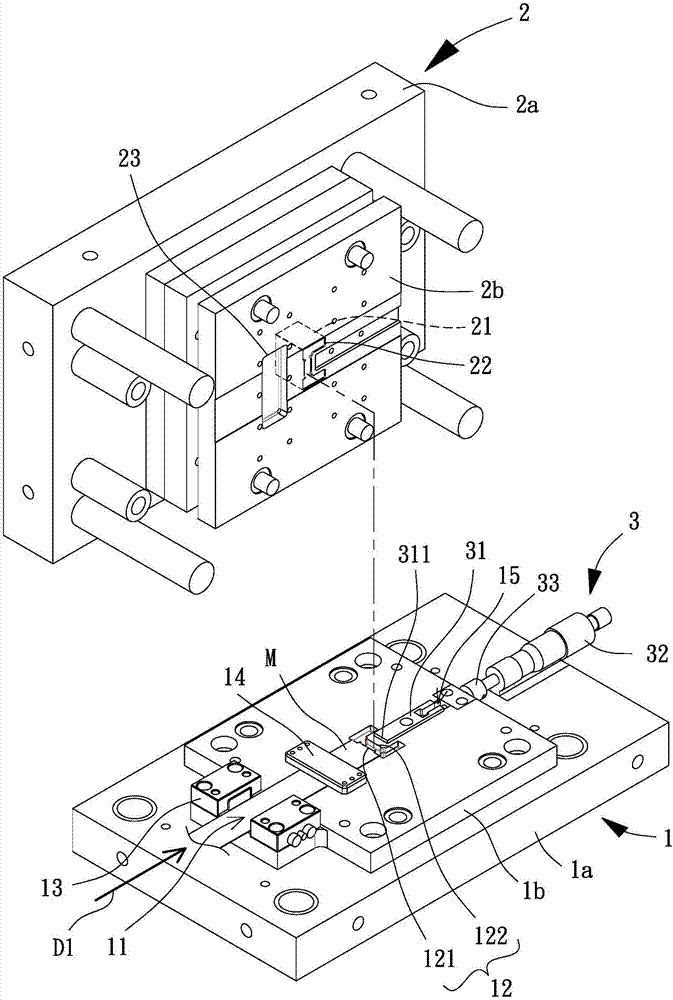

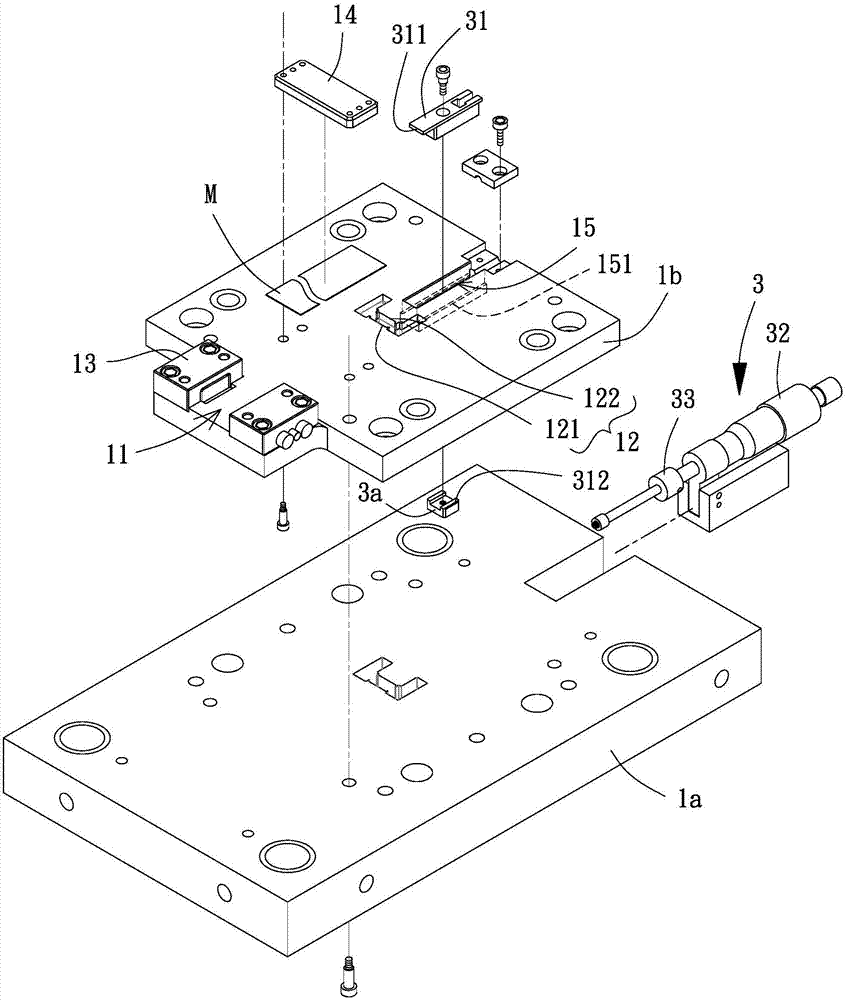

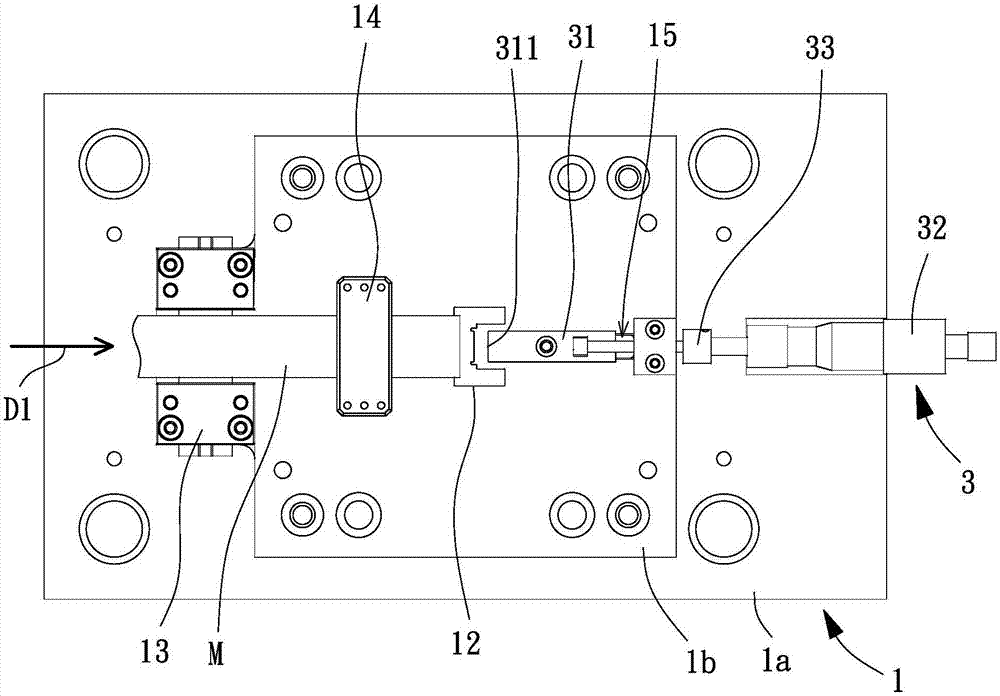

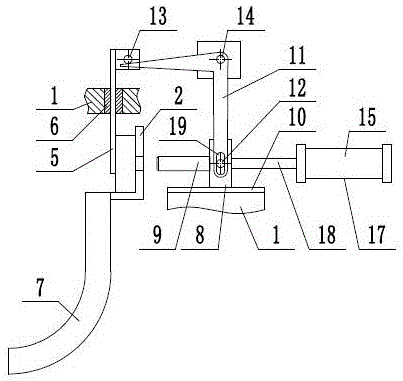

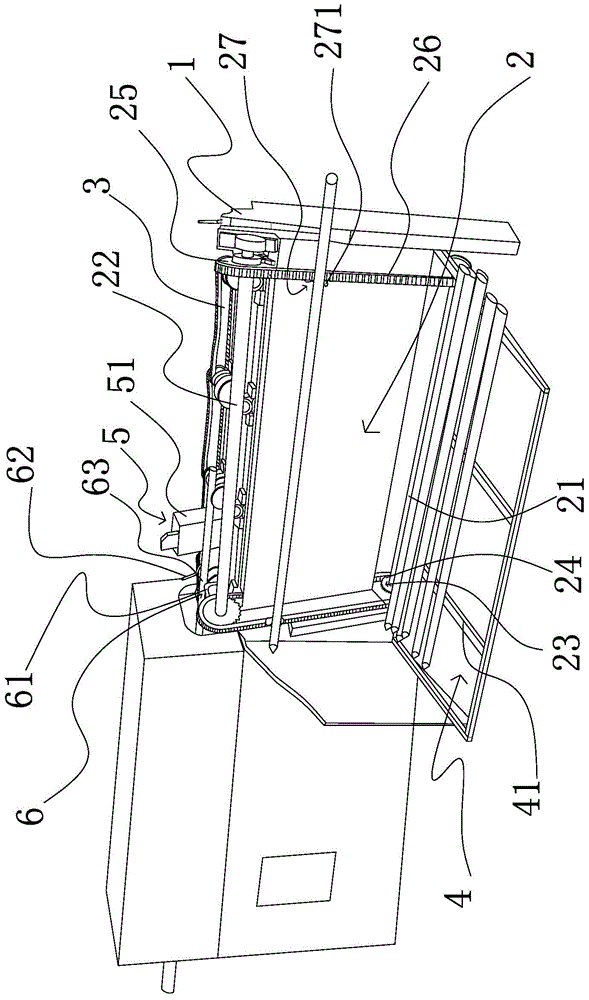

Unloading device of knife, fork and scoop packing machine

ActiveCN104670554AAvoid falling simultaneouslyImprove feeding stabilityPackaging automatic controlButt jointIndustrial engineering

The invention relates to an unloading device of a knife, fork and scoop packing machine, which mainly solves the problems of the existing catering tool that multiple materials are unloaded and the package is affected when in unloading. The unloading device comprises a discharge guide rail, an unloading guide rail, a feeding mechanism and a conveying mechanism, wherein the discharge guide rail is used for storing a material, the unloading guide rail is connected with the discharge guide rail, the feeding mechanism is used for pushing the material to be fed along the unloading guide rail, the unloading guide rail comprises an arc transitional part and a guide part, the guide part is in a U shape and comprises a first vertical part, an arc curved part and a second vertical part, the arc transitional part is in butt joint with the discharge guide rail, the bottom of the curved part is connected with the first vertical part and the second vertical part, the first vertical part is in abut joint with the arc transitional part, and an opening is formed in the end part of the second vertical part. By adopting an unloading-after-loading continuous unloading way, the affection of the gravity and an acting force between two adjacent materials can be avoided, the phenomenon that multiple materials are simultaneously dropped can be effectively avoided, stability in unloading is realized, and the structure is reasonable.

Owner:PINGYANG HAIHANG MACHINERY

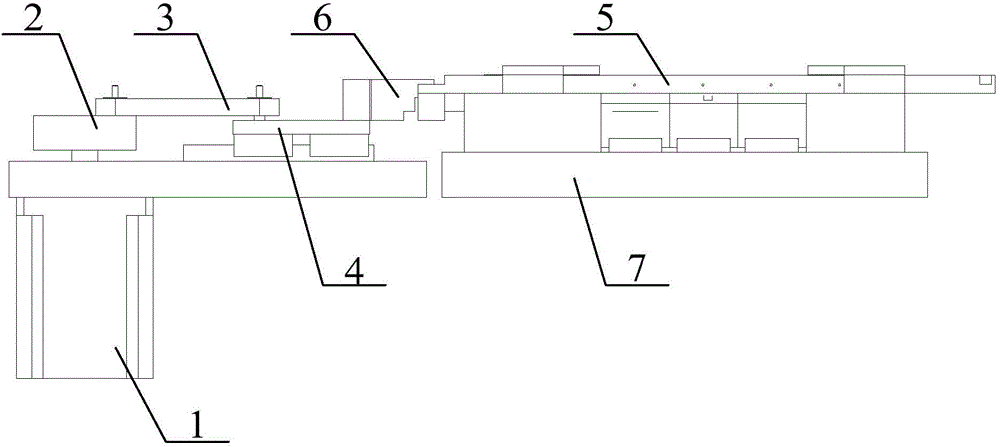

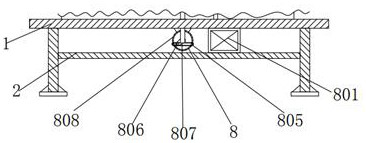

Furnace rear cover disassembling machine

PendingCN112059348AHigh degree of automationReduce manual operationsSoldering auxillary devicesAssembly lineIndustrial engineering

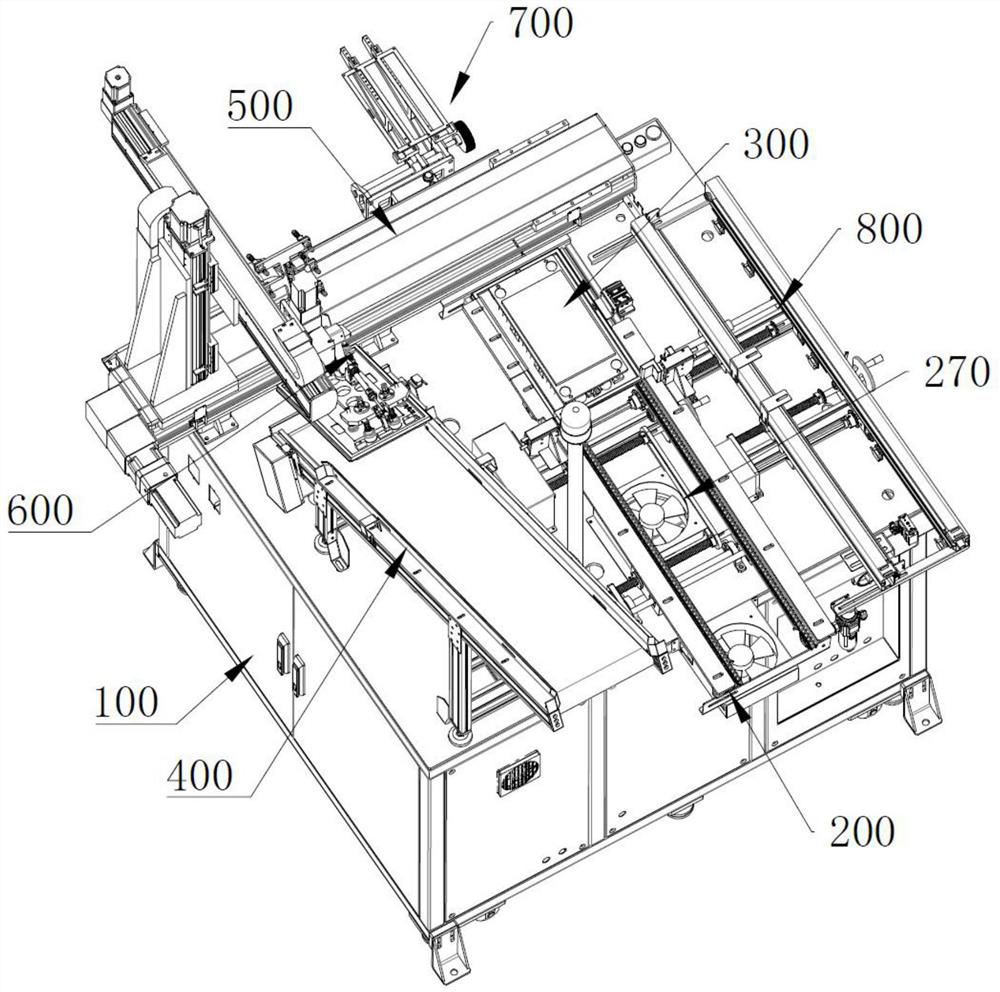

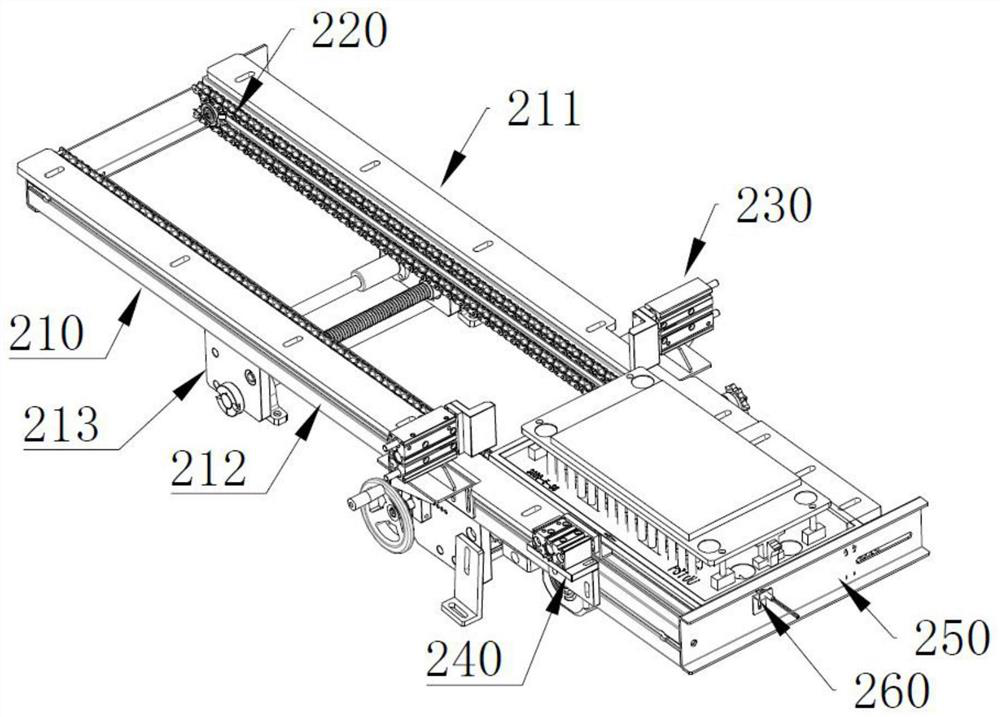

The invention relates to the technical field of automatic cover disassembling, and particularly relates to a furnace rear cover disassembling machine. The furnace rear cover disassembling machine comprises a rack, a feeding conveying device installed on the rack, a jig device installed to the feeding conveying device, a backflow device installed on the rack and located on one side of the feeding conveying device, a transmission device installed on the rack, a material taking device installed on the transmission device and a material receiving device installed on the rack and located on one side of the transmission device, wherein the transmission device drives the material taking device to be in transmission with the feeding conveying device and the backflow device. According to the furnace rear cover disassembling machine, an automatic cover disassembling structure is adopted, a jig is positioned after backflow, the transmission device drives the material taking device to be in transmission with the jig position to disassemble an upper cover of the jig after positioning, a product piece can be taken out and placed on the material receiving device after disassembling, the upper cover of the jig and a jig base are taken by the material taking structure and then are placed to the backflow device for backflow, the overall automation degree is high, manual operation is saved, and continuous work in an assembly line manner can be achieved.

Owner:东莞松山智能机器人有限公司

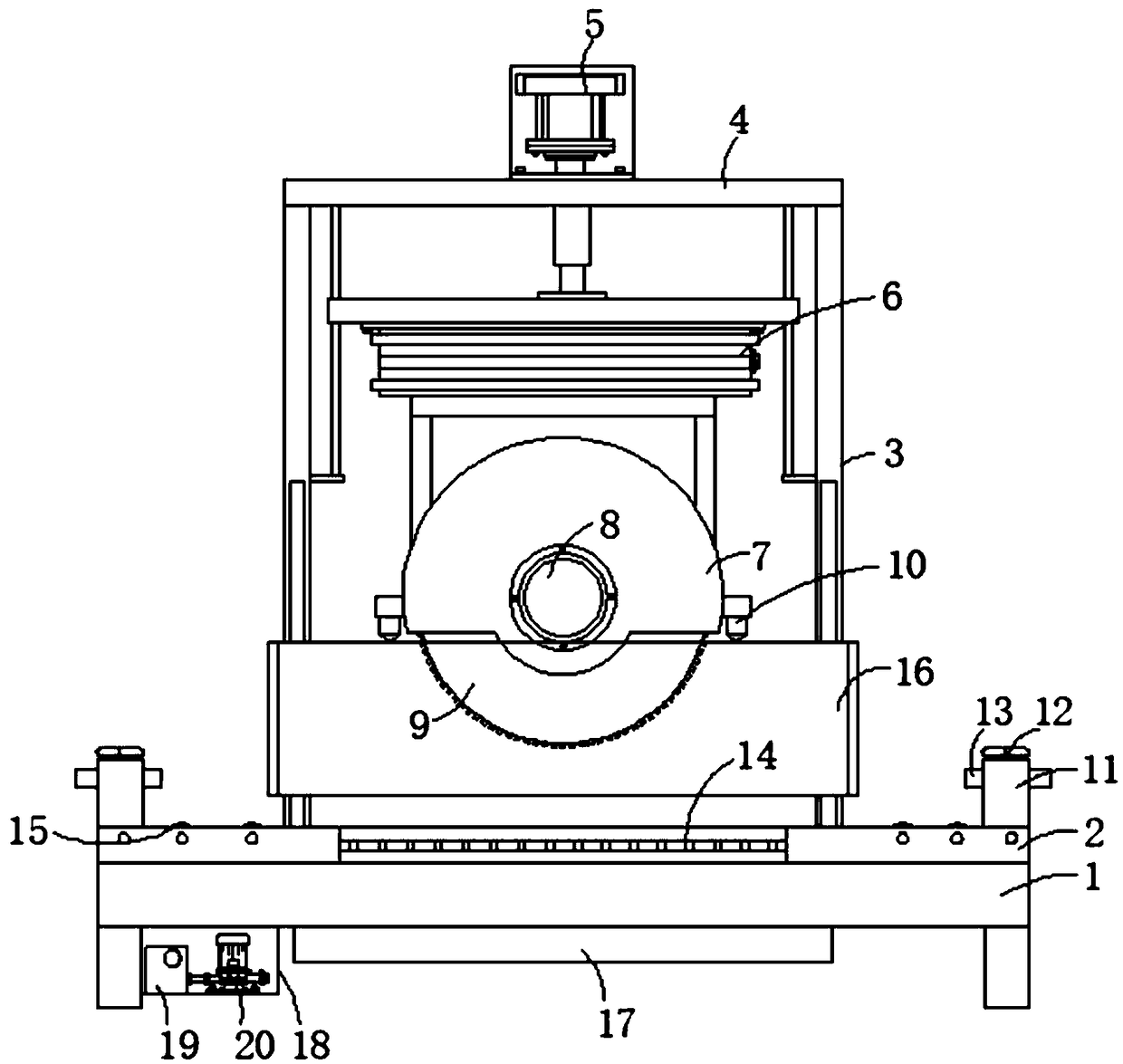

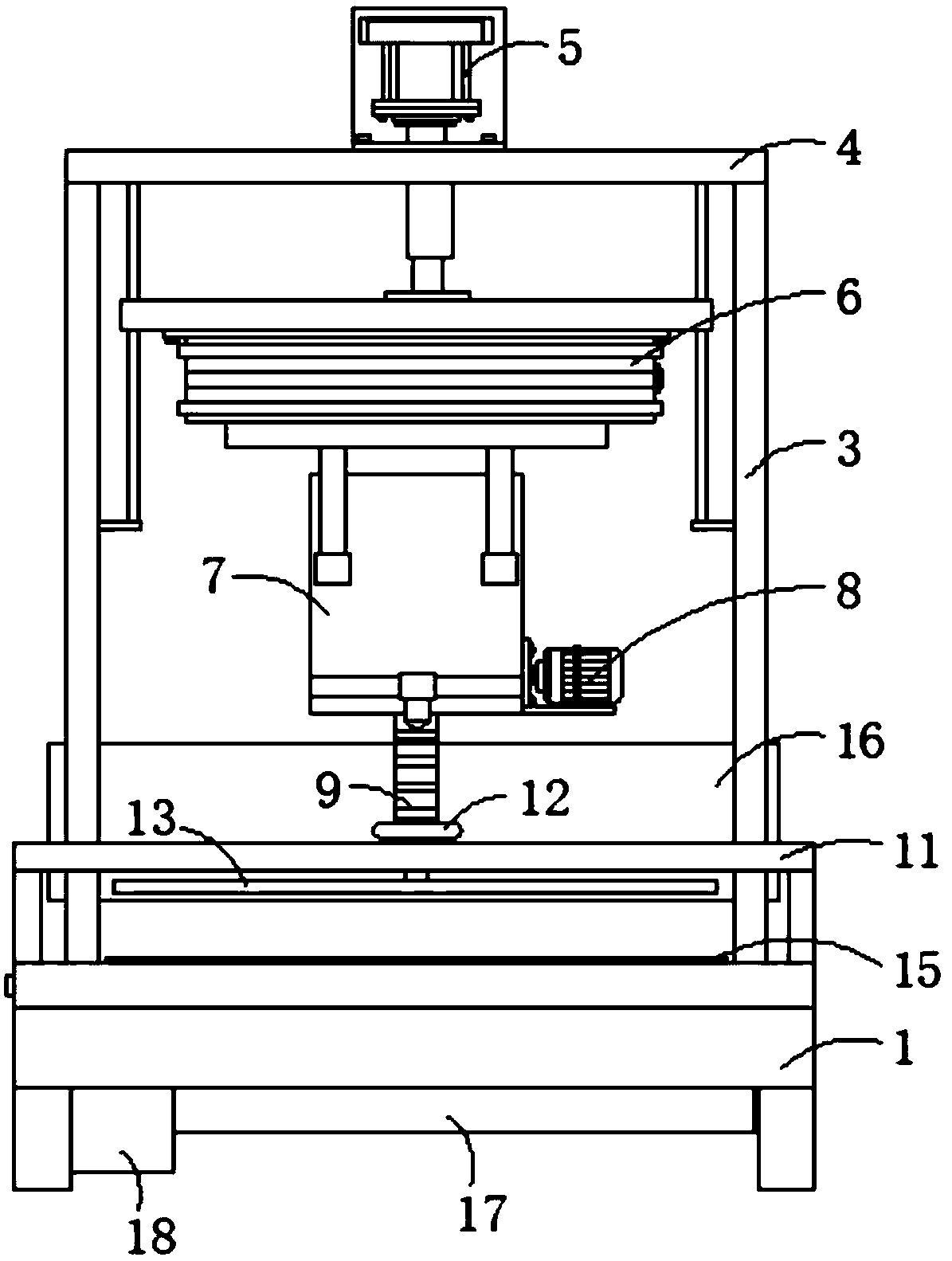

Accurate machining device of aluminum alloy plate

InactiveCN108620658AImprove cutting efficiencyIncrease profitShearing machinesShearing machine accessoriesHydraulic cylinderEngineering

The invention discloses an accurate machining device of an aluminum alloy plate. The device comprises a base, the top of the base is provided with a working platform, a supporting rod is welded to thetop of the working platform, a top plate is welded to the top end of the supporting rod, a hydraulic cylinder is fixedly connected to the top of the top plate through a bolt, one end of the hydrauliccylinder is connected with a rotary air cylinder through a hydraulic rod, the bottom of the rotary air cylinder is fixedly connected with an outer cover through a bolt, the outer wall of one side ofthe outer cover is provided with a laser lamp, a supporting frame is welded to the side, close to the supporting rod, of the top of the working platform, a thread hand rod is spirally connected to thetop of the supporting frame through a thread, and the bottom end of the thread hand rod is provided with a lifting plate. On one hand, the cut angle and length can be adjusted according to machiningrequirements, and the cutting efficiency of the aluminum alloy plate is improved; and on the other hand, the utilization rate of the aluminum alloy plate can be improved to the largest degree throughrotating angle cutting.

Owner:长兴宇通机械厂

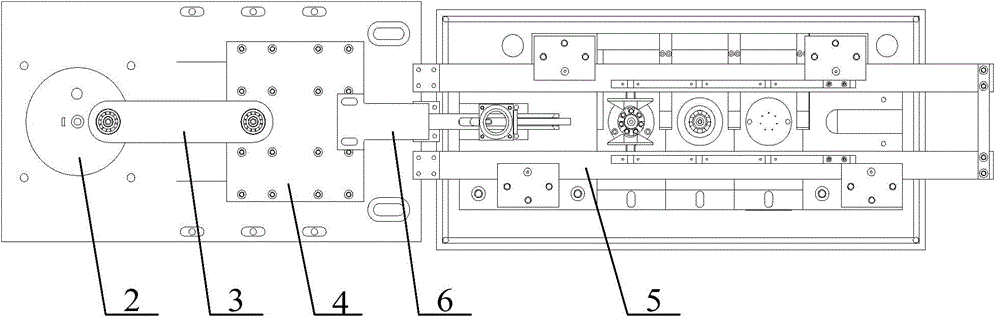

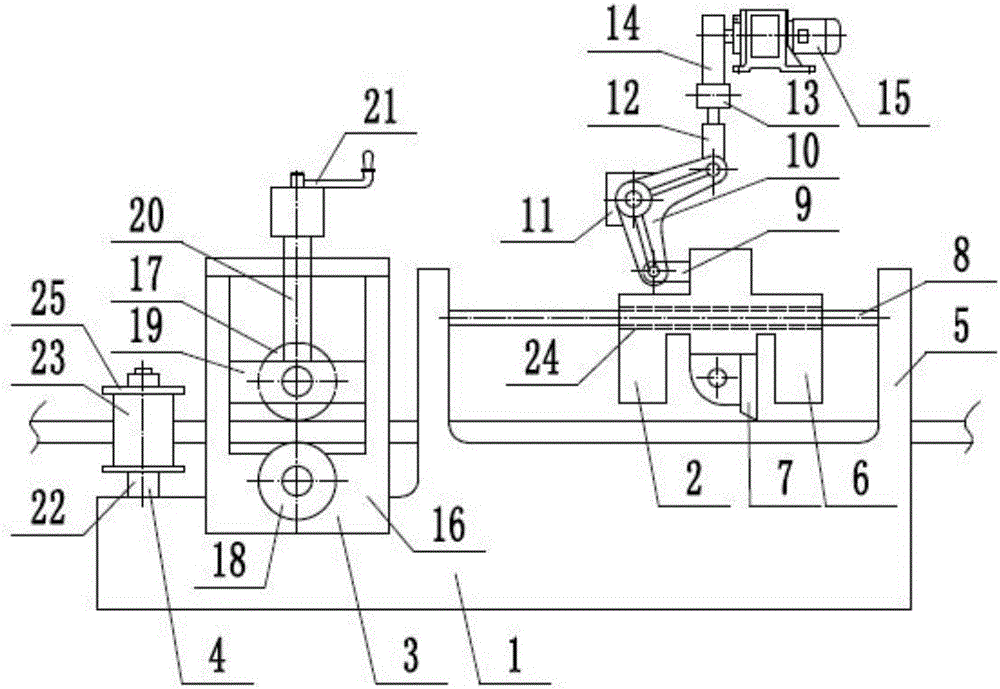

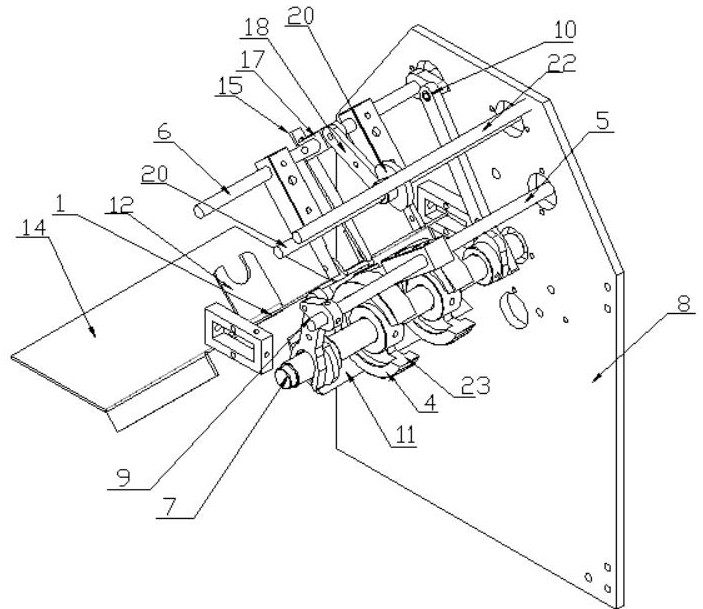

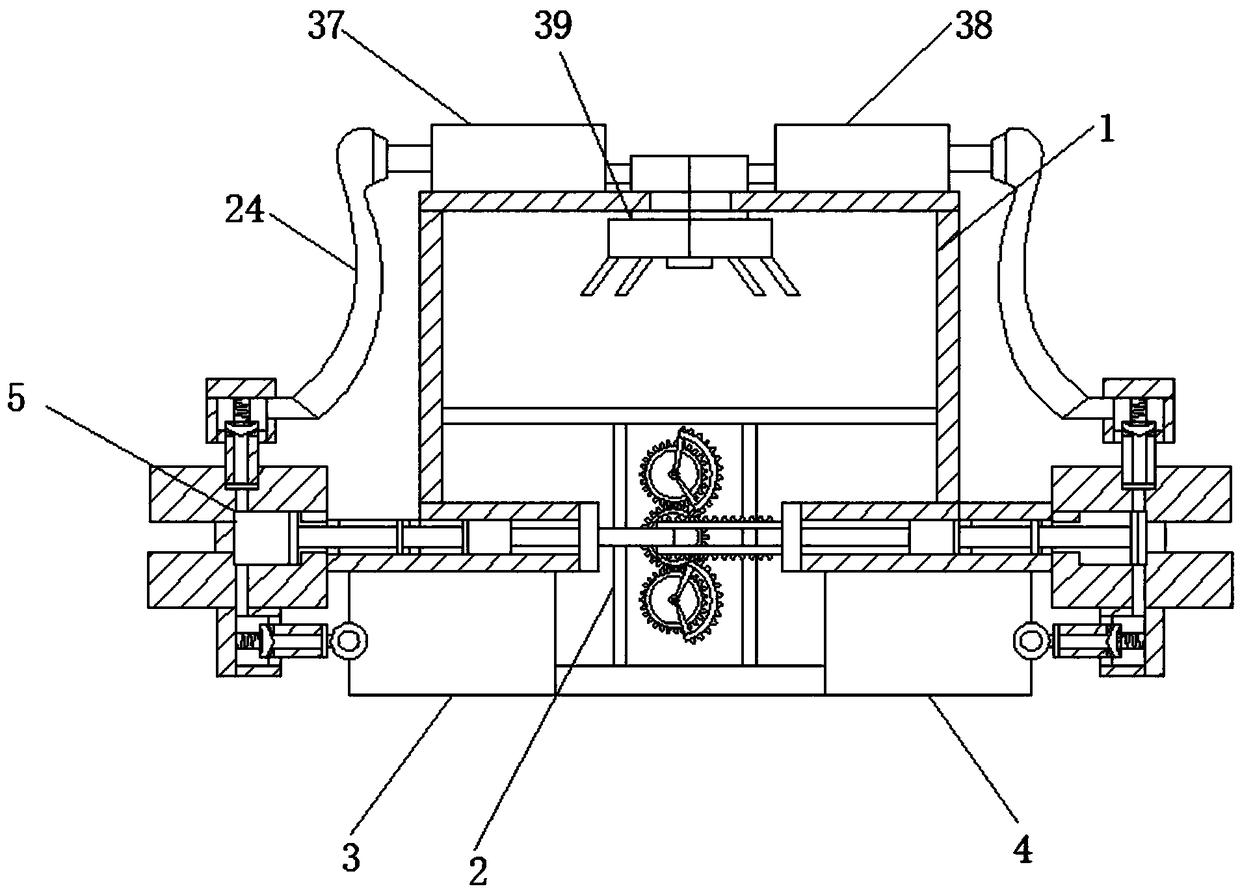

Multi-station punching machine, feeding assembly and feeding method

InactiveCN104624832AImprove stabilityGuaranteed stabilityMetal-working feeding devicesPositioning devicesPunch pressElectric machinery

The invention relates to a feeding assembly which is used for a multi-station punching machine. The feeding assembly comprises a rack, a servo motor, an eccentric wheel, a connection rod, a slide block and slide strips, wherein the servo motor is fixedly connected with the rack; the center of the eccentric wheel is fixedly connected with an output shaft of the servo motor; one end of the connection rod is hinged with the output end of the eccentric wheel; the slide block is hinged with the other end of the connection rod and is slidingly mounted on the rack; the slide strips are distributed on the two sides of a punching station, are fixedly connected with the slide block and are provided with mechanical arms. The feeding assembly is not influenced by a bottom dead center of a punching machine bent axle so that the vibration in a feeding process is avoided and the feeding stability is improved; compared with the prior art, the rotation process of the servo motor is more stable so that the feedings speed can be properly improved under the precondition that the rotation process is matched with a punching beat, and furthermore, the feeding efficiency is improved. The invention further discloses a multi-station punching machine with the feeding assembly and a feeding method applied to the feeding assembly.

Owner:聊城市润达轴承保持器厂

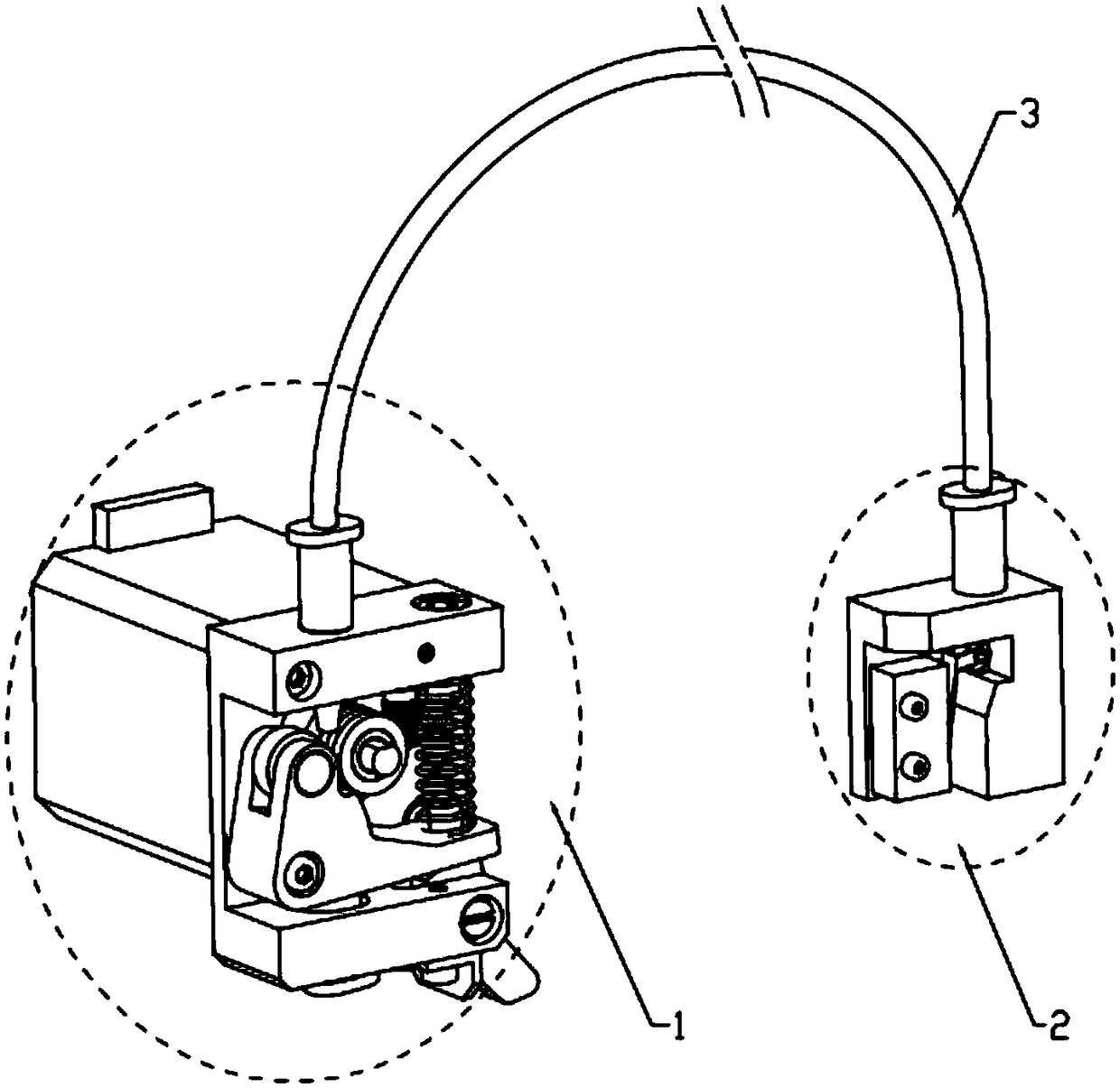

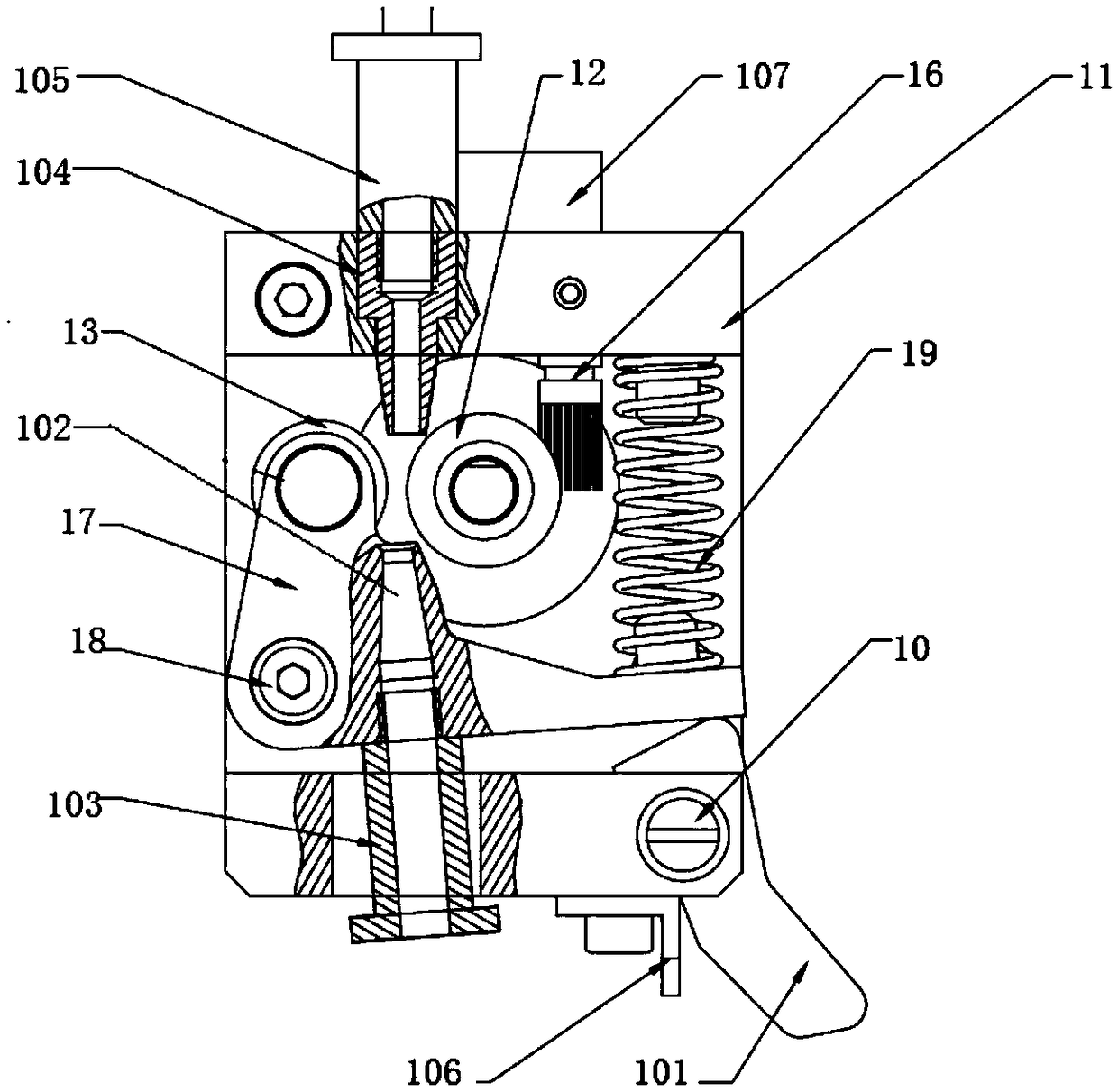

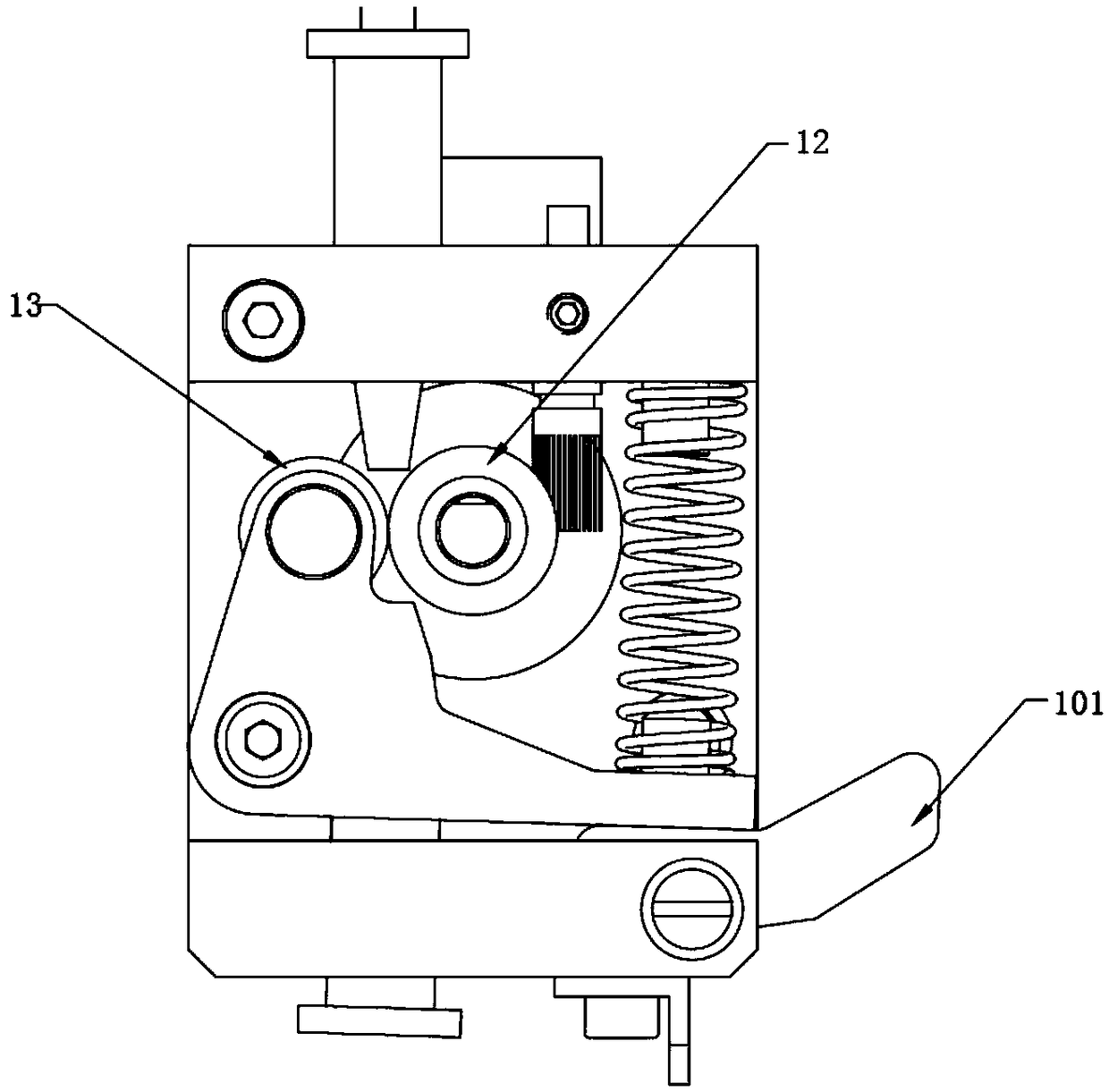

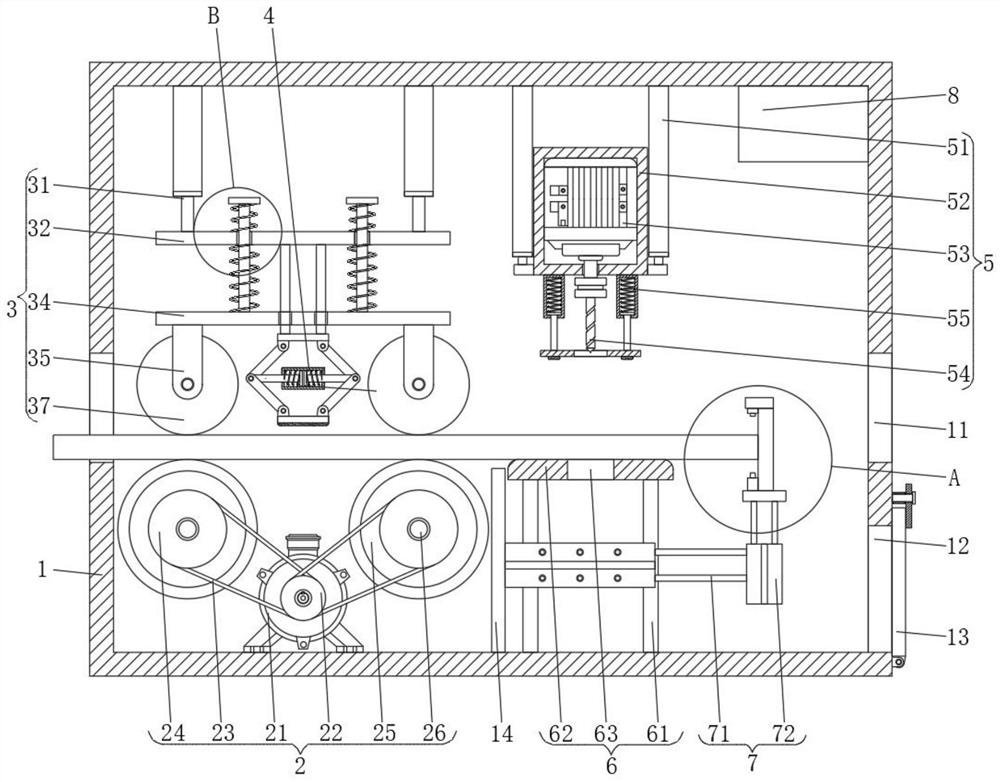

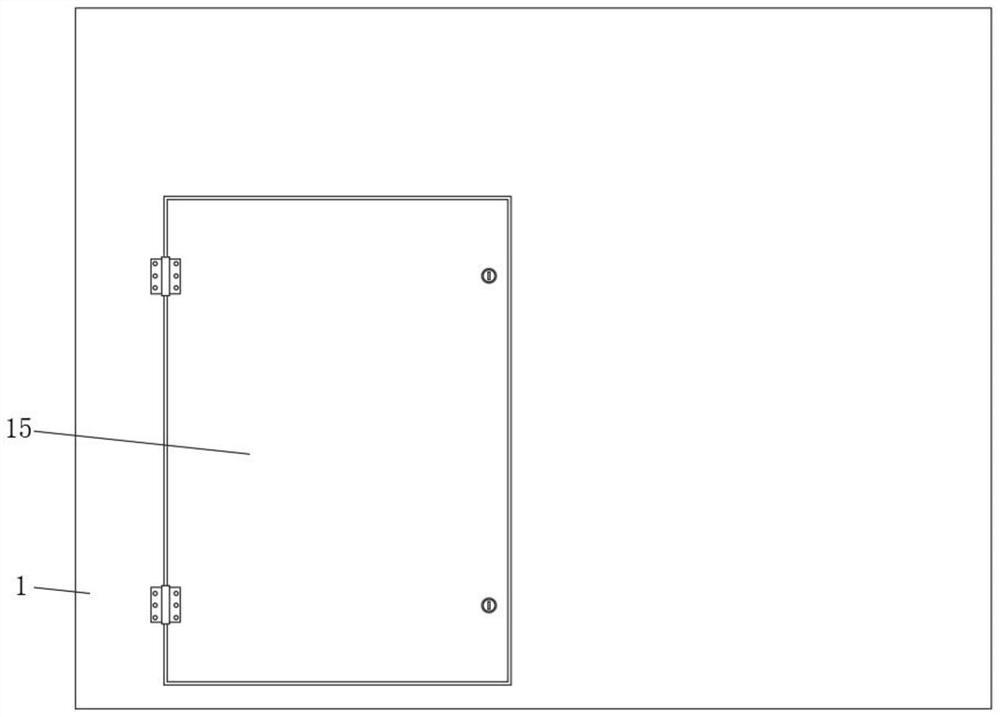

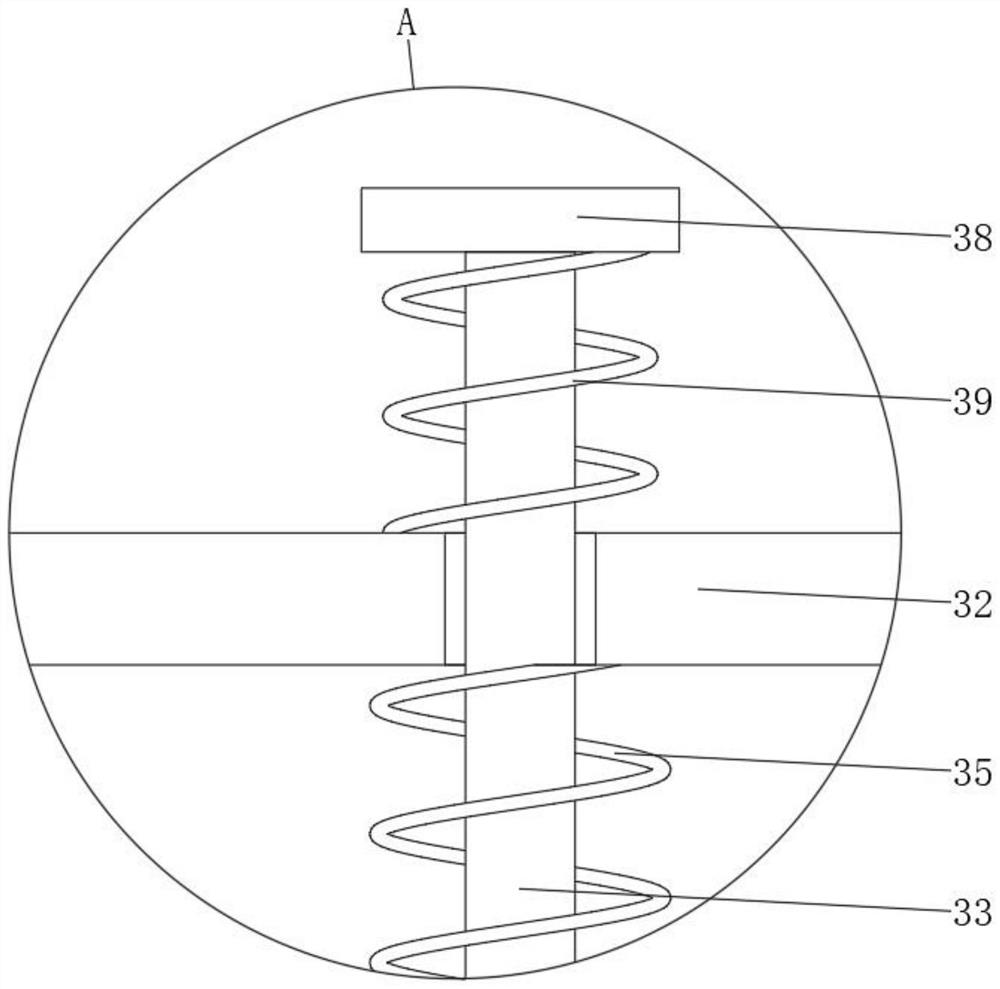

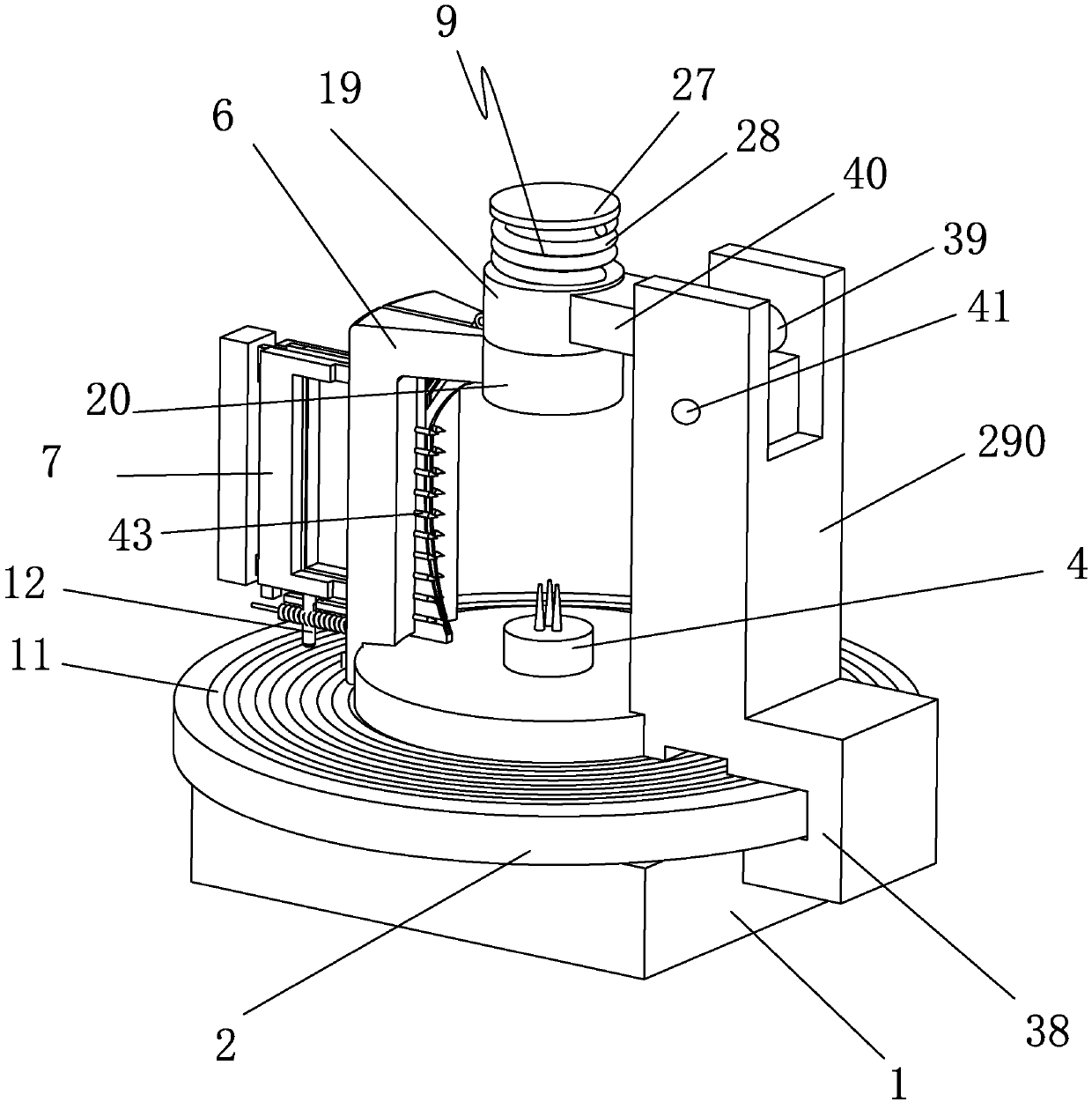

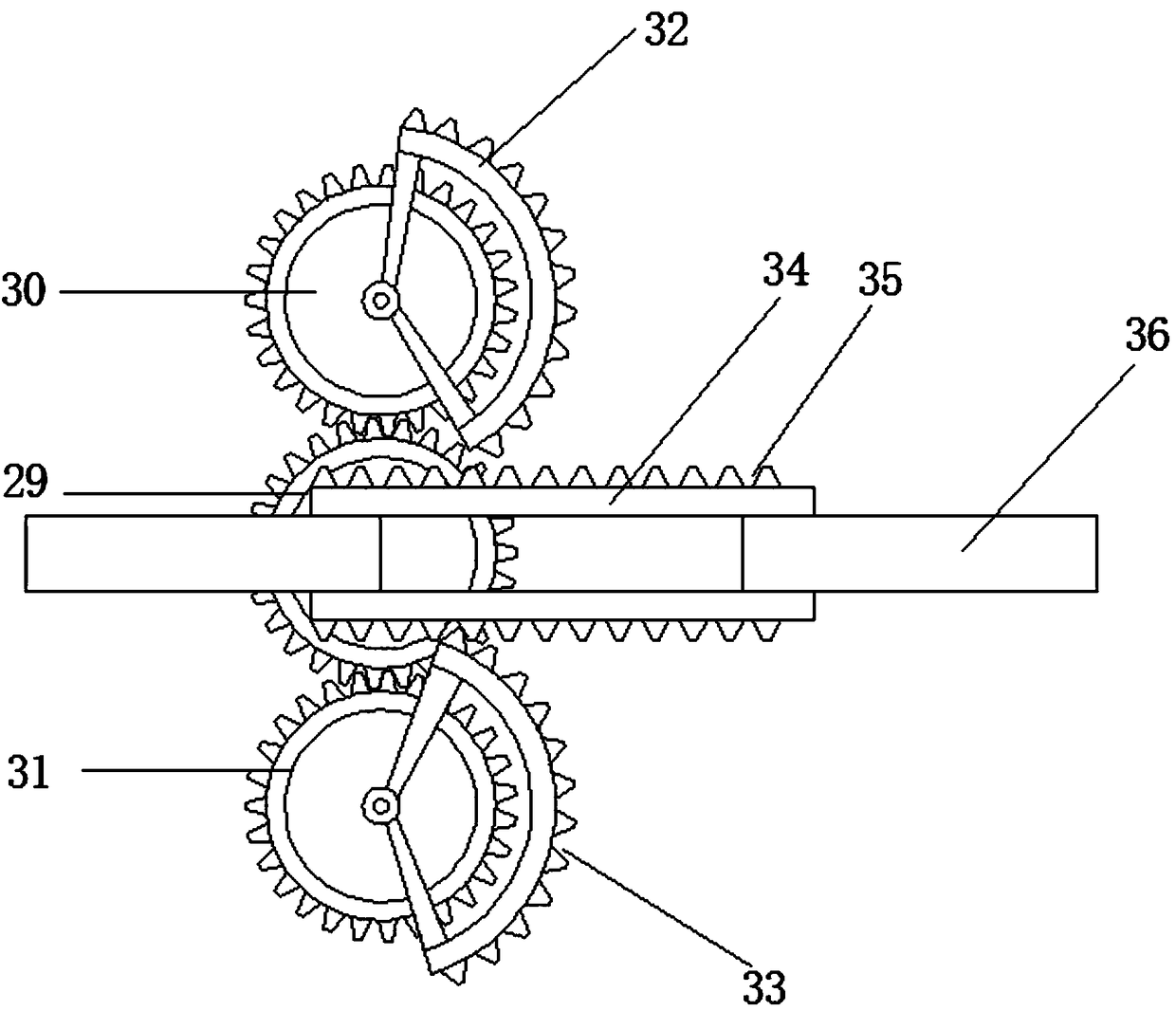

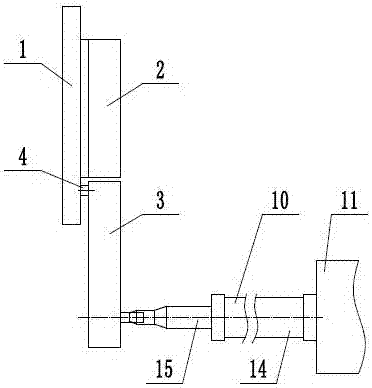

3D printer feeding mechanism

PendingCN109049708AImprove feeding frictionImprove feeding stabilityAdditive manufacturing apparatus3D object support structuresPulleyFeeding drive

The invention belongs to the field of 3D printing equipment, and discloses a 3D printer feeding mechanism. The 3D printer feeding mechanism comprises a feeding base; a feeding driving wheel is arranged on the feeding base; the feeding base is provided with a pressing unit matched with the feeding driving wheel; and the pressing unit comprises a groove pulley matched with the feeding driving wheel,and a pressing force adjusting module for adjusting the pressing force of the groove pulley. The 3D printer feeding mechanism is characterized in that a first annular groove with one contact point with raw materials is arranged on the side surface of the groove pulley; and a second annular groove with two symmetrical contact points with the raw materials and corresponding to the first annular groove is arranged on the side surface of the feeding driving wheel. The 3D printer feeding mechanism can realize stable, complete and precise outputting of the raw materials.

Owner:GUANGZHOU ELECTRONICS TECH

Head stitching machine for sock

InactiveCN103485079ADemagnetizationReduce adsorptionWork-feeding meansLinking machinesEngineeringElectromagnet

The invention provides a head stitching machine for a sock, belongs to the technical field of textile machinery and solves the technical problems that in the prior art, after the head of the sock is sewn, the sock cannot be automatically turned over, and the like. The head stitching machine comprises a rack; the right end of the rack is the discharge end of the sock; the bottom end of the sock is provided with a rubber magnetic sheet 1 and a rubber magnetic sheet 2; the bottom of a sock guide cylinder is provided with a discharge port for the sock to pass through, and is further fixedly provided with an electromagnet; an air cylinder is further fixed at the right end of the rack; the cylinder body of the air cylinder is fixed on the rack; the lower end of a piston rod is fixedly connected with a telescopic arm; a material containing basket is arranged right below the telescopic arm and is fixed on a material containing seat; the telescopic arm can be inserted in a material containing cylinder and can push the sock, so that the sock falls into the material containing basket. By adopting the head stitching machine for the sock, after the head of the sock is sewn, the sock can be automatically turned over, and the production efficiency of the sock is high.

Owner:HAINING SUNSHINE SOCKS MFG

Automatic punching machine with positioning function

ActiveCN113547365AEasy to collectWith collection functionMeasurement/indication equipmentsFeeding apparatusPunchingEngineering

The invention discloses an automatic punching machine with a positioning function, and relates to the technical field of machining. The automatic punching machine comprises a punching box, wherein a conveying assembly is arranged at the left side of the bottom of the inner wall of the punching box; a material pressing assembly is arranged at the left side of the top of the inner wall of the punching box; the material pressing assembly is provided with a positioning and pressing assembly; a punching assembly is arranged at the top of the inner wall of the punching box; a supporting assembly is arranged at the bottom of the inner wall of the punching box and positioned below the punching assembly; the supporting assembly is provided with a positioning assembly; and a controller is arranged at the right side of the top of the inner wall of the punching box. According to the automatic punching device with the positioning function, the position is adjusted and controlled through the positioning assembly, and the right side of a material is limited, so that the effect of precise positioning is achieved. The effects of precise positioning and automatic punching are achieved through the arrangement of the punching box, the conveying assembly, the material pressing assembly, the positioning and pressing assembly, the punching assembly, the positioning assembly and the controller. Automatic positioning and punching are achieved, and the punching work efficiency is improved.

Owner:徐州市晶鑫新材料有限公司

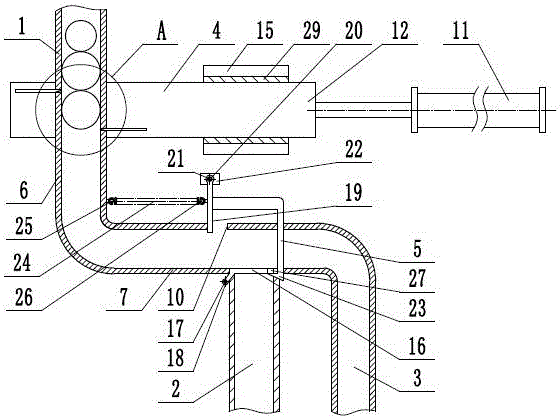

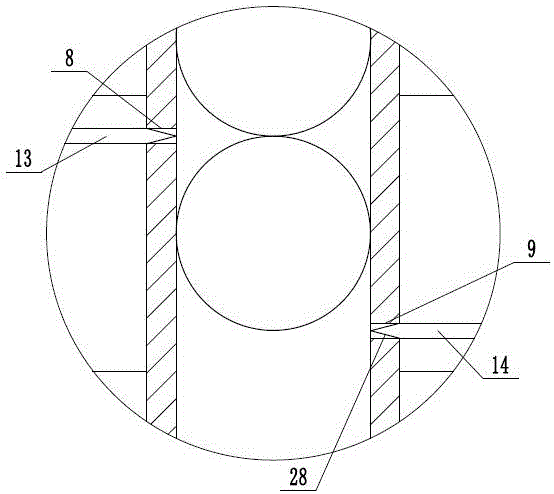

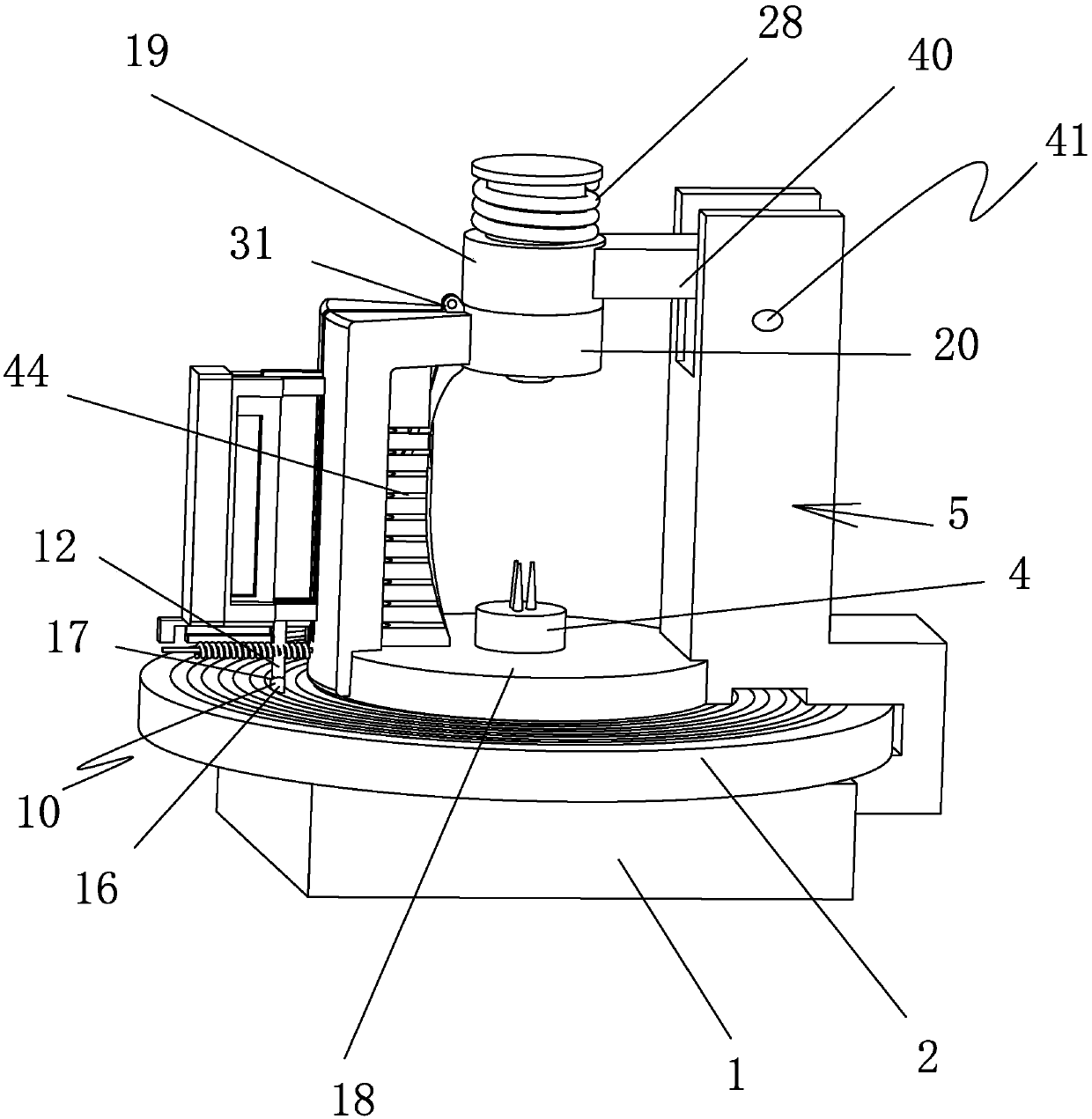

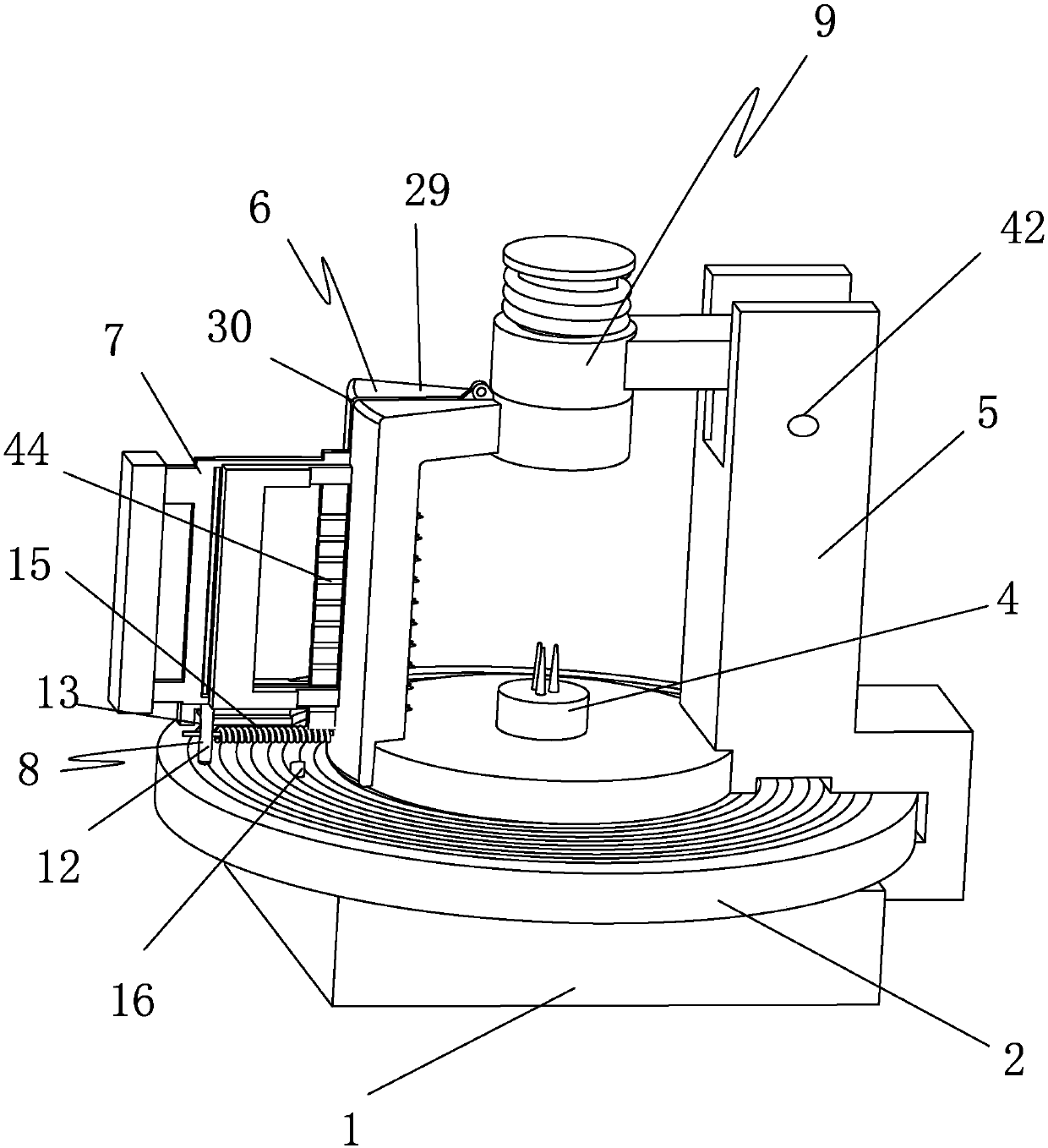

Branching device of cylindrical workpiece

The invention provides a branching device of a cylindrical workpiece and belongs to the technical field of material supply machines. The device comprises a material isolating mechanism and a branching mechanism. A slide block of the material isolating mechanism is arranged on a guide rail support in a left and right sliding manner, a left material isolating plate and a right material isolating plate are mounted on the slide block, the left material isolating plate can be inserted into a left isolating slot of a supply material channel, a right material isolating plate can be inserted into a right isolating slot of the supply material channel, the left end of a baffle plate of the branching mechanism is hinged to the left upper end of a first branching material channel through a baffle plate pin roll, a baffle plate torsional spring and the baffle plate pin roll are coaxially arranged, a hanging slot is formed in the right end of the baffle plate, the upper end of a detection plate is hinged to a supporting seat of the detection plate through a detection pin roll, the baffle plate torsional spring and the detection pin roll are coaxially arranged, the lower end of the detection plate is inserted into an upper isolating slot, a hook is fixed on the right side of the detection plate, and two ends of a tension spring are separately connected to a first tension spring support and a second tension spring support. The branching device provided by the invention can screen and supply two cylindrical workpieces which are different in outer diameter in a branched manner, and is reasonable in structure and good in material supply stability.

Owner:魏俊杰

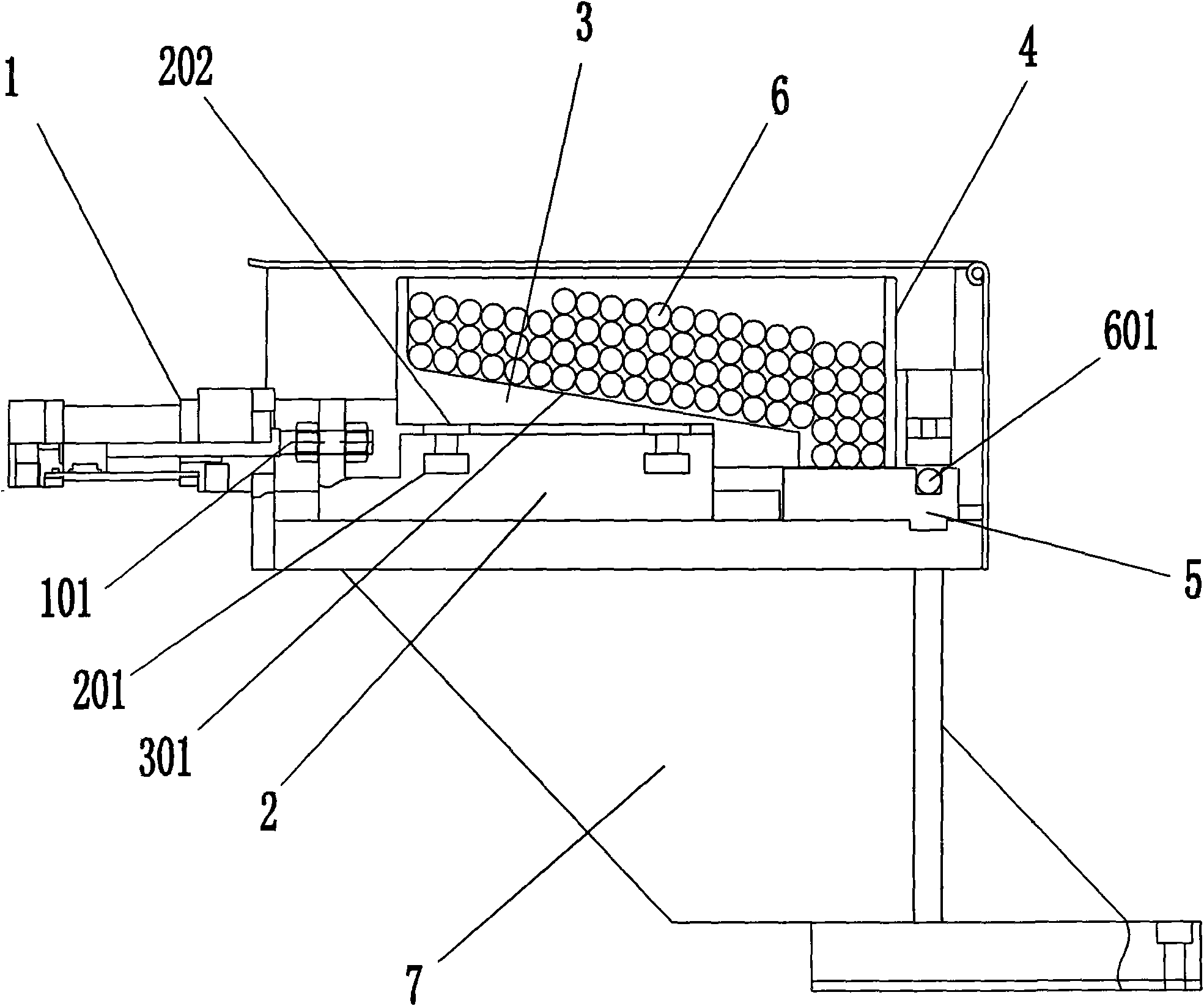

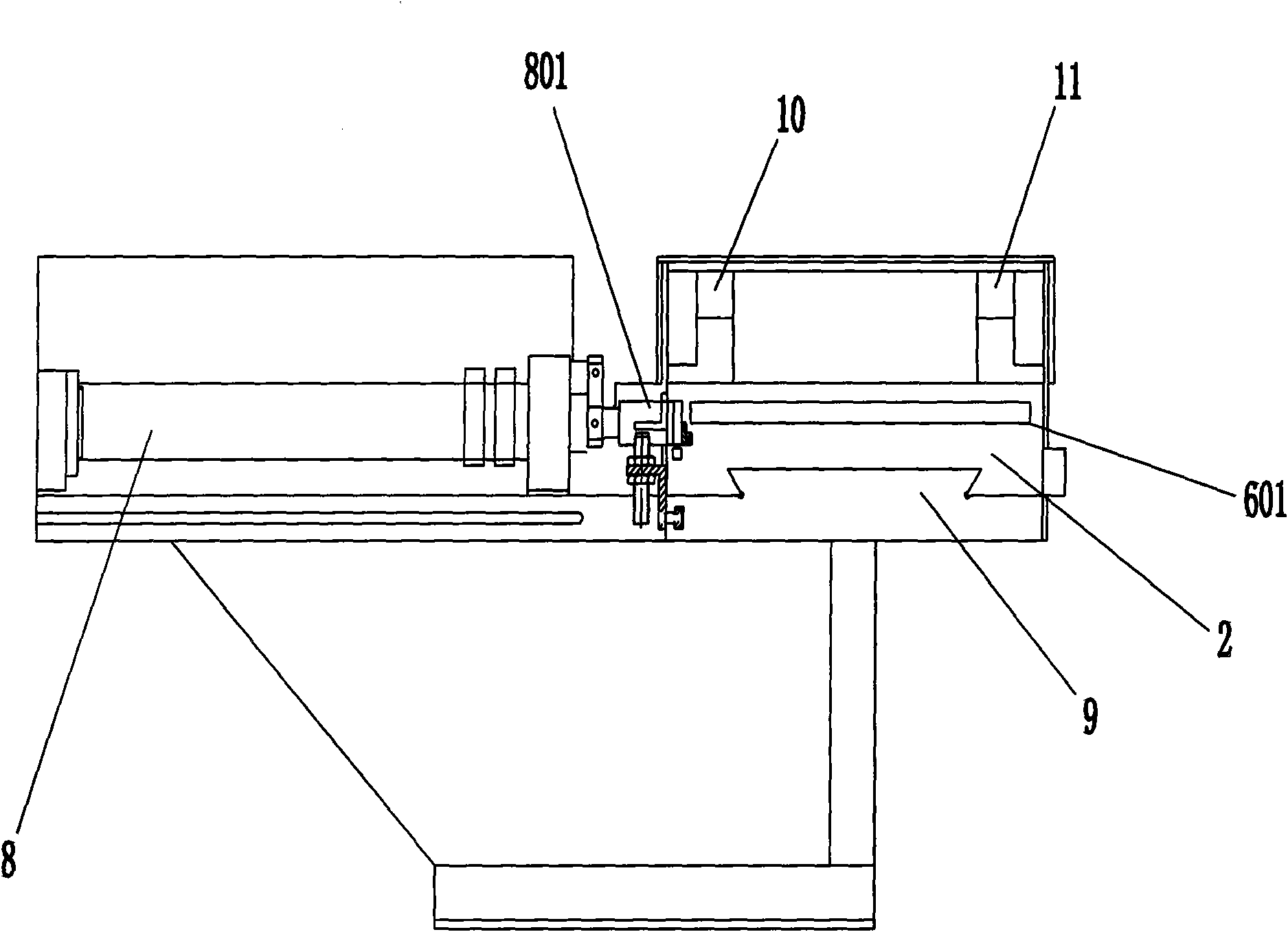

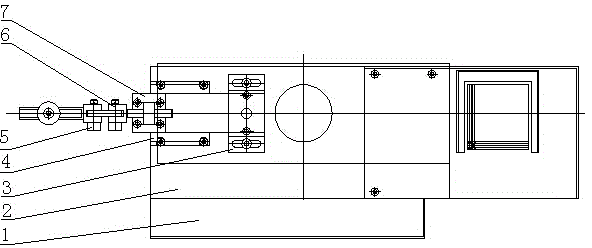

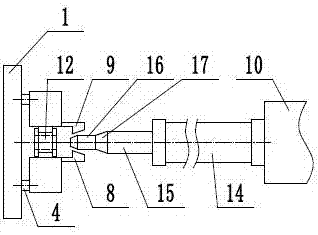

Automatic feed mechanism of numeric-control drill tip grinder

InactiveCN101590617AReduce manufacturing costThere will be no material jamDrilling toolsDrillEngineering

The invention discloses an automatic feed mechanism of a numeric-control drill tip grinder, which comprises a base, a hopper base arranged on the base and a guide block, wherein a feed bin is fixedly arranged on the hopper base, a guide board is movably fixed on the side wall of the discharge hole of the feed bin, the lower end of the guide board is provided with a gap, and an open slot is formed between the gap and the guide block. The automatic feed mechanism of the invention can effectively solve a jamming problem in feeding, and has the advantages of quick feeding, good feeding stability, high feeding efficiency, simple structure, and the like. A plurality of grinders can be simultaneously operated for production by one person, and production cost can be greatly reduced for companies.

Owner:SHENZHEN GOLD DRILL TOOLS & MFR TECH

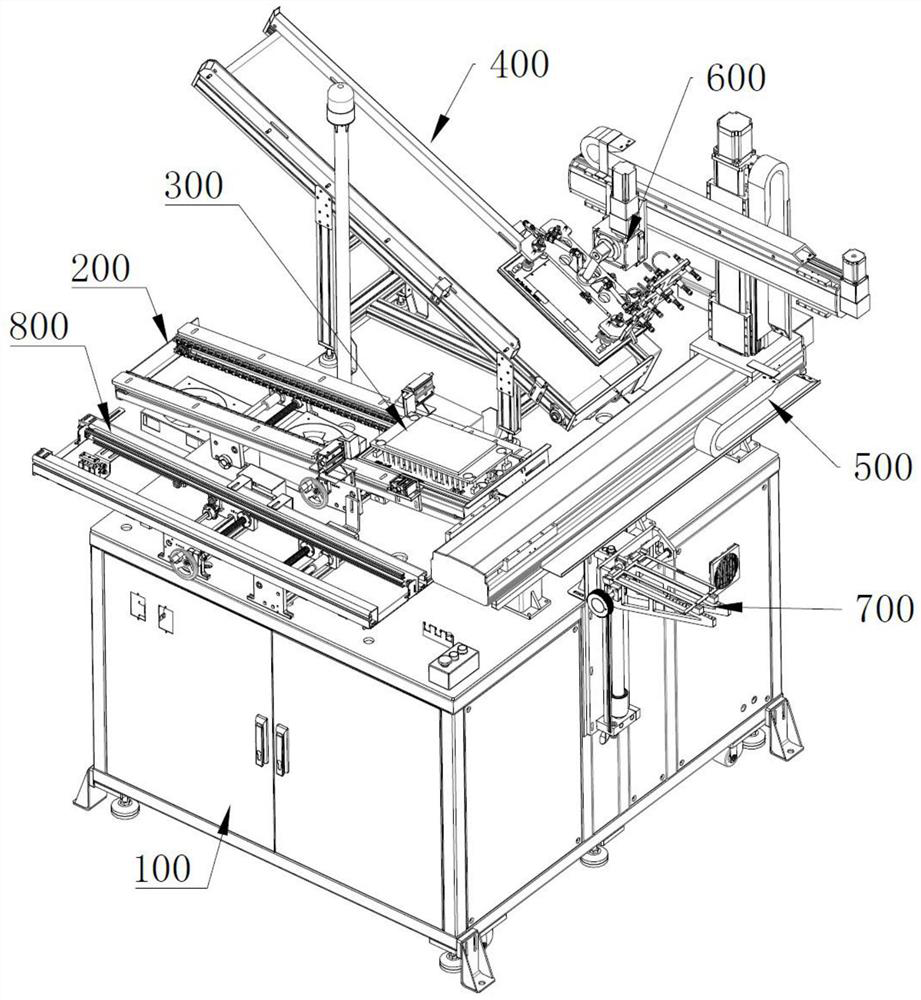

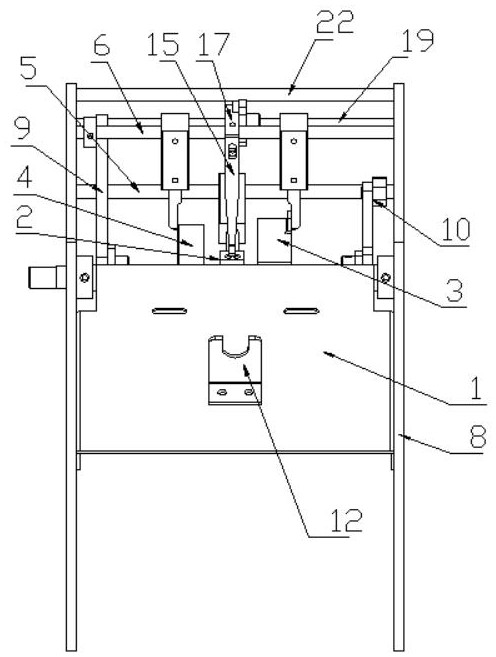

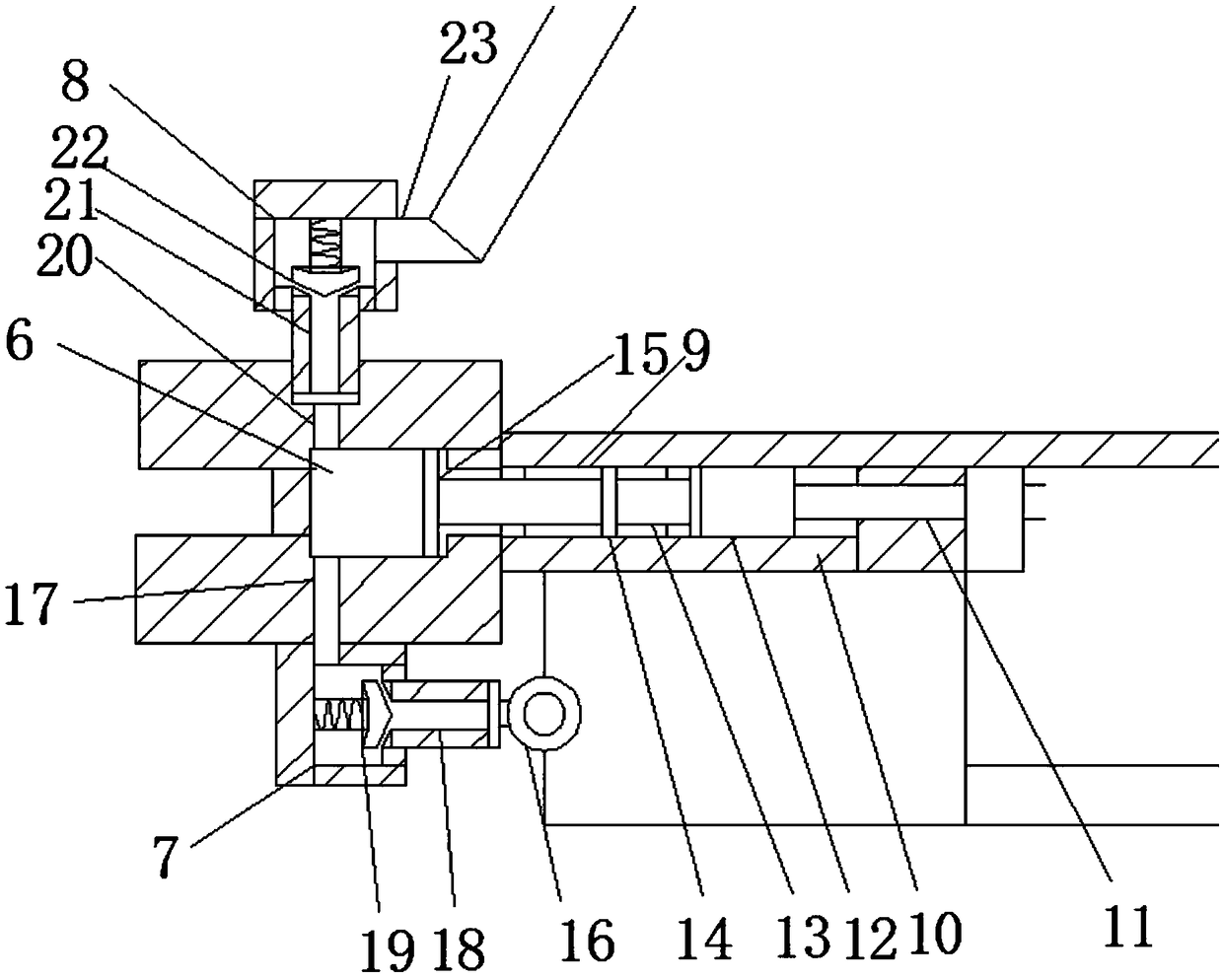

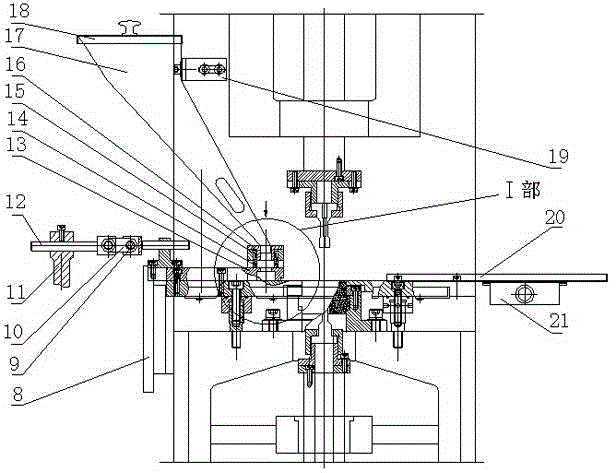

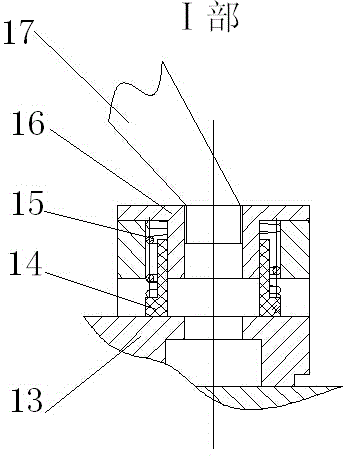

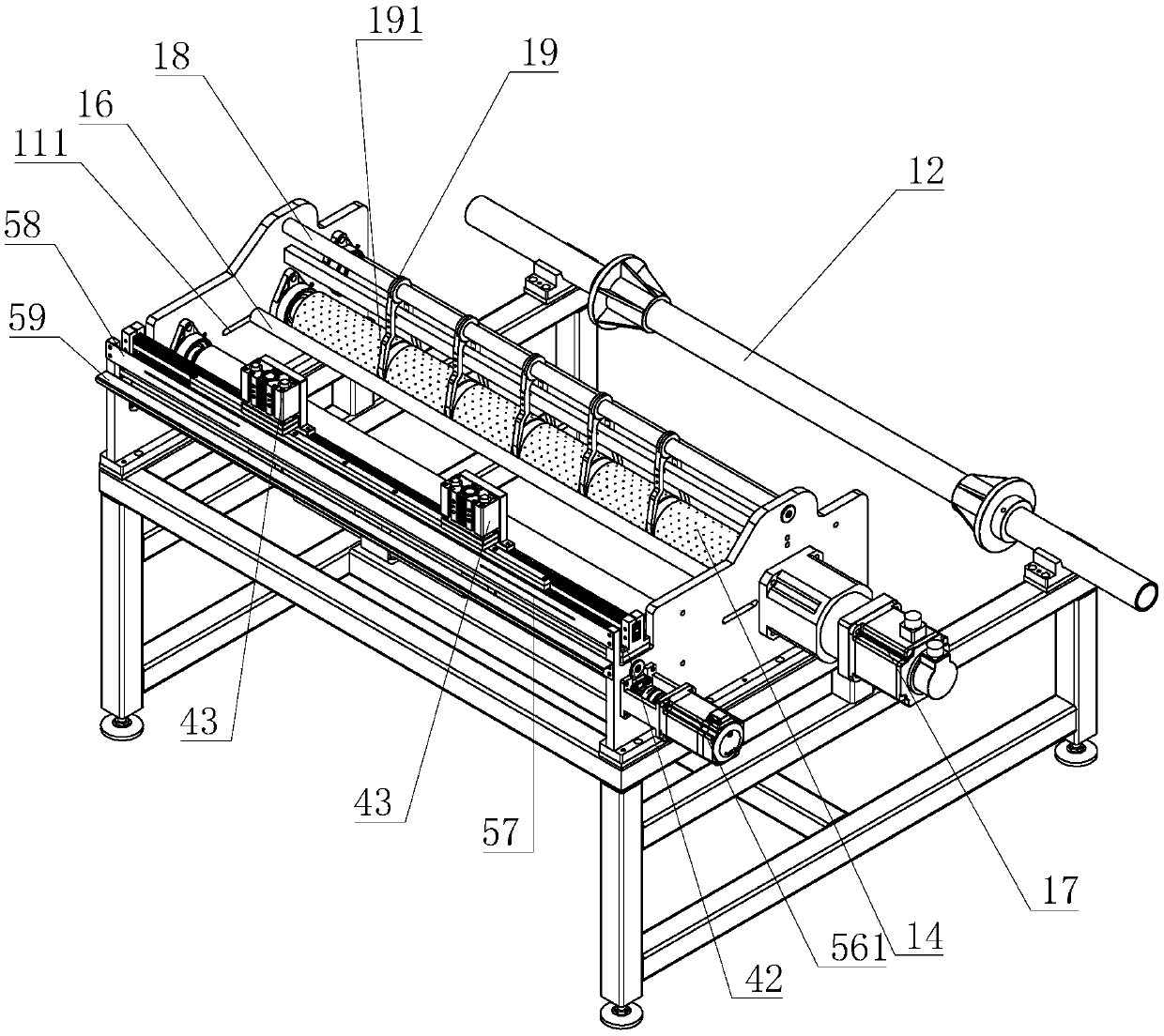

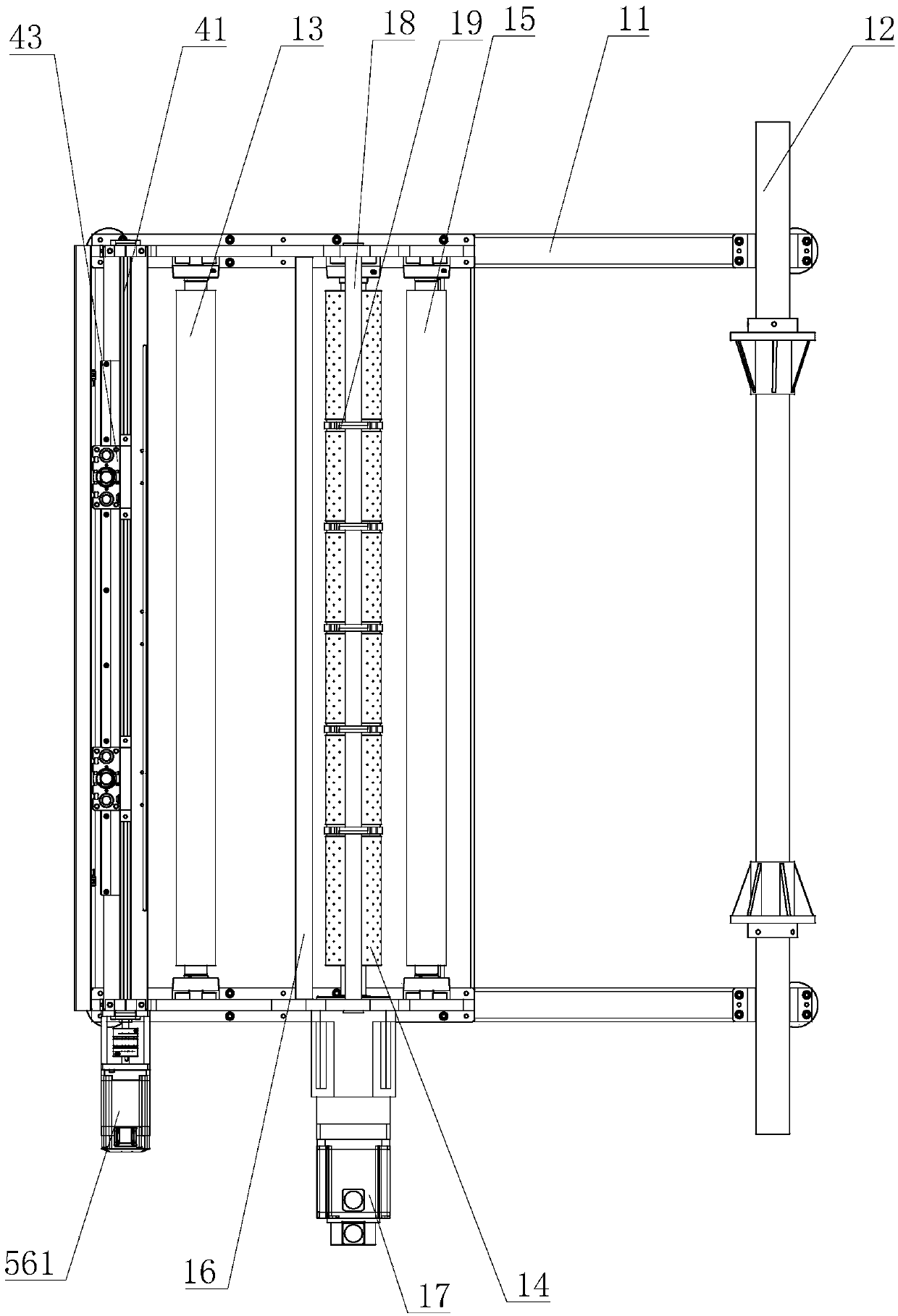

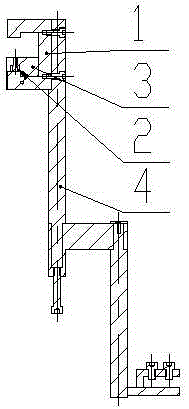

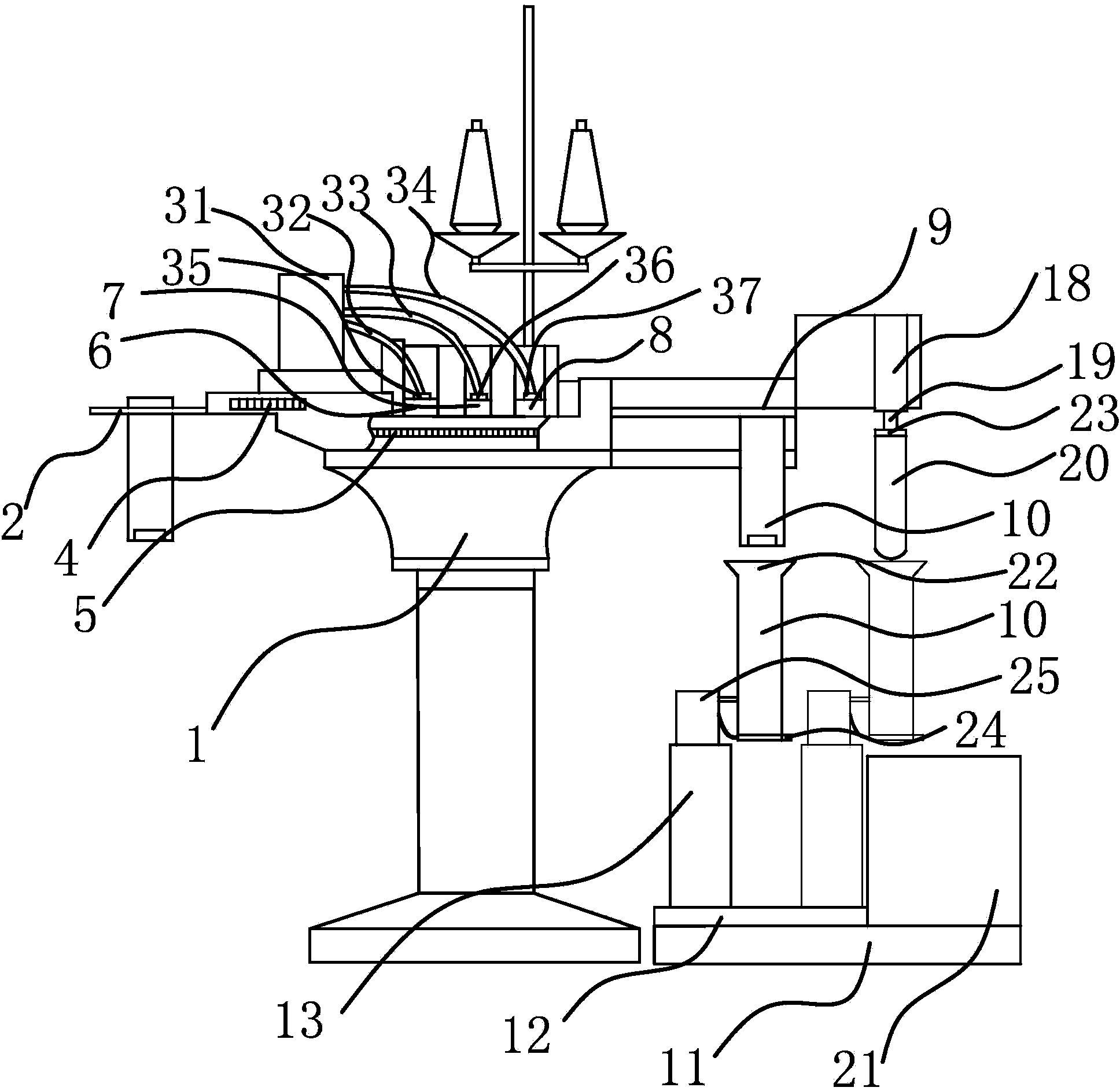

Catheter feeding device in medical assembling machine

InactiveCN105501864AAvoid collisionImprove feeding stabilityLoading/unloadingMechanical conveyorsEngineeringMedical device

The invention provides a catheter feeding device in a medical assembling machine and belongs to the technical field of manufacturing equipment of medical devices. The catheter feeding device in the medical assembling machine solves the technical problems such as low feeding and replacing efficiency of catheters and so on at present. The catheter feeding device in the medical assembling machine comprises a loading rack arranged on one side of a catheter loading device and a feeding trolley capable of moving; a first conveying passage is arranged on the loading rack, while a second conveying passage is arranged on the feeding trolley; a lifting table capable of driving a work bin to move up and down is arranged in the loading rack; a positioning structure for positioning the feeding trolley and the loading rack when the first conveying passage and the second conveying passage are aligned to and communicate with each other are arranged between the feeding trolley and the loading rack; directing plates are fixed on the loading rack and on two sides of the first conveying passage, respectively; guiding plates are fixed on the feeding trolley and on two sides of the second conveying passage, respectively; the directing plates on the two sides of the first conveying passage form, in a vertical direction, a guiding channel for directing the work bin to move up and down. The catheter feeding device in the medical assembling machine has the advantage of rapidly and stably replacing a guide rail and the work bin.

Owner:MAIDER MEDICAL IND EQUIP

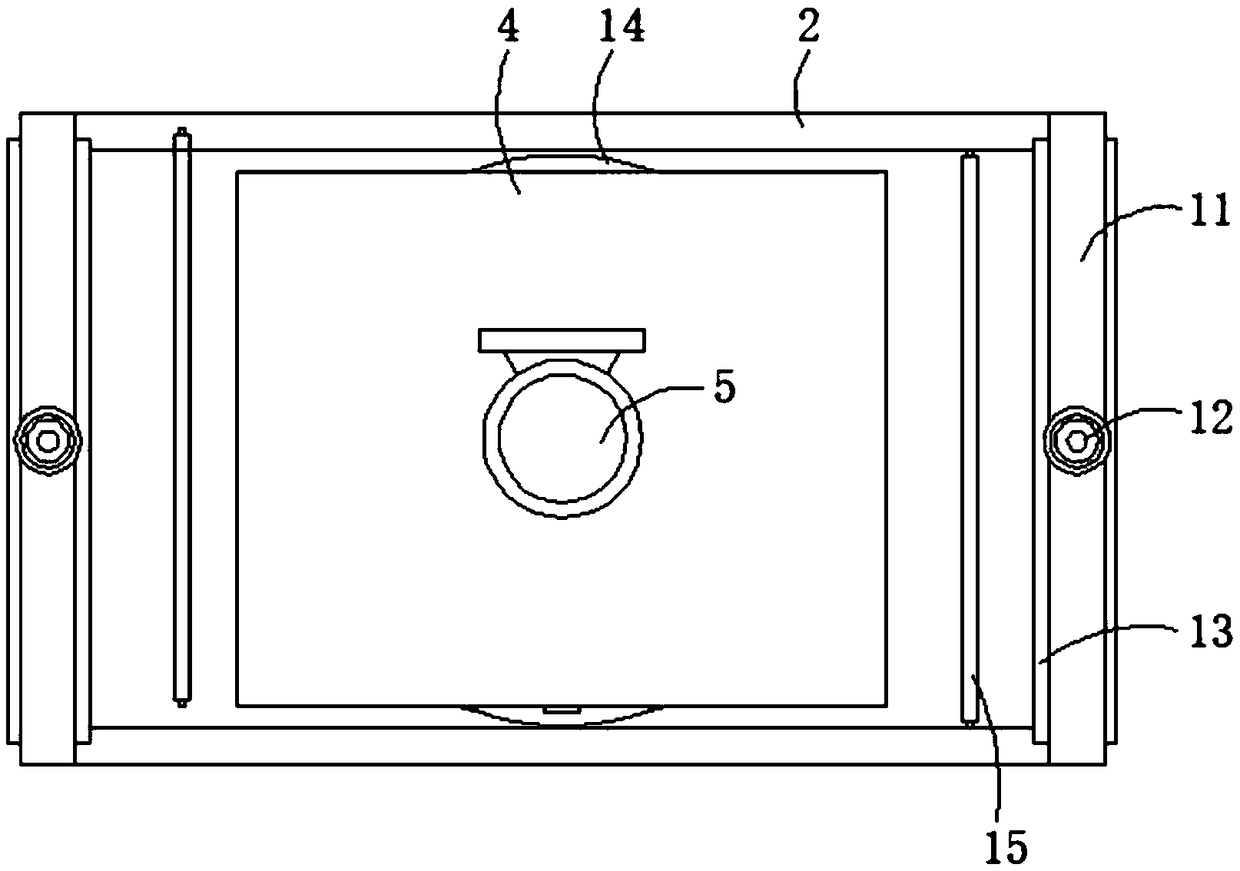

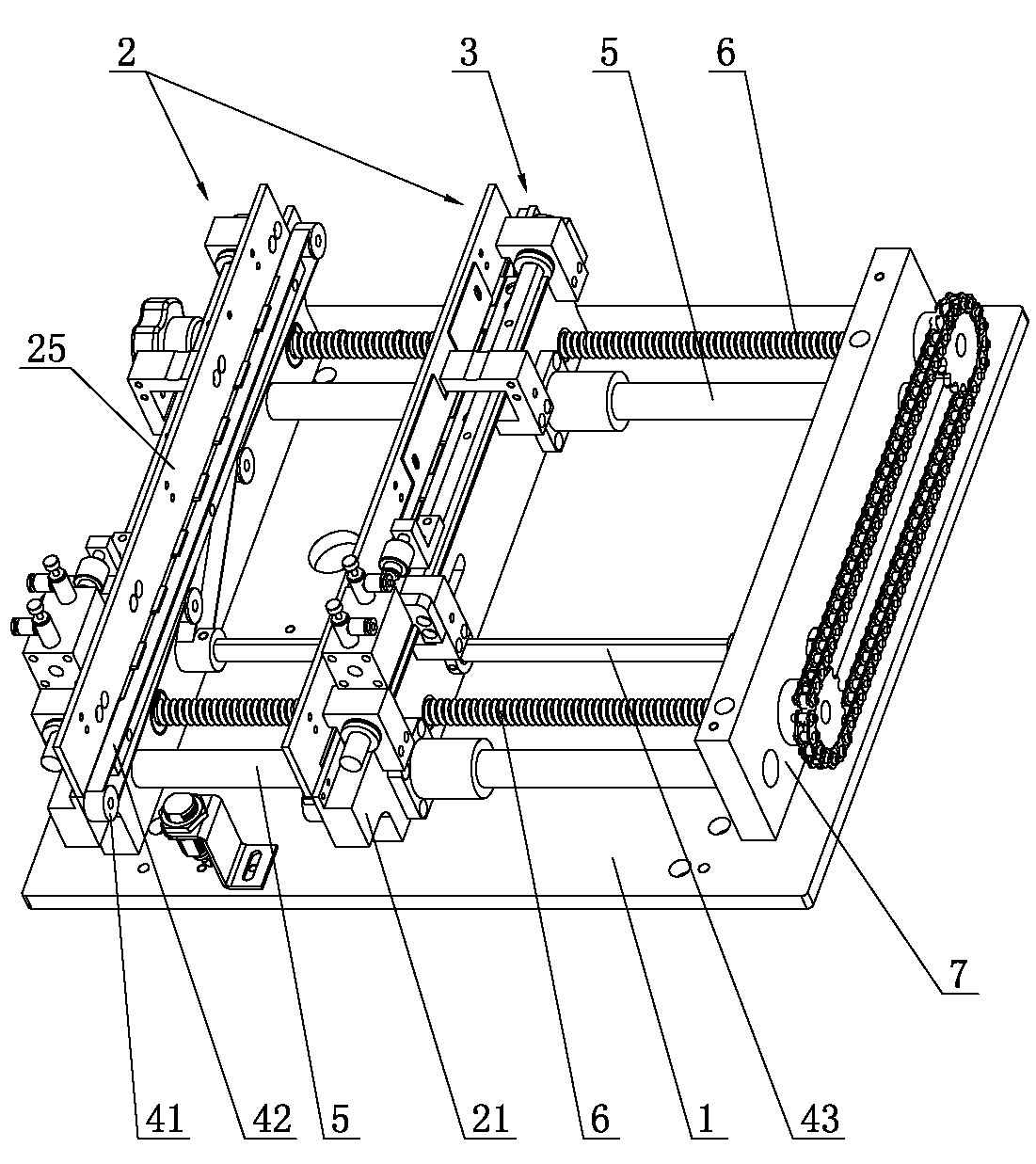

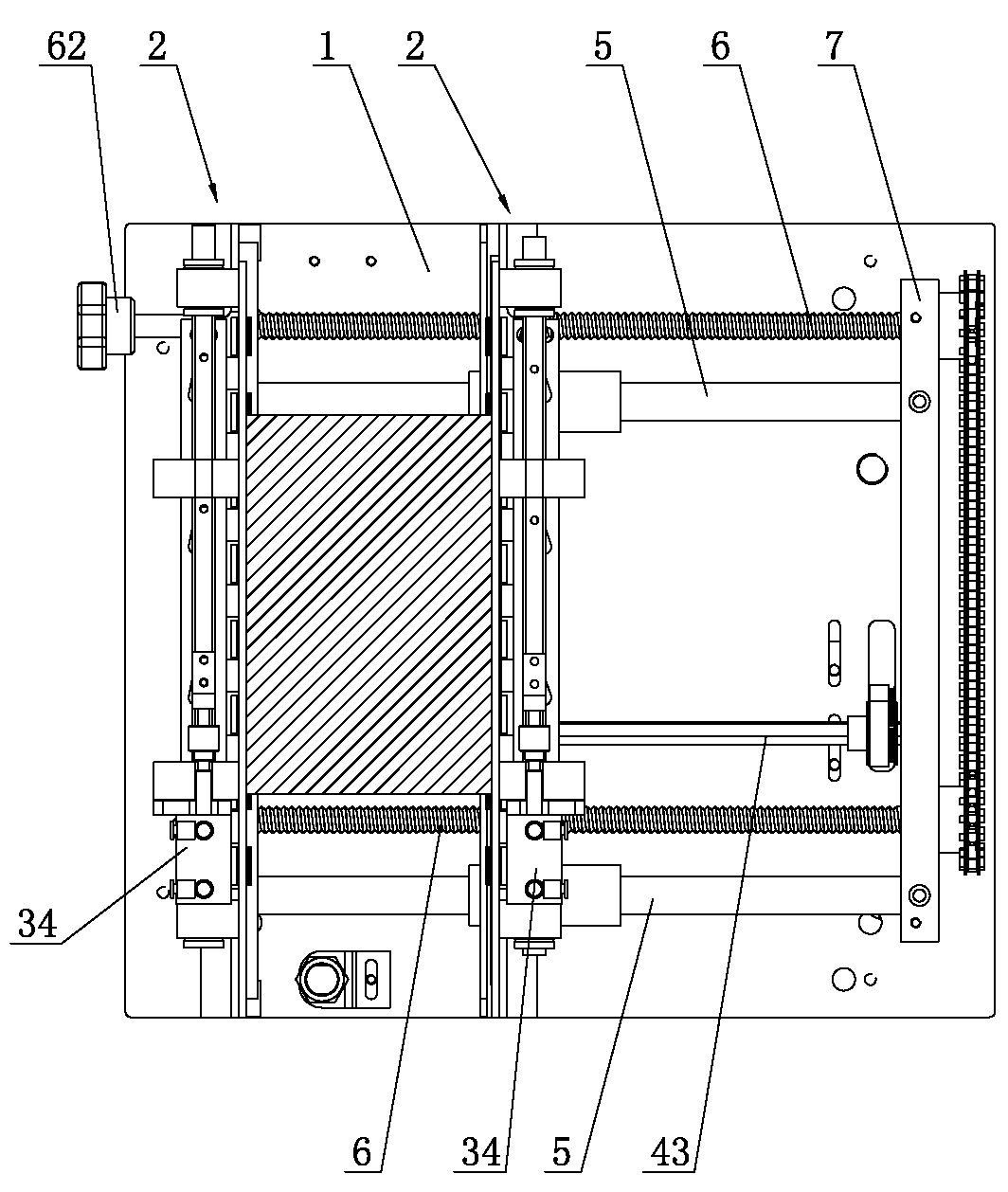

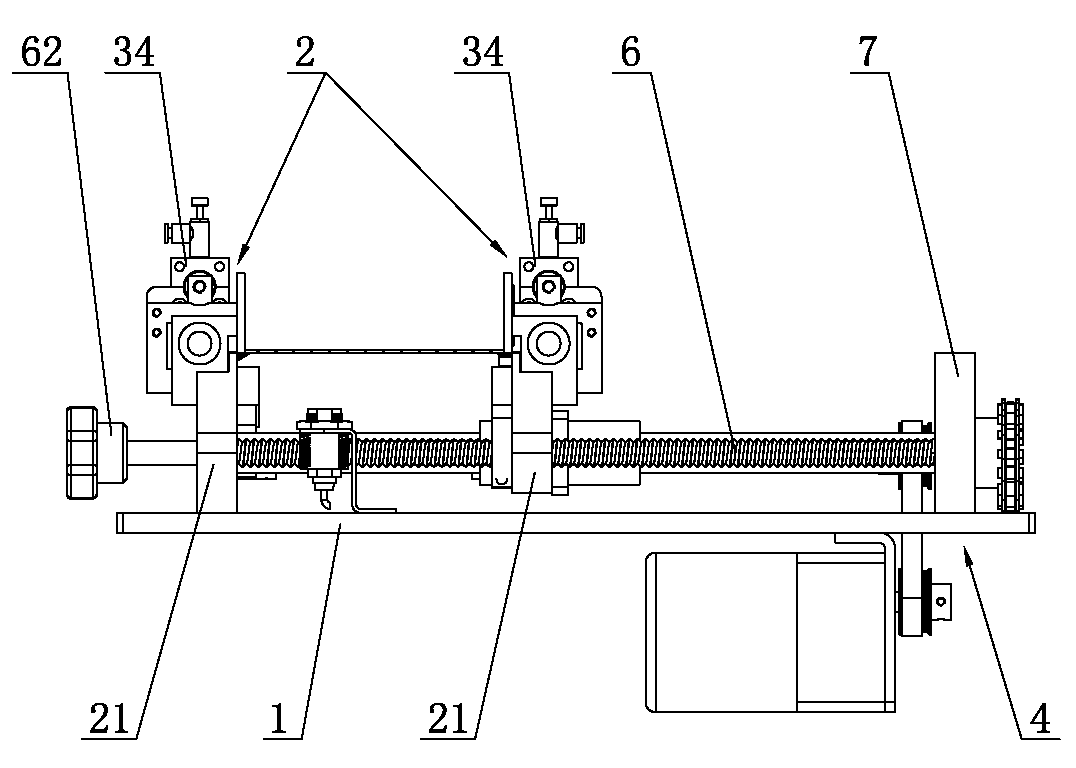

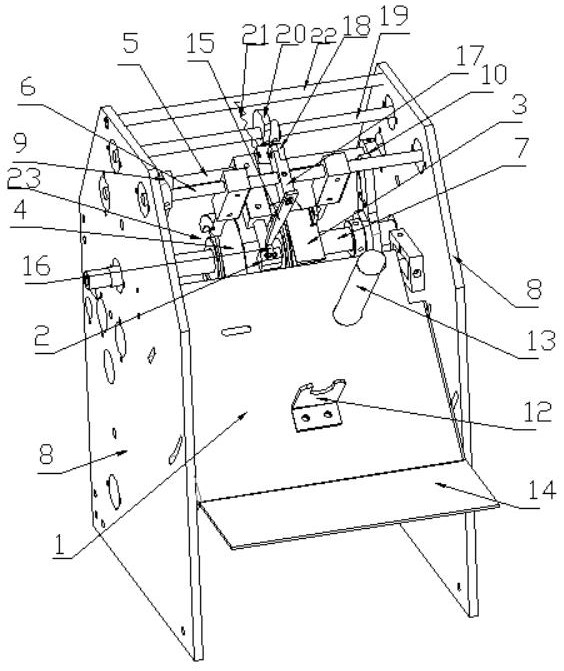

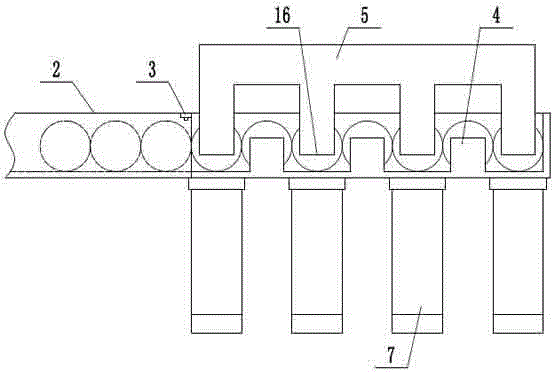

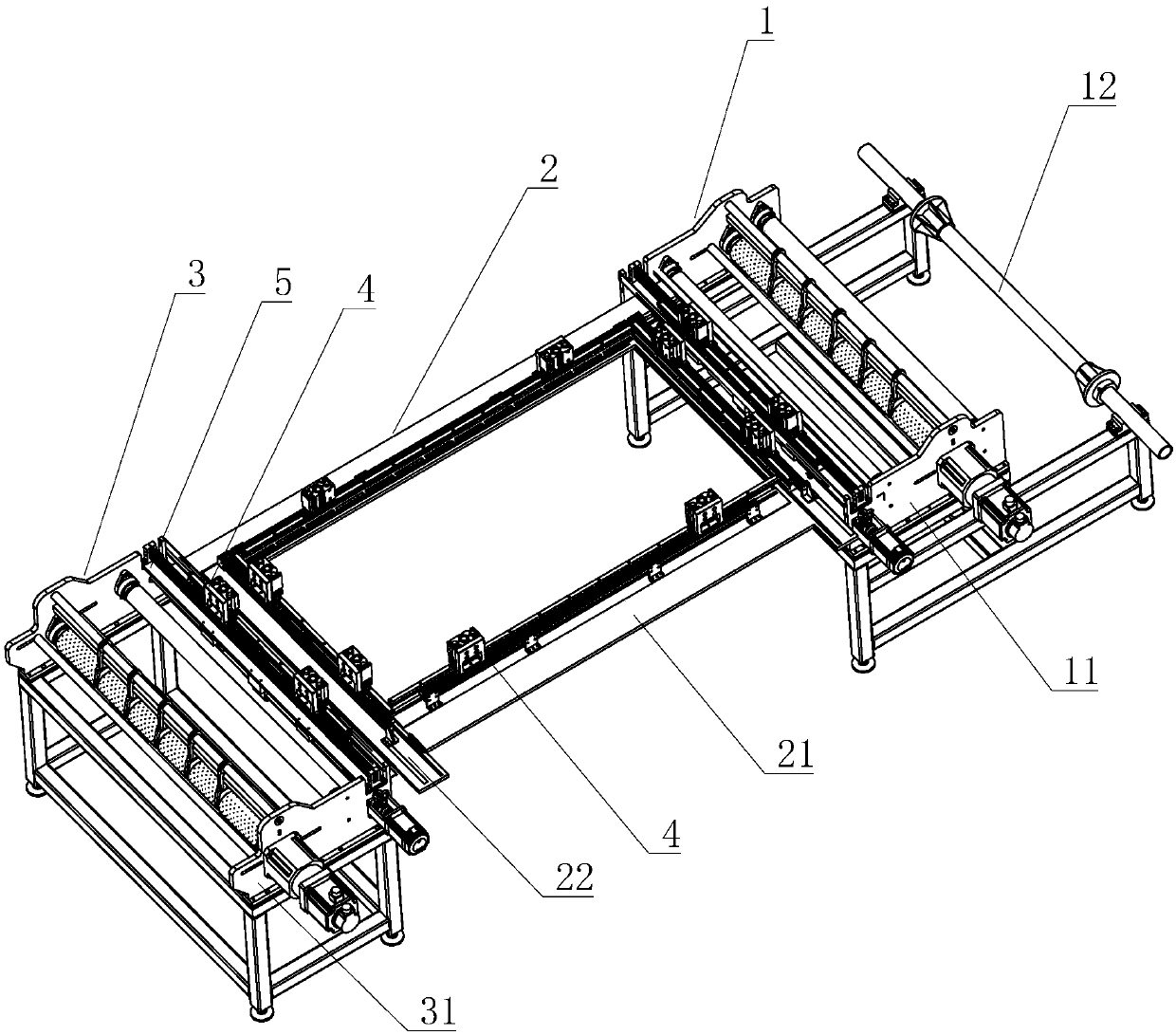

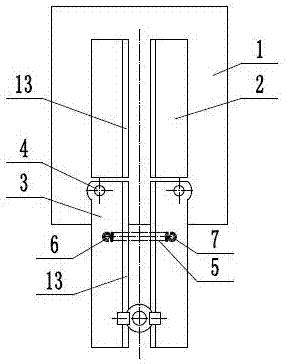

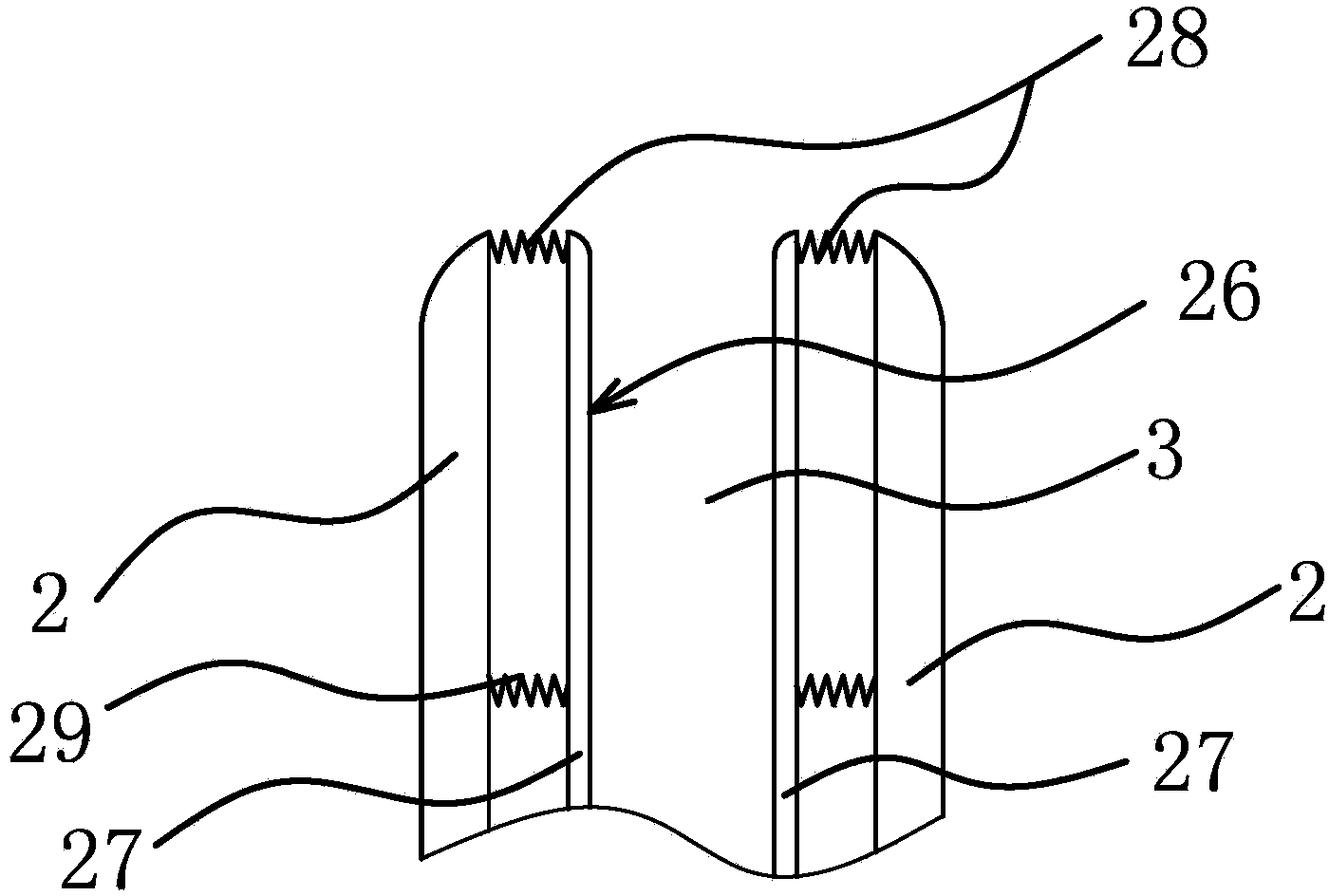

One-by-one bi-directional feeding device for PCBs

The invention relates to the technical field of PCB assembly, in particular to a one-by-one bi-directional feeding device for PCBs. The one-by-one bi-directional feeding device comprises a base plate and two board separating assemblies. Each board separating assembly comprises an installation plate installed on the base plate, and multiple board supporting blocks are arranged on the inner sides of the installation plates at intervals. A pushing plate and a board separation driving mechanism are installed on the upper edge of each installation plate. The pushing plates are provided with multiple extending teeth, and each extending tooth is located in the interval between every two adjacent board supporting blocks. Conveying assemblies are installed on the inner sides of the installation plates and lower than the bearing faces of the board supporting blocks, and baffles are arranged above the board supporting blocks. The bi-directional feeding device can be used for feeding materials to two different machining devices through bi-directional feeding, so that investment cost for a production line is greatly reduced; feeding stability is high, mutual friction between the adjacent PCBs can be effectively avoided, the rejection rate of electronic products is effectively decreased, and practicability is high.

Owner:海宁经开产业园区开发建设有限公司

Coconut coir stripping apparatus

The invention discloses a coconut coir stripping apparatus, which comprises a base, wherein a rotating disc is arranged on the base, a motor capable of driving the rotating disc to rotate is arrangedin the base, a coconut fixing seat is arranged in the middle of the upper end surface of the rotating disc, a support frame is arranged on one side of the base, and is movably connected to a cutter holder, a coir stripping cutter capable of moving back and forth relative to the cutter holder is movably arranged in the cutter holder, a driving mechanism capable of driving the feeding of the coir stripping cutter into a coconut during the rotating of the rotating disc is arranged between the coir stripping cutter and the rotating disc, and the inner side of the cutter holder is provided with a coir stripping insertion needle capable of being inserted into the coconut endocarp before feeding the coir stripping cutter so as to pre-strip the coconut. A purpose of the present invention is to overcome the disadvantages in the prior art and provide the coconut processing apparatus, wherein the coconut processing apparatus can sequentially perform coconut coir tearing, cutter feeding and coir stripping, such that the coir stripping cutter can be effectively protected from being cut off or lost.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

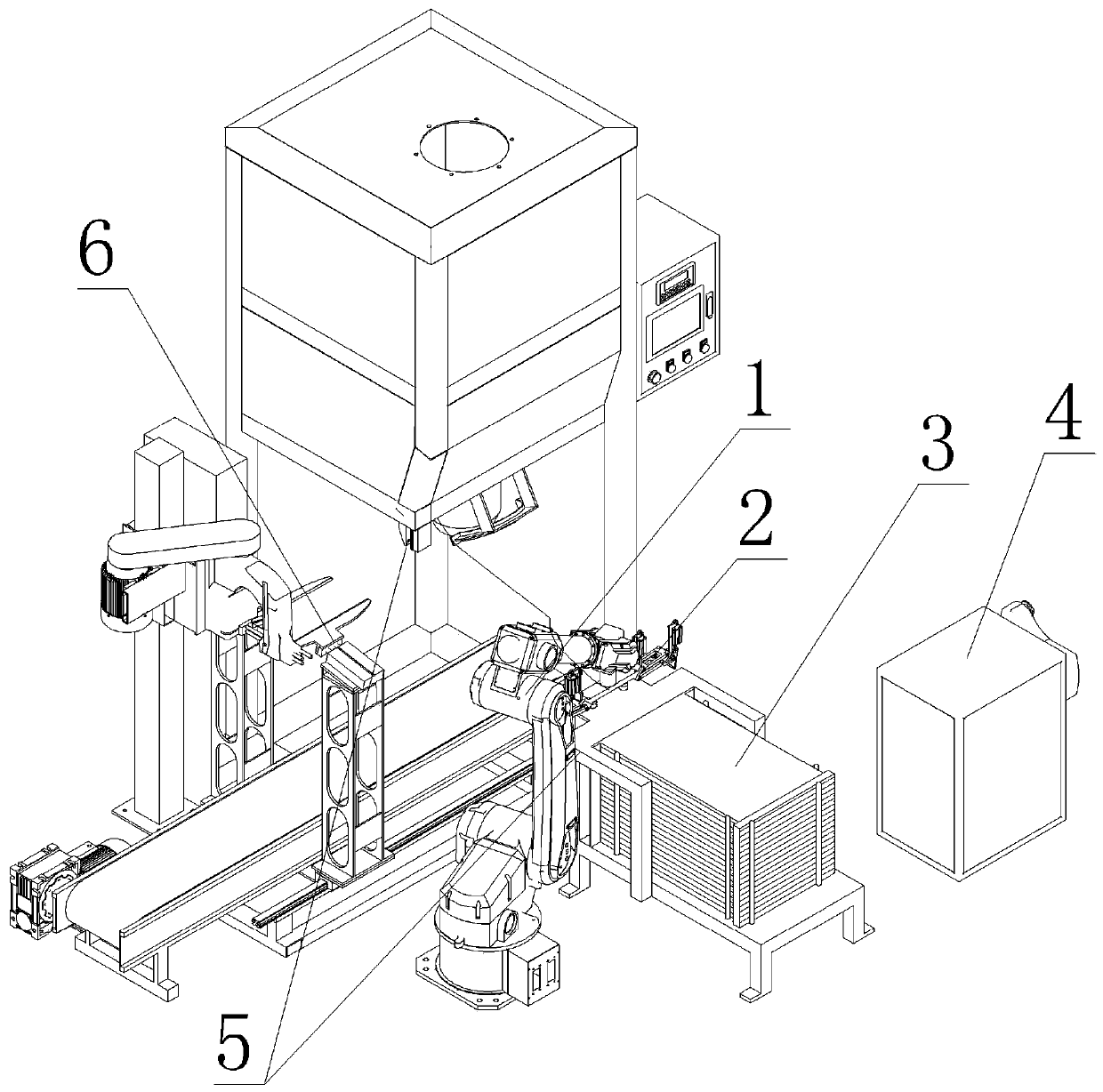

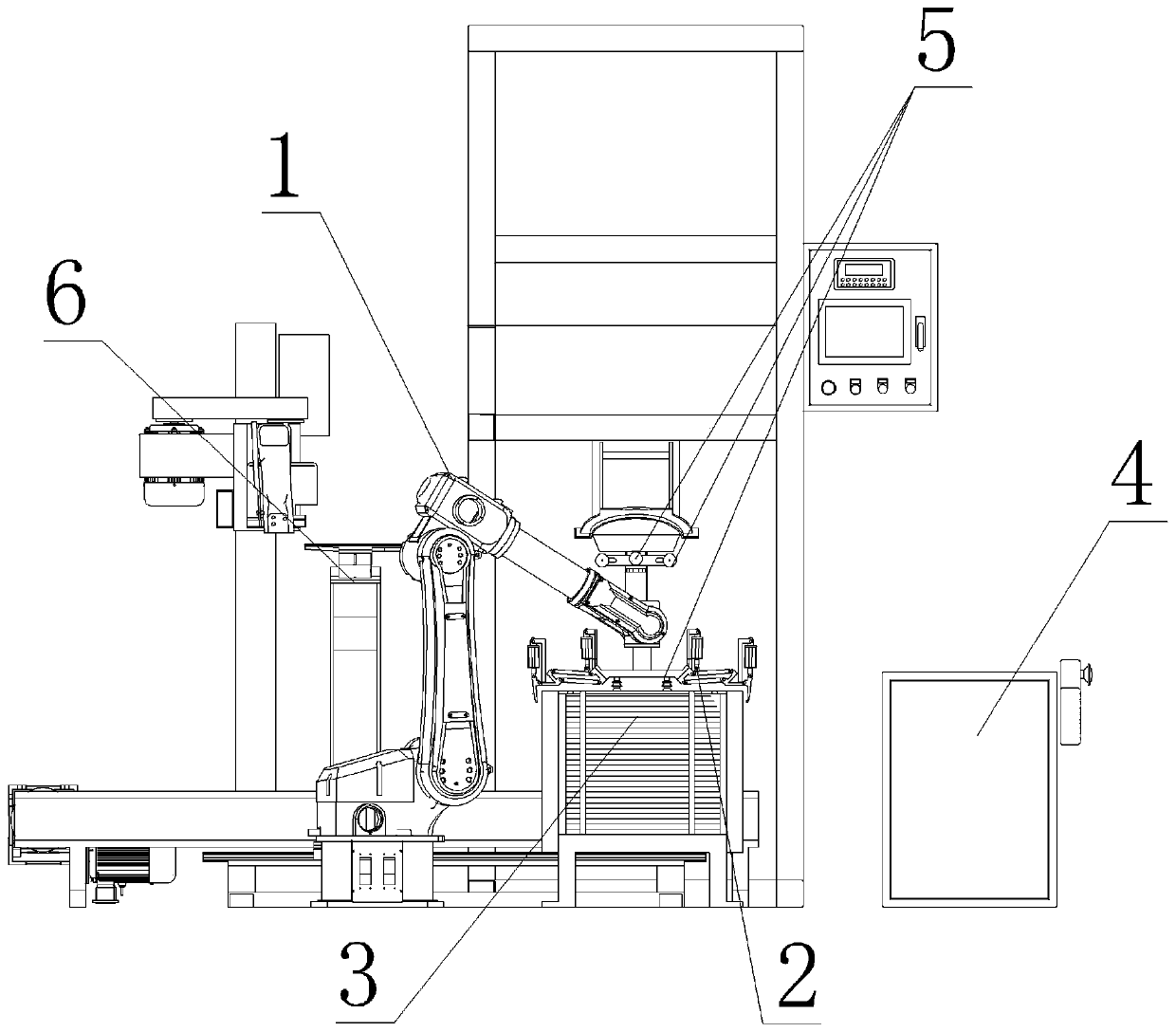

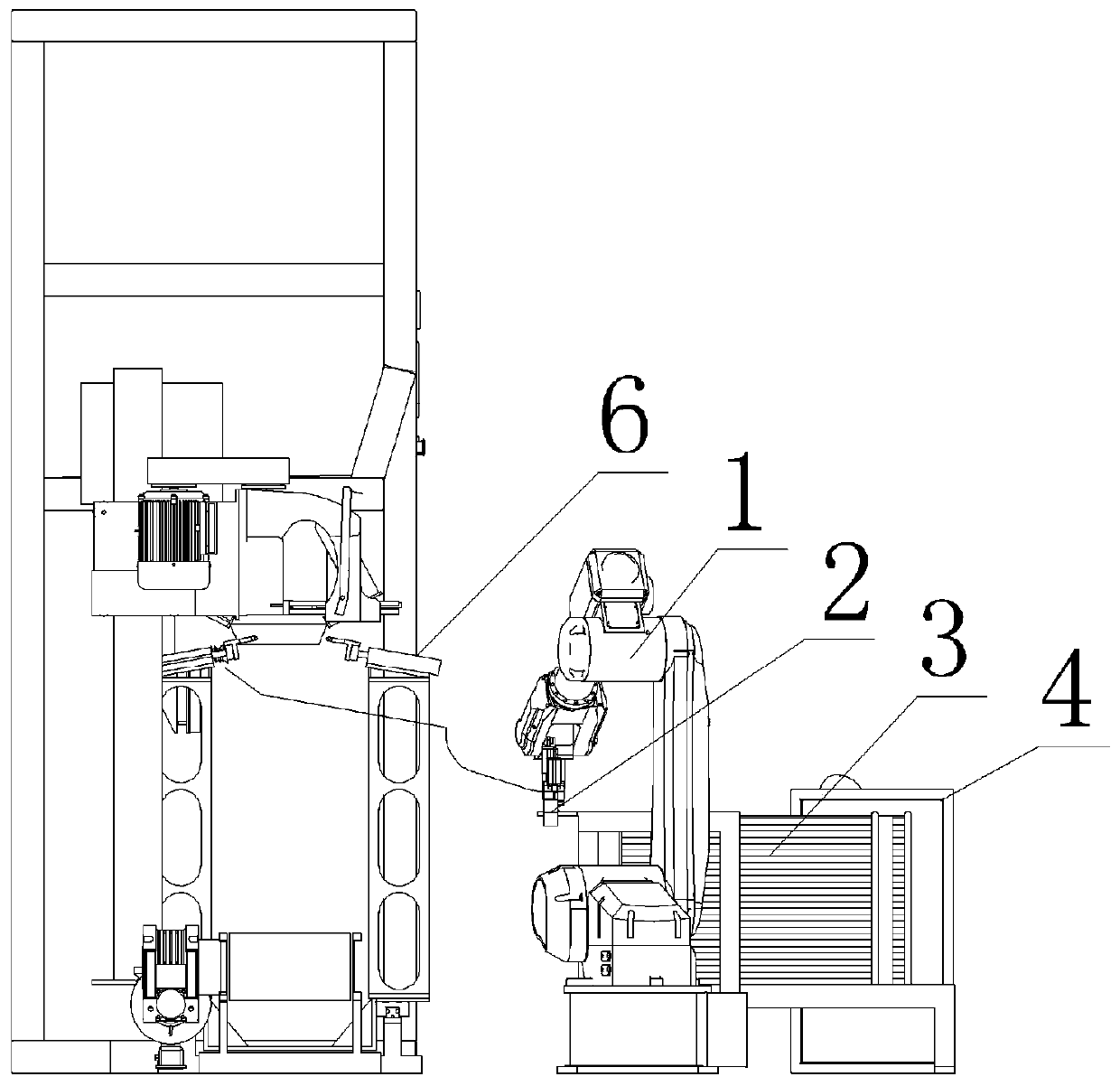

Powder packaging robot intelligent bagging system

InactiveCN109835531AHarm reductionImprove work efficiencyWrapper twisting/gatheringManipulatorIndustrial robot

The invention discloses a powder packaging robot intelligent bagging system. The system consists of six parts, namely a six-axis industrial robot body, a grabbing mechanical arm mechanism, an empty bag library, a feeding trolley, a special coordinate point detection mechanism and a control cabinet, the controller controls the six-axis industrial robot to rotate, ascend, descend and move in the working coordinates, the controller controls the grabbing mechanical arm mechanism to sleeve the bag opening of the packaging empty bag onto a discharging port of a packaging machine, the empty bag library can be controlled to realize intelligent bag supplying, the feeding trolley is controlled to convey the bag filled with materials to the inlet of the sewing machine along the track. The system canautomatically sleeve the seam opening of the packaging equipment of the round discharging opening of the universal powder packaging machine with the size of 10-50 kg, manual operation is replaced, andfull-automatic packaging is realized.

Owner:孙志宇

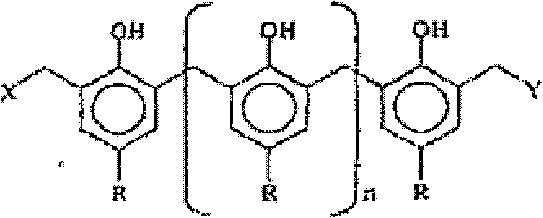

Process for producing thermoplastic elastomer composition

The invention discloses a process for producing a thermoplastic elastomer composition. The method relates to a dynamic heat treatment of ethylene-alpha-olefin copolymer rubber (A) and polyolefin resin (B) in the presence of alkylphenol resin (C) and metal halide (D) in a melt kneading apparatus, wherein the metal halide (D) is powder, and a mixture of the powder of the metal halide (D) and a particulate material having a average particle diameter of 0.1 [mu] m to 3 mm is continuously fed into the melt kneading apparatus.

Owner:SUMITOMO CHEM CO LTD

Clamping edge-type feeding device

InactiveCN105964823AGood for sliding back and forthGuaranteed not to moveMetal-working feeding devicesPositioning devicesEdge typeEngineering

The invention provides a clamping blade type feeding device, which belongs to the technical field of mechanical processing. It includes a feeding mechanism, a longitudinal guiding mechanism, and a horizontal guiding mechanism. The feeding support of the feeding mechanism can slide left and right and is set on the guide rod. The roller is rotatably arranged on the upper end of the pull rod and is located in the roller groove of the cam. The lower guide wheel of the longitudinal guide mechanism is rotatably arranged on the longitudinal guide support, and the upper guide wheel is rotatably arranged on the upper guide wheel bracket. The upper guide wheel The bracket can slide up and down and is set on the longitudinal guide support. The lower end of the adjustment screw rod is connected to the upper guide wheel bracket. The upper end of the adjustment screw rod is provided with an adjustment handwheel. rack. The invention ensures that the plates do not move during the feeding process, and the feeding stability is good.

Owner:CHENGDU SHUYUNDA TECH CO LTD

Shoe-shaped gold ingot machine and paper folding process

ActiveCN112141769ASolve the disadvantages of folding one side moreReduce R&D investment costsRegistering devicesFolding thin materialsPaper sheetManufacturing engineering

The invention provides a shoe-shaped gold ingot machine and a paper folding process. The shoe-shaped gold ingot machine comprises a supply system, a before-folding conveying system, a folding system and a stacking system; the supply system comprises a bin; the bin comprises a bottom plate with the bottom obliquely arranged; a feed assembly is provided at the top of the bin; and the feed assembly comprises a swingable negative-pressure suction nozzle, and a clamping jaw capable of being inserted between the last piece of shoe-shaped gold ingot paper and dozens of shoe-shaped gold ingot paper. The paper folding process for the shoe-shaped gold ingot machine is a sheet-shaped gold ingot paper folding process, and comprises a sheet-shaped gold ingot paper feeding step, a folding and edge opening step and a large and small angle folding step. The paper folding machine utilizes a negative-pressure adsorption mode to implement single-piece feeding of shoe-shaped gold ingot paper to achieve good feeding stability, and performs edge opening treatment at a paper outlet of the folding machine to provide necessary conditions for subsequent small-angle folding so as to effectively prevent paperstacking in the subsequent step due to error accumulation of position precision. The process solves the problem that the existing shoe-shaped gold ingot machine cannot use dozens of sheet-shaped goldingot paper, and is ingenious in design, high in stability and good in use effect.

Owner:潍坊合一机械有限公司

Mixed type printing system

InactiveCN112455087AImprove feeding effectUniform loadRotary pressesPrinting press partsProcess engineeringMechanical engineering

The invention discloses a mixed type printing system which comprises a machine body. A printing roller, a pressing roller and a guide roller are sequentially installed in the machine body from left toright, and mixing assemblies are arranged in a box body and below the box body. According to the mixed type printing system, the feeding effect on the printing roller can be greatly improved throughcooperation with spray heads distributed at equal intervals, the feeding amount is more uniform, then the printing quality is guaranteed, meanwhile, through rotary connection of a vertical rod and thebox body and arrangement of stirring blades, materials in multiple material injection cylinders can be rapidly mixed in the box body and put into use, the use instantaneity is improved, the materialscan be continuously stirred, accidental condensation of the materials is avoided, the feeding stability is improved, a double-sided drying effect can be achieved on printed finished products, the inking effect is further guaranteed, cross blooming can be avoided, the hot air spraying range is enlarged, the hot air diffusion uniformity is improved, the printing efficiency is further improved, thedrying effect is improved, and people can use the system conveniently.

Owner:宋忠银

Chemical liquid reaction kettle capable of uniformly conveying materials

The invention discloses a chemical liquid reaction kettle capable of uniformly conveying materials. The chemical liquid reaction kettle comprises a reaction kettle and a transmission box, wherein theleft and right sides of the transmission box are respectively provided with a material conveying mechanism, and the bottom ends of the material conveying mechanisms at the left and right sides are respectively provided a first material conveying box and a second material conveying box; a drive motor is mounted on the rear side of the transmission box; a gearbox is mounted on the front end of the drive motor; a transmission shaft is mounted on the front end of the gearbox; the front end of the transmission shaft is provided with a transmission gear; the upper and lower ends of the transmissiongear are respectively provided with a first driven gear and a second driven gear; the first driven gear and the second driven gear are engaged with the transmission gear; the front ends of the first driven gear and the second driven gear are respectively provided with a first notched gear and a second notched gear; and a movable frame is arranged between the material conveying mechanisms located at the left and right sides the invention is adjustable The chemical liquid reaction kettle provided by the invention can adjust a feeding rate and effectively control the progress of a reaction, and is applicable to operation of high-quality chemical products.

Owner:朱园园

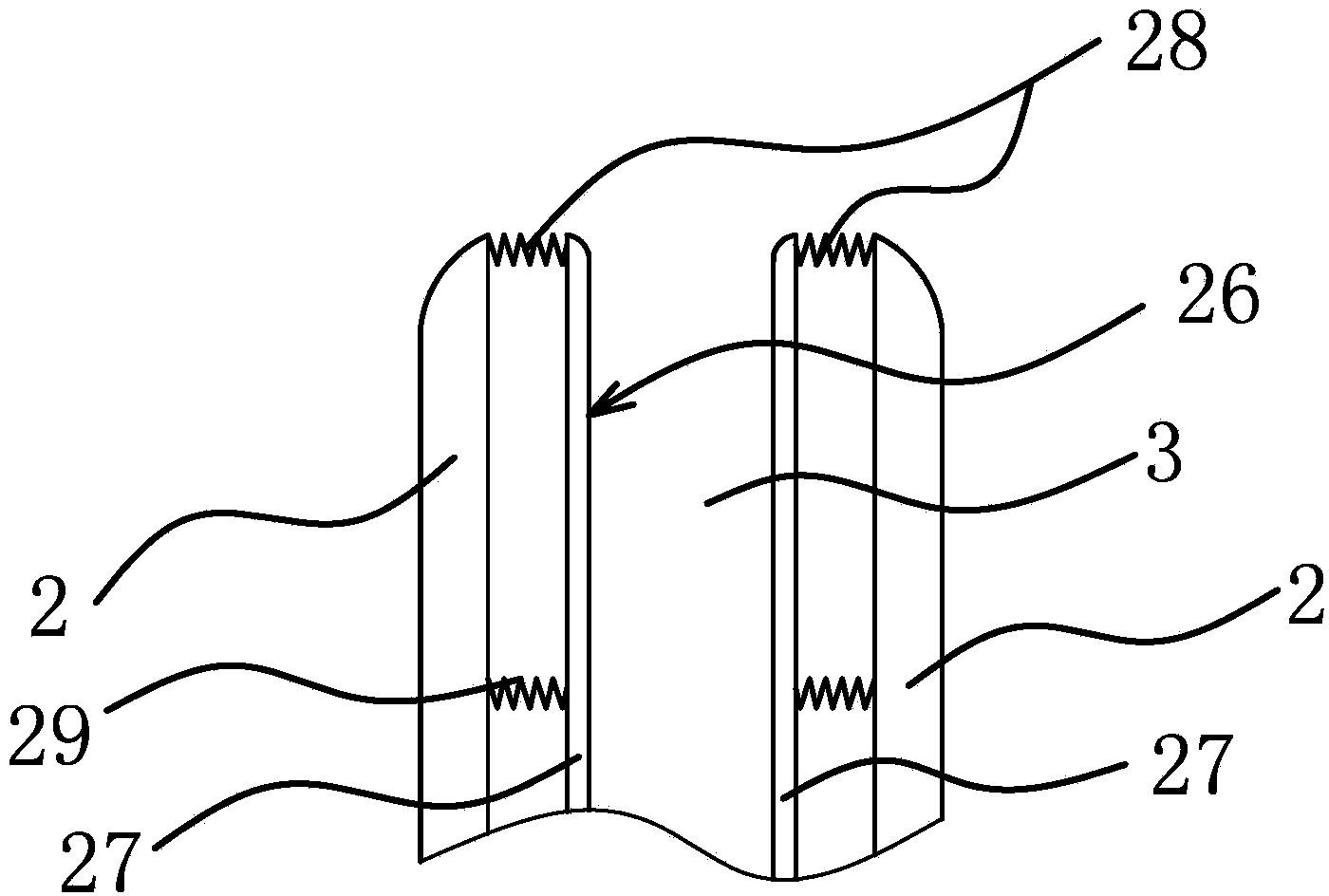

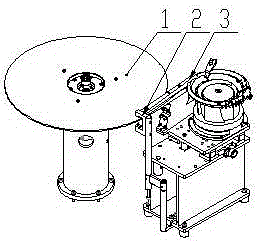

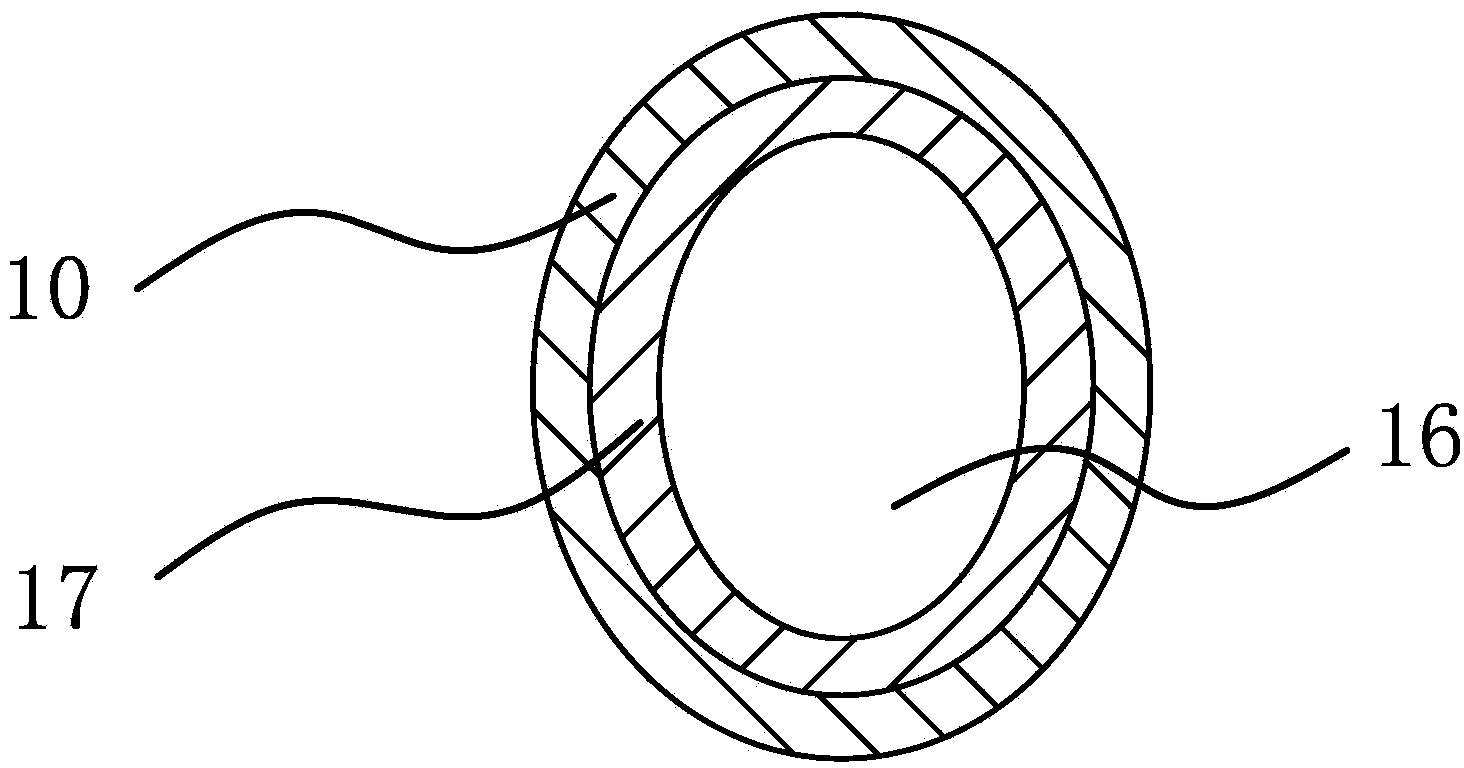

Special powder conveying device for powder forming machine and work process of special powder conveying device

The invention provides a special powder conveying device for a powder forming machine and a work process of the special powder conveying device. The special powder conveying device comprises a template (2), wherein a powder conveyor (13) which leftwards and rightwards moves along the template (2) is arranged on the template (2), a hopper (17) corresponding to the powder conveyor (13) is arranged on the powder conveyor (13), the hopper (17) is stationary, the upper part and the lower part of the powder conveyor (13) are in split arrangement, and the upper part of the powder conveyor (13) can realize vertical upward and downward movement, so that the upper surface of the upper part of the powder conveyor (13) can be tightly abutted against the first lower surface of the hopper (17). The special powder conveying device has the advantages that the hopper does not swing along with the moving of the powder conveyor, so that the characteristics of the metal powder maintain the stable state, the product quality is greatly improved, and further product quality influence caused by a metal powder segregation phenomenon due to forward and back vibration and swinging of the hopper of the original air cylinder compression material conveying mechanism is avoided.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

Stamping device and stamping method thereof

A stamping device and a stamping method thereof are disclosed. The stamping method is performed using the stamping device. The stamping device comprises a first die holder having a feeding guide groove extending along a feeding direction and a die orifice; a second die holder, provided on one side of the first die holder and having a punch corresponding to the die orifice; and a variable guide assembly having a positioning block which is slidably coupled to the first die holder along the feeding direction. By the structure, it is possible to produce a finished product having a different size in a single dimension, thereby reducing the manufacturing cost.

Owner:METAL INDS RES & DEV CENT

Push rod type dividing device

InactiveCN106743510ARealize split feedingAchieve countConveyorsControl devices for conveyorsEngineeringPiston rod

The invention provides a push rod type dividing device, and belongs to the technical field of feeding machines. The push rod type dividing device comprises a feeding material way, a detecting probe, fixed baffles, a movable baffle, a diving material way, a connecting plate, a pushing rod and a lever. The fixed baffles are arranged at the right end of the feeding material way at equal intervals, the movable baffle is arranged on a sliding support in a vertically-sliding manner, insertion sheet stopping blocks are arranged at the lower end of the movable baffle, and the insertion sheet stopping blocks and the fixed baffles are arranged at intervals; the diving material way is arranged on one side of the feeding material way, the detecting probe is installed on the feeding material way, and the connecting plate is arranged on a support guide rail in a front-and-back sliding manner; a piston rod of a driving air cylinder is connected with the connecting plate, the push rod is installed on the connecting plate, and the middle end of the lever is hinged to a rack through a bearing pin shaft; and a first support lug is inserted into a U-shaped groove in the lower end of the lever, and the other end of the lever is attached to the lower end of a second support lug of the movable baffle. By means of the push rod type dividing device, workpieces in the feeding material way are divided into three or more branch material ways, the structure is reasonable and small, cost is low, and the feeding stability is good.

Owner:TONGXIANG GREENCITY FLOCKING

Accurate feeding equipment

ActiveCN112875228AReduce material overlapImprove feeding efficiencyLoading/unloadingConveyor partsLinear vibrationElectrical and Electronics engineering

The invention relates to the technical field of material conveying, in particular to accurate feeding equipment. The equipment comprises a feeding hopper, a first feeding mechanism, a second feeding mechanism, a flattening mechanism, a counting device and a quantifying hopper, wherein the feeding hopper is located above the first feeding mechanism; the second feeding mechanism is located above the second feeding mechanism; the flattening mechanism is arranged on the first feeding mechanism; the second feeding mechanism comprises a second material rail, a first linear vibration feeder, a second linear vibration feeder and a second base; the second material rail is provided with a rapid material channel and a fine supplementing material channel; the first linear vibration feeder and the second linear vibration feeder abut against the rapid material channel and the fine supplementing material channel respectively; the counting area of the counting device is located below the second feeding mechanism; and the quantifying funnel is exposed out of the counting area of the counting device. According to the accurate feeding equipment, the materials can be effectively dispersed, the counting device can conveniently calculate the number of the materials, double-channel feeding is achieved, the feeding efficiency is high, and the materials can be accurately and quantitatively output.

Owner:东莞市安翔智能包装设备有限公司

Conveying device of tufting embroidering machine

PendingCN109537201AImprove embroidery qualityPrecise positioningFeedersDegrees of freedomEngineering

The invention discloses a conveying device of a tufting embroidering machine. The device comprises a conveying part for conveying base blanket cloth to the lower part of the tufting embroidering machine for embroidering, a positioning part which is positioned below the tufting embroidering machine and is used for fixing and tensioning the base blanket cloth, and a collecting part for collecting the embroidered blanket cloth, wherein a discharging end of the conveying part and a feeding end of the collecting part are correspondingly provided with positioning mechanisms for fixing and releasingthe base blanket cloth; correcting mechanisms for correcting skewed base blanket cloth are arranged below the positioning mechanisms. According to the device, the conveying part, the positioning partand the collecting part are matched to realize automatic conveying of the tufting embroidering machine, so that the tufting embroidering efficiency is improved; a plurality of sets of positioning mechanisms are matched to effectively limit the degree of freedom, to be limited during tufting embroidering, of the base blanket cloth, so that the coaxiality in tufting embroidering can be greatly controlled, and the stability of surface tension of the base blanket cloth can also be greatly controlled; and the two sets of correcting mechanisms are matched to correct the skewed base blanket cloth, sothat the embroidering quality is improved.

Owner:JINHUA JIELING HOUSE WARES CO LTD

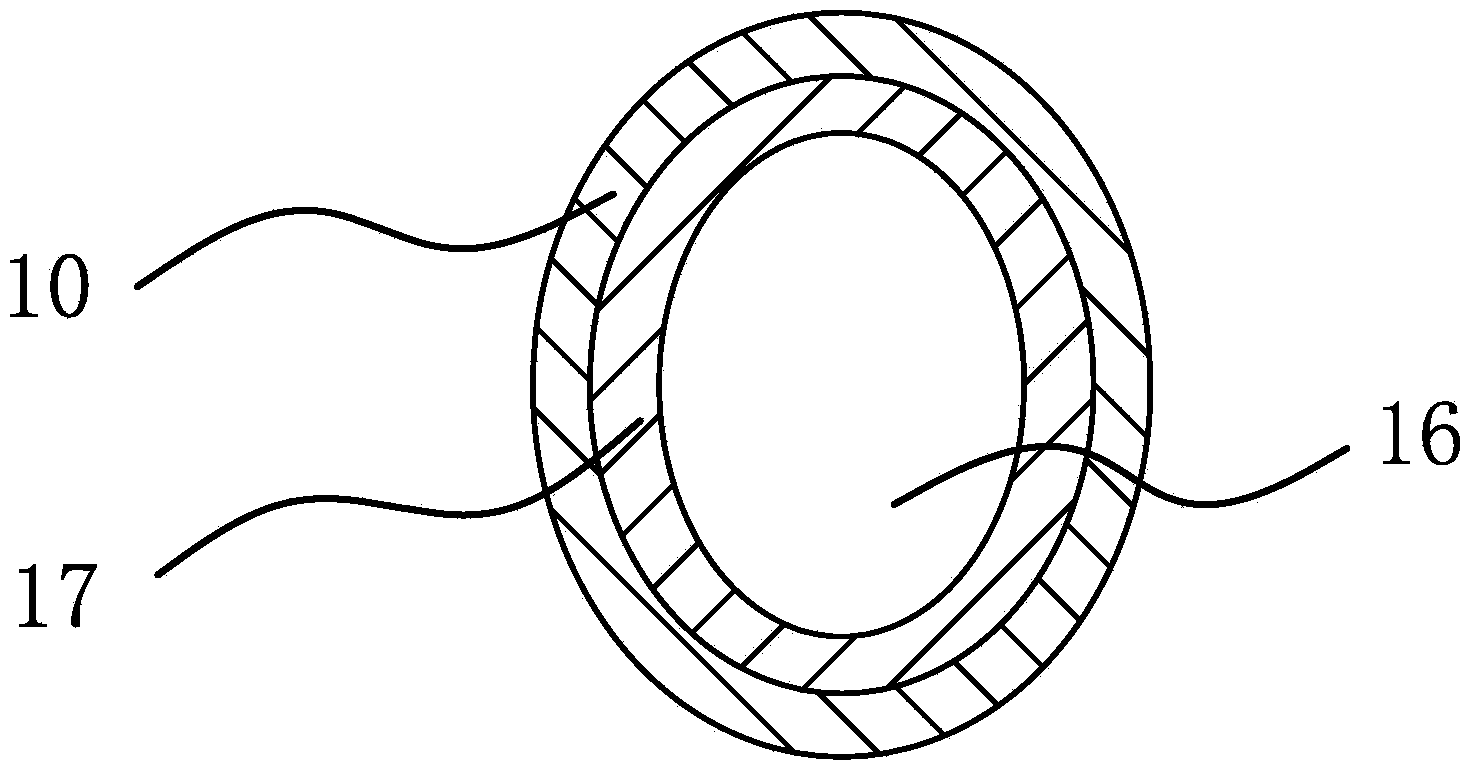

Push rod type feeding device

InactiveCN106975973AReasonable structureGood feeding stabilityMetal working apparatusEngineeringMachining

The invention provides a push rod type feeding device, which belongs to the technical field of mechanical processing. It includes a fixed material channel, an openable material channel, a return spring, a first wedge block, a second wedge block, and a push rod cylinder. The fixed material channel is fixed on the frame. The upper end of the opening and closing material channel is hinged on the frame through the supporting pin, and is located directly below the fixed material channel. The inner side of the openable and closing material channel is also provided with a guide groove. The ring workpiece can slide up and down on the guide groove. The first wedge and the second wedge are symmetrically arranged on both sides of the lower end of the openable and closed material channel. One spring strut, the other end is connected to the second spring strut. The invention realizes intermittent feeding of ring workpieces, has reasonable structure and good feeding stability.

Owner:徐晓伟

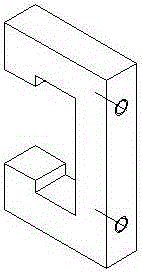

Magnetic correcting mechanism for workpiece posture

InactiveCN105149236AEasy to adjustImprove feeding stabilityConveyorsSortingEngineeringMechanical engineering

The invention discloses a magnetic correcting mechanism for workpiece posture. The magnetic correcting mechanism for the workpiece posture is used for a visual detecting device. The mechanism is composed of a C-shaped magnet installing base, a magnet, a magnet protective cover and an adjustable support. According to the mechanism, due to the fact the workpiece posture is corrected in the feeding procedure through magnetic force, feeding stability, the posture accuracy rate and the feeding speed are optimized.

Owner:北京昊达防务科技有限公司

Sock head sewing device with air power source

The invention provides a sock head sewing device with an air power source, belonging to the technical field of textile machinery. The sock head sewing device solves the technical problem that the surfaces of socks cannot be automatically turned over after the heads of the socks are sewn. The sock head sewing device with the air power source comprises a rack, a sock discharging end is the right end of the rack, the rubber magnetic sheets I and rubber magnetic sheets II are arranged at the bottom ends of the socks, a discharging opening allowing the socks to penetrate through is formed in the bottom of a sock guide barrel, an electromagnet is further fixed to the bottom of the sock guide barrel, an air cylinder is fixed to the right end of the rack, a cylinder body of the air cylinder is fixed on the rack, a telescopic arm is fixedly connected to the lower end of a piston rod, a material storage basket is just under the telescopic arm and is fixed onto the material storage base, and the telescopic arm can be inserted into the material storage barrel and pushes the socks to fall into the material storage basket. The surfaces of the socks can be automatically turned over after the heads of the socks are sewn, accordingly, the production efficiency of socks is high.

Owner:HAINING SUNSHINE SOCKS MFG

Automatic feeding device of rod material automatic conveying machine

The invention belongs to the technical field of mechanical material automatic conveying in machining and particularly relates to an automatic feeding device of the rod material automatic conveying machine. The automatic feeding device comprises a material storage mechanism which is arranged on one side of a machine frame and is placed below a material conveying mechanism on the machine frame. A material lifting mechanism which can lift rod materials placed in the material storage mechanism one by one horizontally and place the rod materials in the material conveying mechanism is arranged between the material storage mechanism and the machine frame. The material lifting mechanism is connected with a rod material conveying detecting mechanism arranged at the material conveying mechanism and can move according to signals collected by the rod material conveying detecting mechanism. Compared with the prior art, the automatic feeding device of the rod material automatic conveying machine has the advantages of being reasonable in design, simple in structure and good in feeding stability, the rod materials cannot be separated easily, the rod materials can be supplied according to needs, and the device and other equipment operate in a coordinating mode.

Owner:盐城福万家保温板有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com