Powder packaging robot intelligent bagging system

A technology of intelligent bagging and robotics, applied in packaging, transportation packaging, transportation and packaging, etc., to achieve the effect of improving work efficiency, increasing work life, and reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

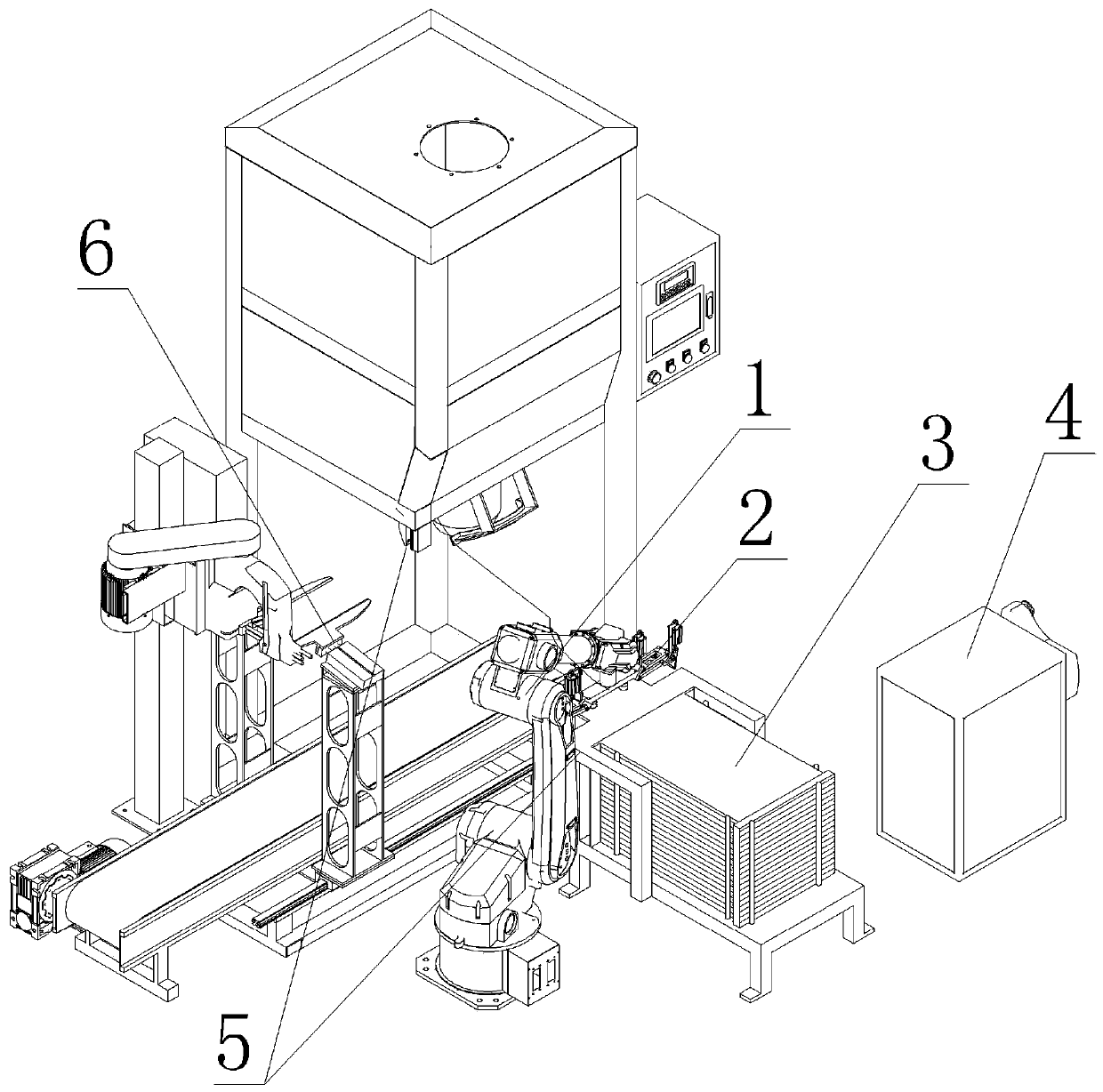

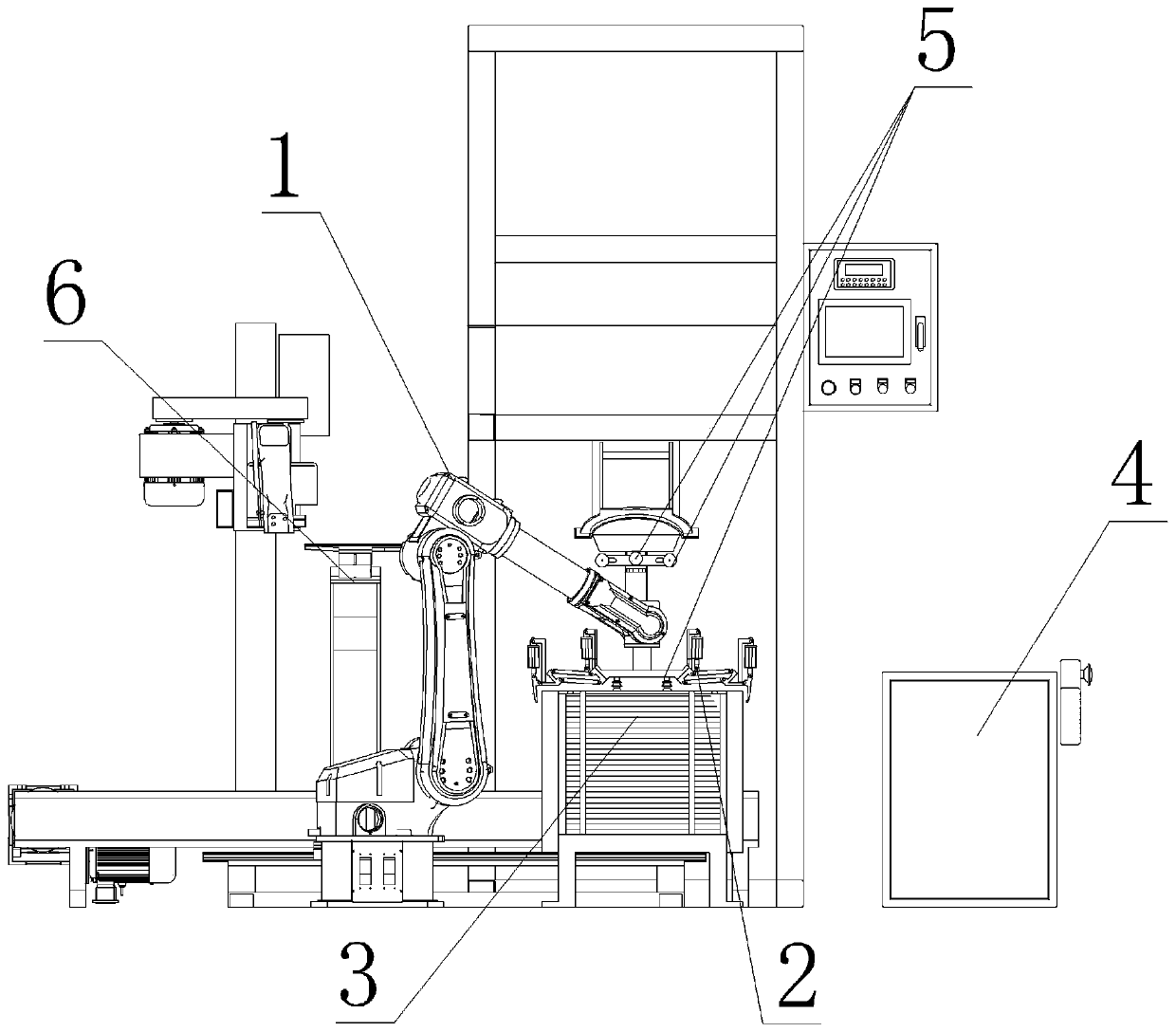

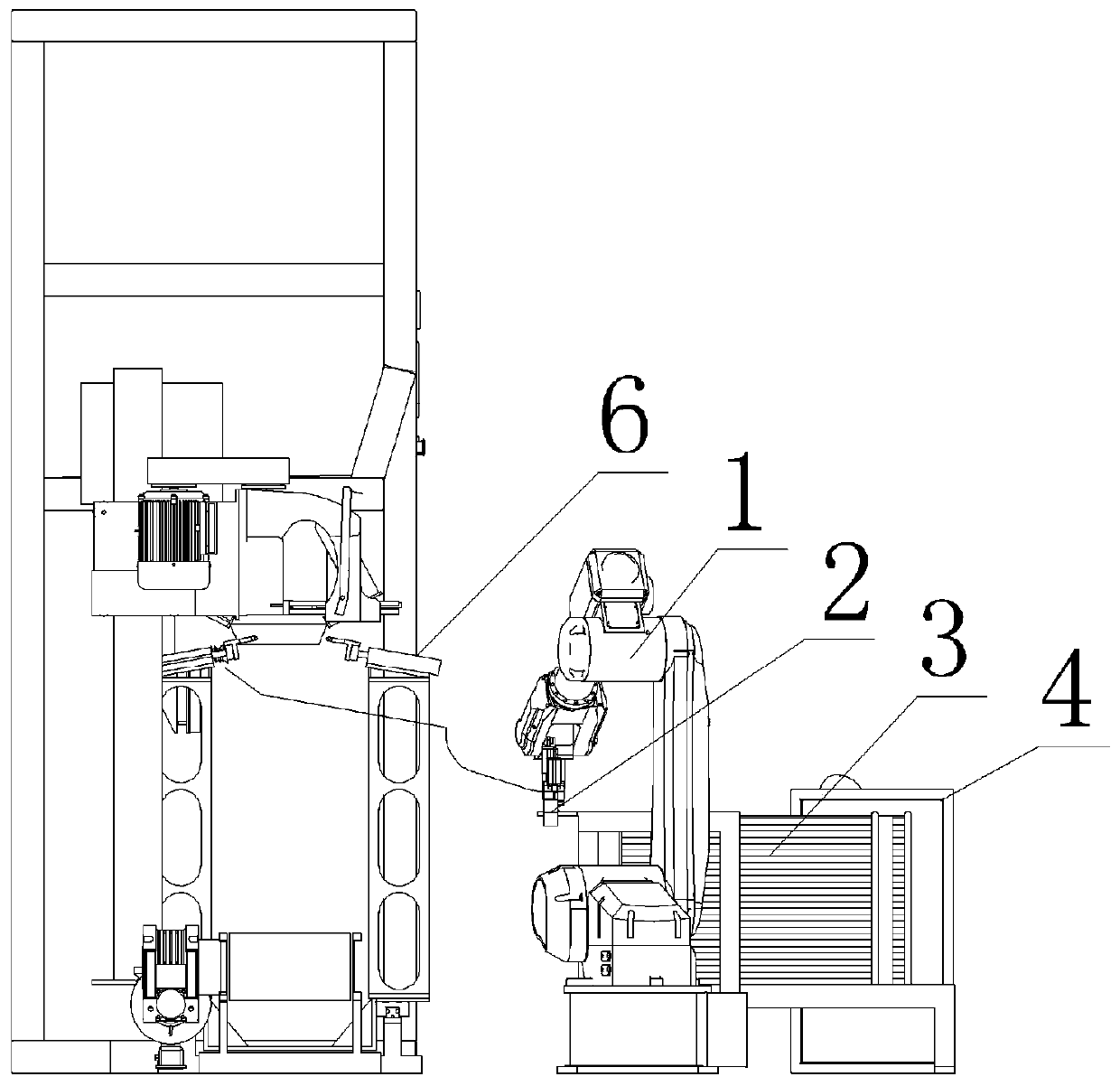

[0027] Powder packaging robot intelligent bagging system is suitable for 10kg-50kg general-purpose powder packaging machine with a round discharge port equipment, robot automatic bagging equipment, the robot intelligent bagging system consists of the following parts:

[0028] (1) The six-axis industrial robot body 1 includes six axes, and the six axes are respectively connected to the corresponding six-axis servo motors. The sixth axis is equipped with a grasping manipulator mechanism. The six-axis industrial robot is controlled by a Completed by computer, its controller is responsible for system management, communication, kinematics and dynamics calculation, and sends instruction information to the six-axis servo motor control module, and the distributed corresponding control of the six axes is used for interpolation calculation and servo Control processing, realize the given motion, and feedback information to the controller; the main features of the six-axis industrial robot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com