Shoe-shaped gold ingot machine and paper folding process

A technology of ingot machine and ingot, which is applied in the field of paper printing or origami, which can solve the problems of poor positioning accuracy and unusability of sheet-shaped ingot paper, and achieve the effect of reducing the cost of research and development investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

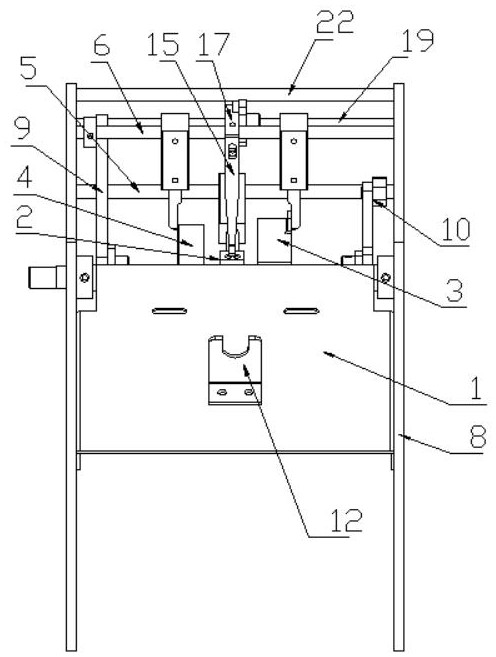

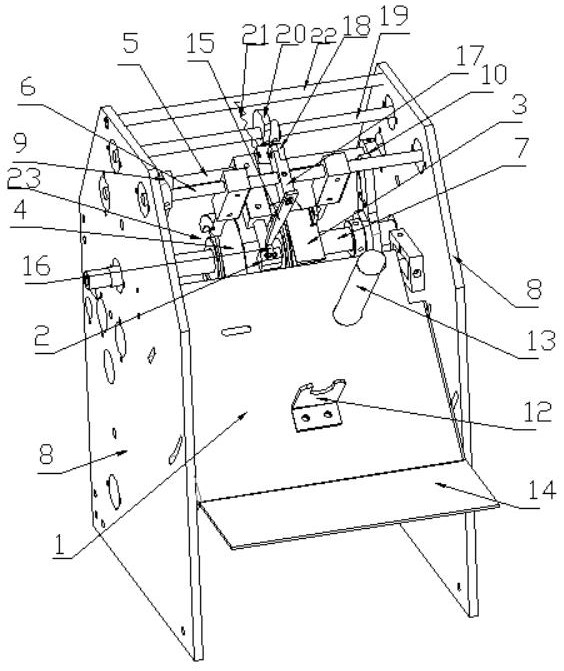

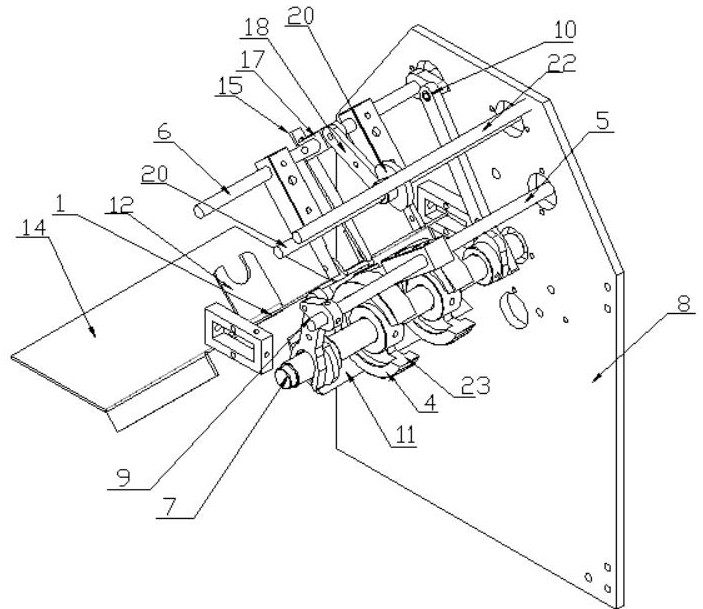

[0048] For the convenience of explanation, the following is combined with the Figure 1-20 , explain in detail the invented ingot machine and origami craft.

[0049] An ingot machine, comprising a feeding system A, a pre-folding conveying system B, a folding system C, and a stacking system D.

[0050] The feeding system includes a silo, the silo includes a bottom plate 1 with an inclined bottom, and a feed assembly assembly is provided on the top of the silo, and the feed assembly assembly includes a swingable negative pressure suction nozzle 2 , the claw 3 that can be inserted between the last piece of ingot paper and dozens of ingot papers, and the driving roller 4 that uses friction to slide the last piece of ingot paper out of the bottom of the bin when rotating, and the negative pressure suction nozzle 2 The shaft is connected to the first rotating shaft 5, the claw 3 is fixed on the second rotating shaft 6, the driving roller 4 is shafted on the third rotating shaft 7, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com