Novel filtering material performance testing device based on mask research and development

A filter material performance and testing device technology, applied in the direction of measuring devices, analysis materials, suspension and porous material analysis, etc., can solve the problems of simultaneous detection to compare the air permeability of filter materials, and the inability to detect mask filter materials, so as to reduce research and development Input cost, good test effect, shorten cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

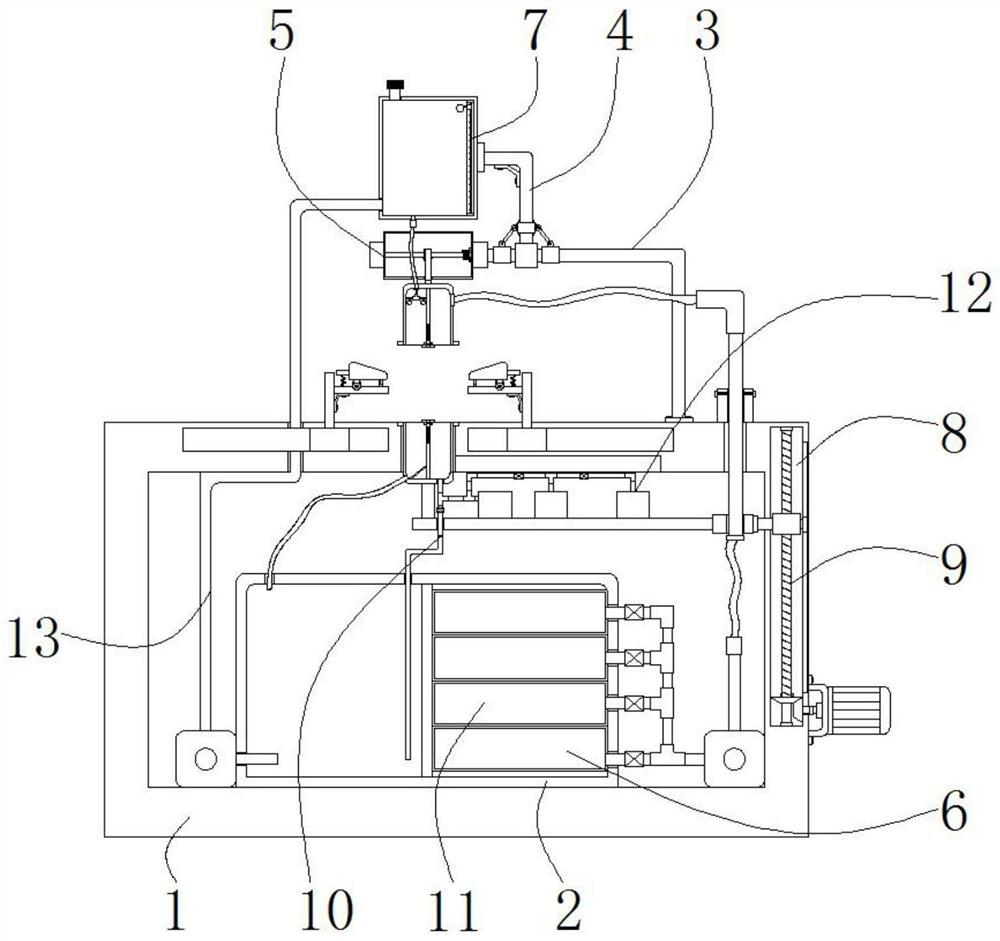

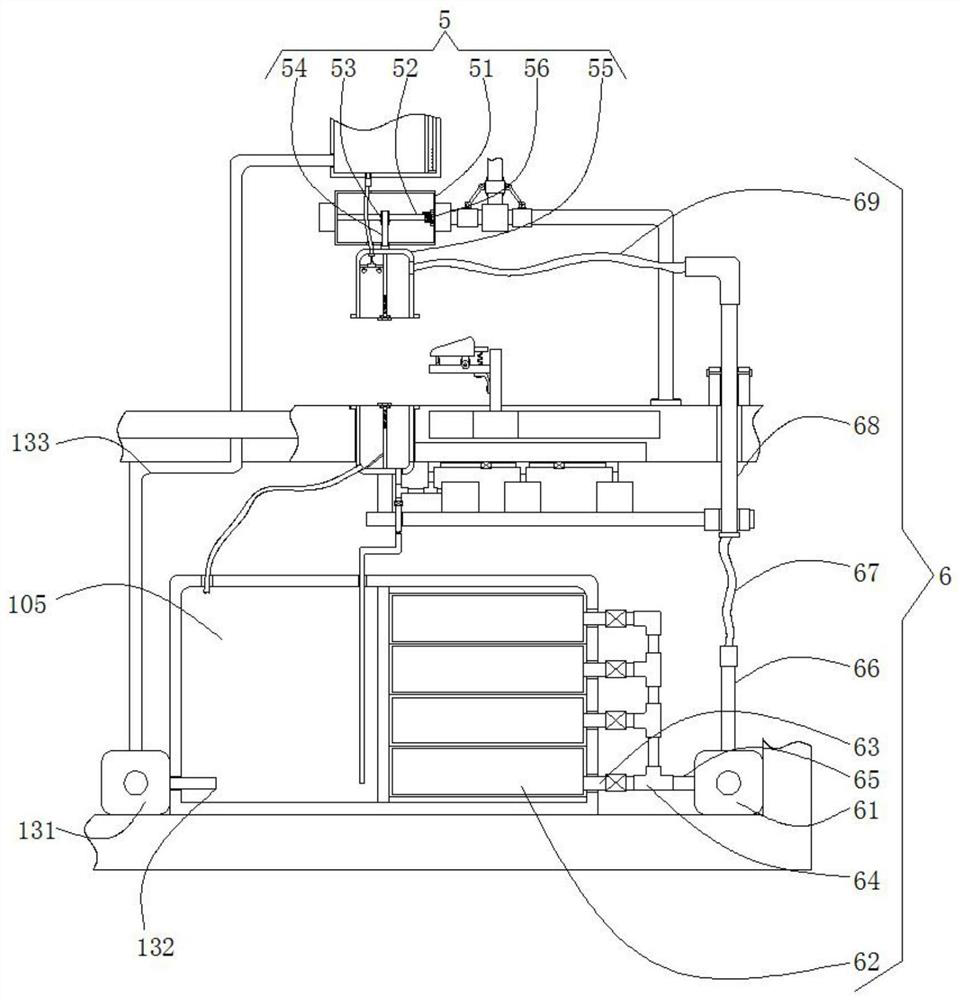

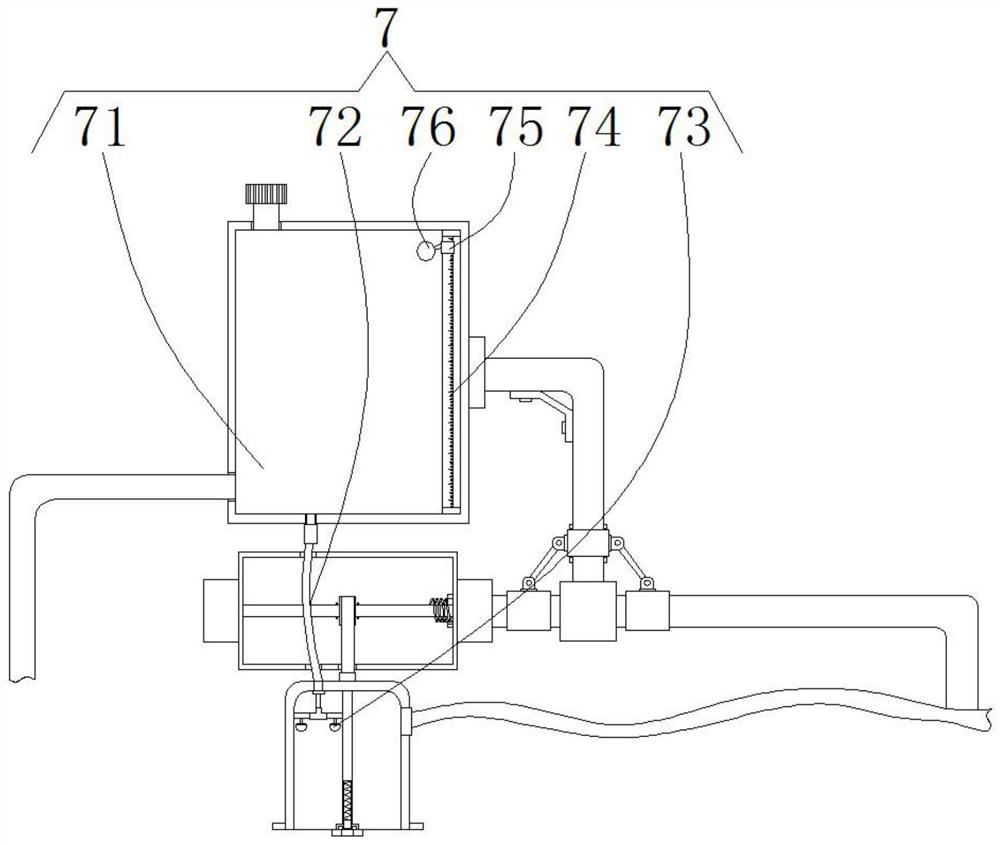

[0043] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 ,in, figure 1 The structural schematic diagram of the first embodiment of the new filter material performance testing device based on the research and development of the mask provided by the present invention; figure 2 for figure 1 Schematic diagram of the structure of the detection device shown; image 3 for figure 1 The schematic diagram of the structure of the moisture detection device shown; Figure 4 for figure 1 The structural schematic diagram of the lifting device shown; Figure 5 for figure 1 The schematic diagram of the structure of the lower detection device shown; Figure 6 for figure 1 Schematic diagram of the structure of the gas detection device shown; Figure 7 for figure 1 The structural schematic diagram of the conveying device shown; Figure 8 for figure 1 A schematic diagram of the external structure is shown. A new type ...

no. 2 example

[0080] Please refer to Figure 9 and Figure 10 , based on the new filter material performance testing device developed based on the mask provided in the first embodiment of the application, the second embodiment of the application proposes another new filter material performance test device based on the mask research and development. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0081] Specifically, the difference between the new filter material performance test device developed based on the mask provided by the second embodiment of the present application is that a new filter material performance test device based on the mask research and development, the top of the inner wall of the detection platform 1 is provided with The clamping device 14, the clamping device 14 includes two movable slots 141, the inside of the two movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com