Clamping edge-type feeding device

A feeding device and clip-blade technology, which is applied in the field of clip-blade feeding device, can solve the problems such as difficulty and complexity in the control of width and thickness dimensional accuracy, plate shape and surface quality, complex and huge rolling mill equipment, and easy movement of plates. , to achieve the effect of simple structure, good feeding stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

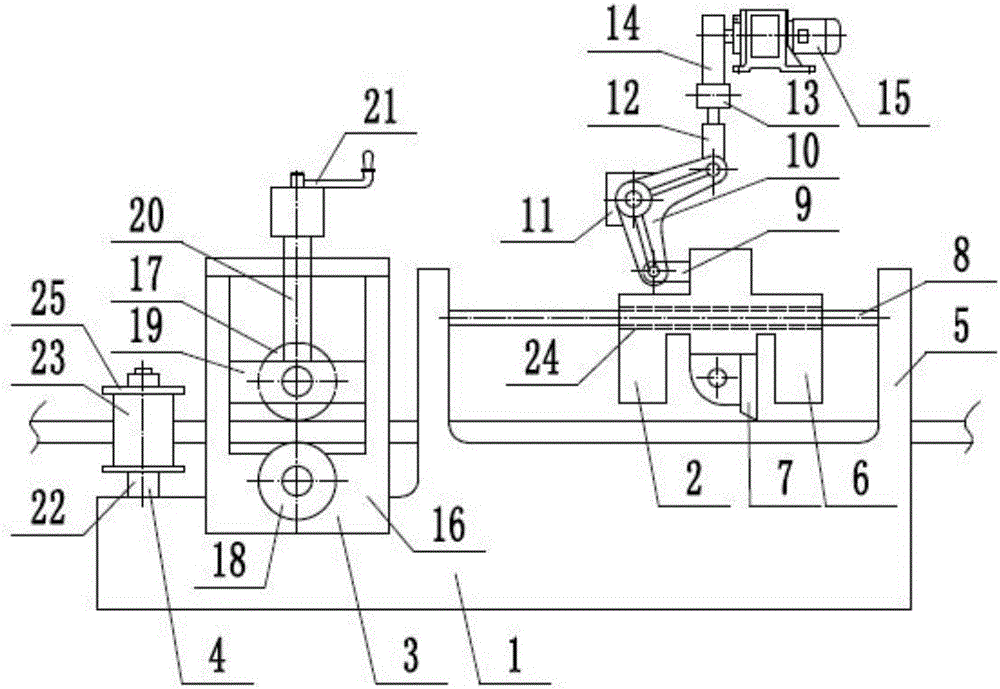

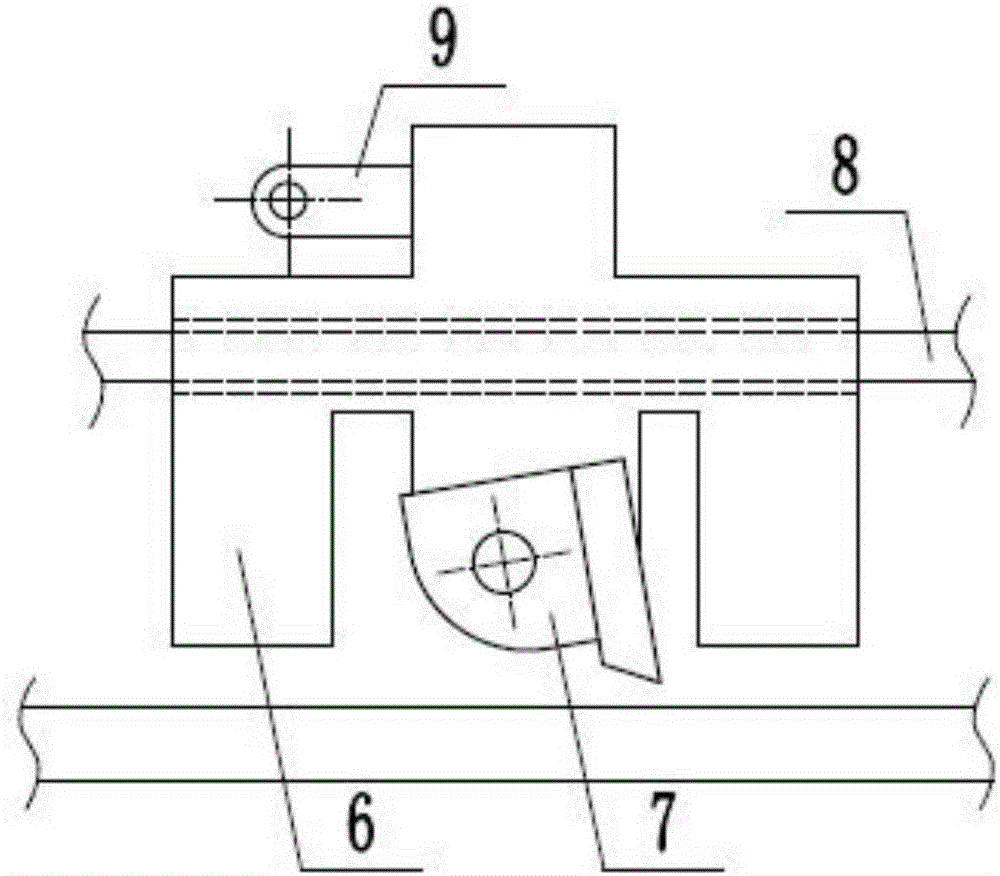

[0013] Such as figure 1 and figure 2 As shown, a clamping blade type feeding device includes a frame 1, a feeding mechanism 2, a longitudinal guiding mechanism 3, and a transverse guiding mechanism 4. The feeding mechanism 2 realizes intermittent feeding of plates, and the longitudinal guiding mechanism 3 realizes the For the longitudinal guidance of the plate, the transverse guide mechanism 4 realizes the transverse guidance of the plate. Described feeding mechanism 2 comprises supporting bracket 5, feeding bearing 6, feeding clip knife 7, guide rod 8, connecting bracket 9, lever 10, lever bracket 11, pull bar 12, supporting roller 13, cam 14, driving motor 15, all The support bracket 5 is fixed on the upper sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com