Clinging arm horizontal packing machine

An arm-splitting and horizontal technology, applied in the field of arm-scraping horizontal balers, can solve the problems of low compression efficiency, low production efficiency, and low packaging cost of forming bales, and achieve long service life, increased efficiency, and environmental requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

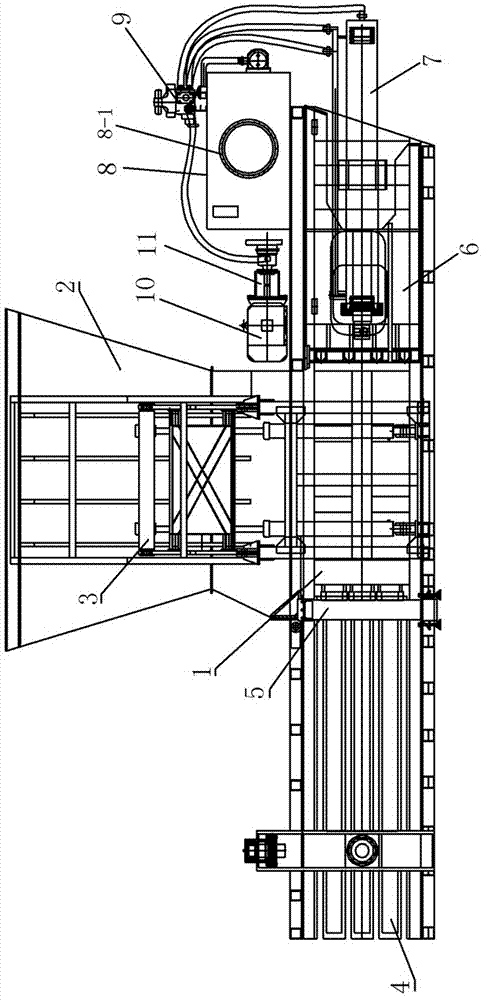

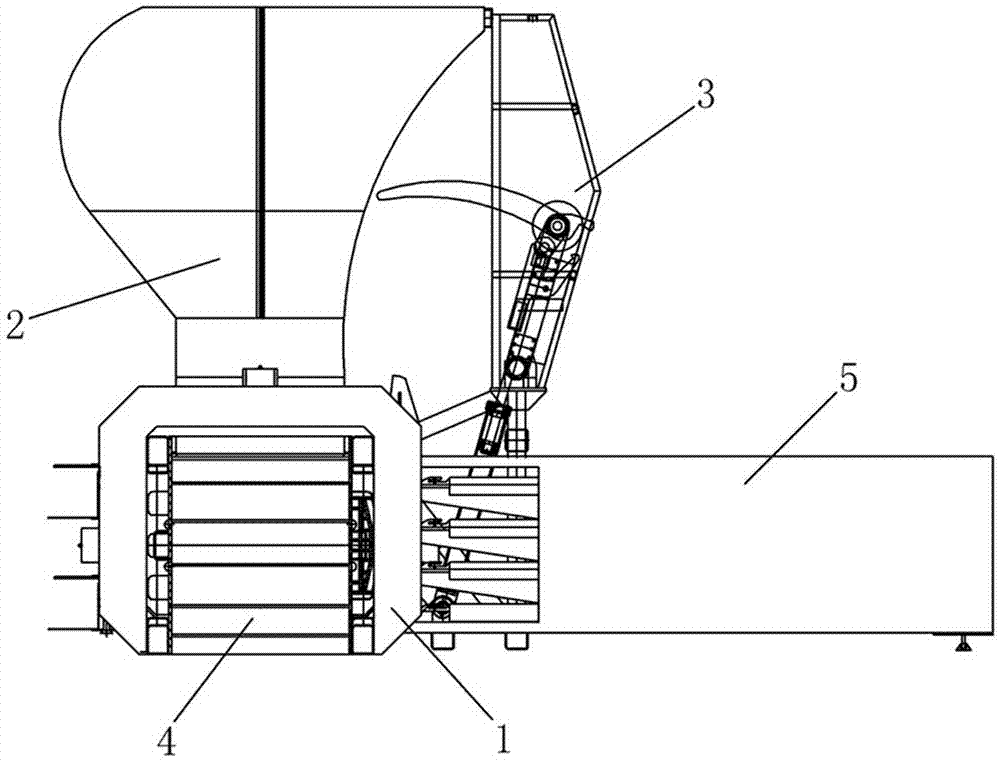

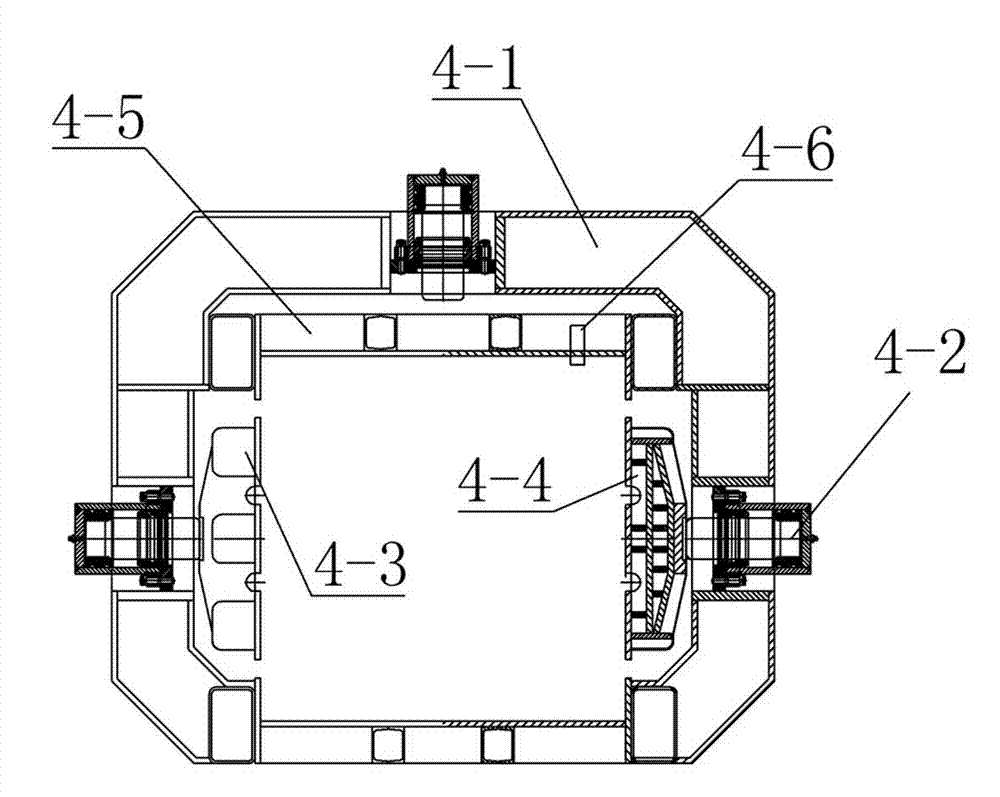

[0046] see Figure 1~Figure 20As shown, the meanings represented by the symbols in the figure are: 1. Chassis, 2. Hopper, 3. Pulling arm mechanism, 4. Clamping arm mechanism, 5. Hook rope device, 6. Push plate, 7. Main oil cylinder, 8. Oil tank, 9. Hydraulic components, 10. Motor, 11. Oil pump, 1-2. The first tool, 1-3. Anti-rebound mechanism, 1-3-1. The first slope, 1-3-2. The first Inclined surface, 2-1. Upper hopper, 2-2. Lower hopper, 2-3. Grilling finger groove, 2-4. Reinforcement beam, 3-1. Support frame, 3-2. Rotating shaft, 3-3. Grilling arm Limbs, 3-4 finger, 3-5. finger shaft, 3-6. arm cylinder, 3-7. cylinder base, 3-8. base shaft, 3-9 arm cylinder piston rod, 3- 10. Pull ring, 3-11. Pull plate, 3-12. Lock mouth, 3-13. Self-hanging lock, 4-1. Clamp arm base, 4-2. Clamp arm cylinder, 4-3. Blade, 4-4. Blade seat, 4-5. Upper clamp arm, 4-6. Meter counter, 4-7. Blade shaft, 4-8. Blade sleeve, 5-1. Frame, 5-2. Fixed plate , 5-3. Foot, 5-4. Driving sprocket, 5-5. Driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com