Magnetic correcting mechanism for workpiece posture

A technology for correcting mechanisms and workpieces, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as bottlenecks in the feeding process, inability to ensure stable transportation, and inability to efficiently screen correct postures for several types of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

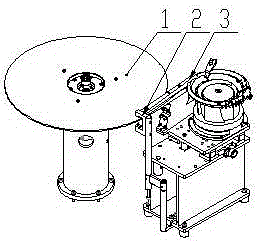

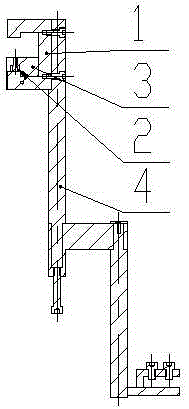

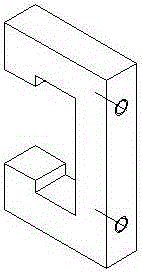

[0012] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] The mechanical structure of the present invention includes: 1. C-type magnet mounting base 2, magnet 3, magnet shield 4 adjustable support;

[0014] The magnet and the C-shaped magnet mounting base form a magnetic flux circuit, wherein the magnetic field is in a vertical direction. When the magnetic material workpiece passes through the magnetic field, the posture of the workpiece is corrected under the action of the magnetic field force.

[0015] The C-shaped magnet mount acts as a fixed support, and the magnet is adsorbed on the C-shaped magnet mount. The magnet shield covers the magnet, reducing the risk of workpieces falling onto the magnet and becoming magnetized. The C-shaped magnet mounting base is installed on an adjustable bracket, providing three adjustment degrees of freedom of X, Y, and Z. The horizontal X, Y degrees of fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com