Equipment and method for achieving shaft hole assembly

A shaft hole and equipment technology, applied in the application field of industrial robots, can solve problems such as uncontrollable contact force, easy jamming, damage, etc., and achieve the effect of improving assembly quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

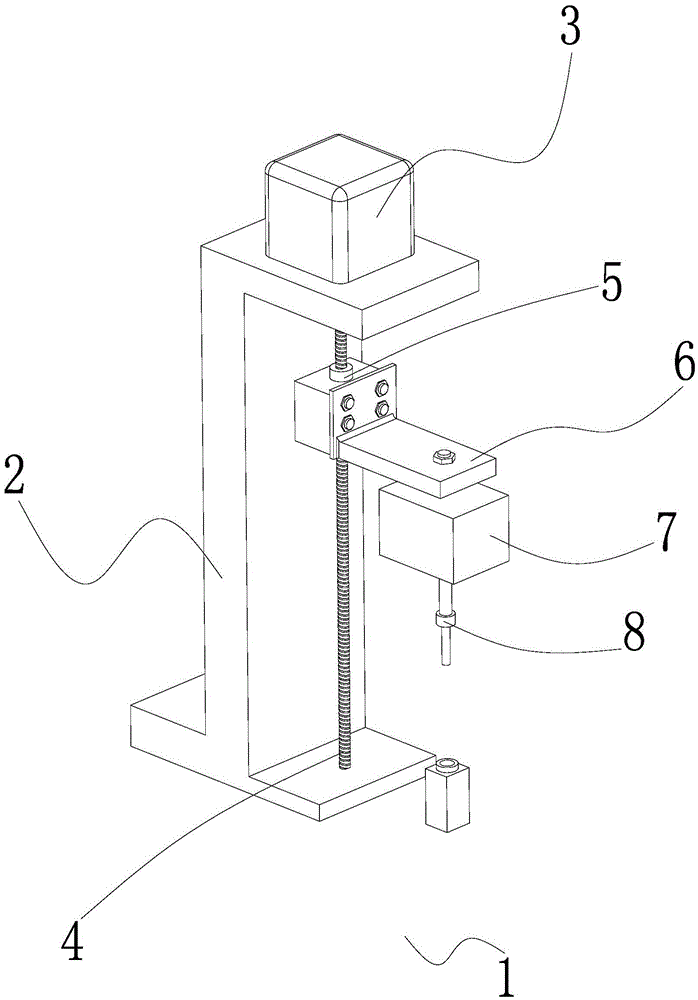

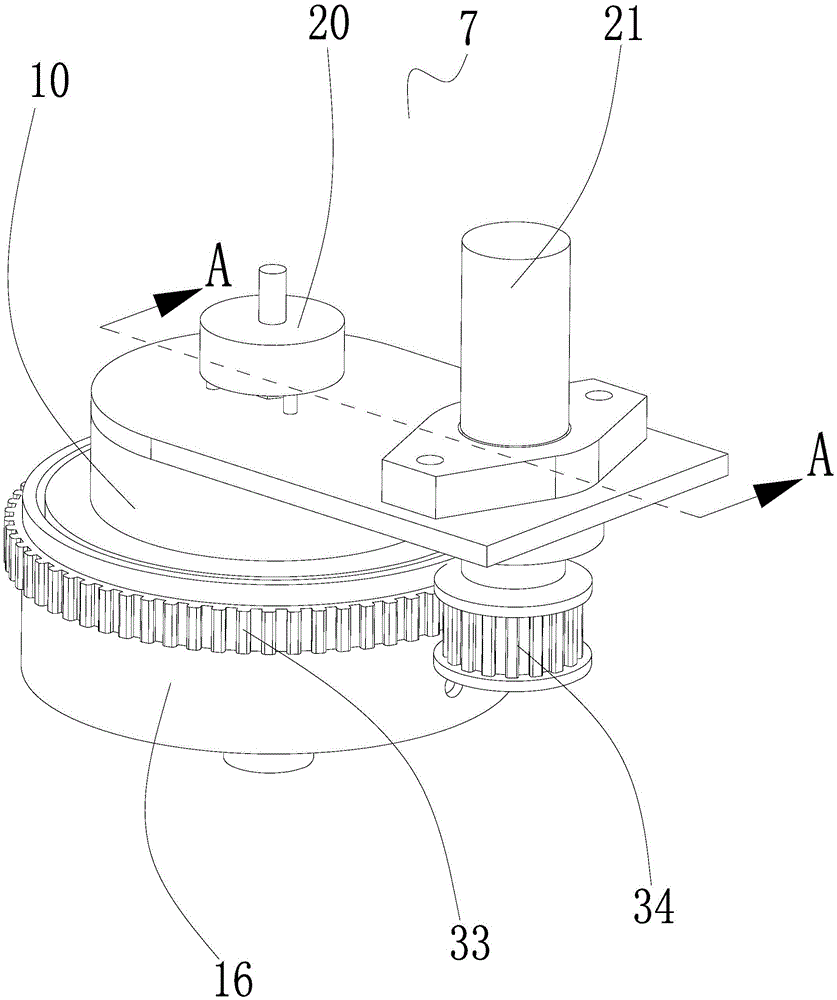

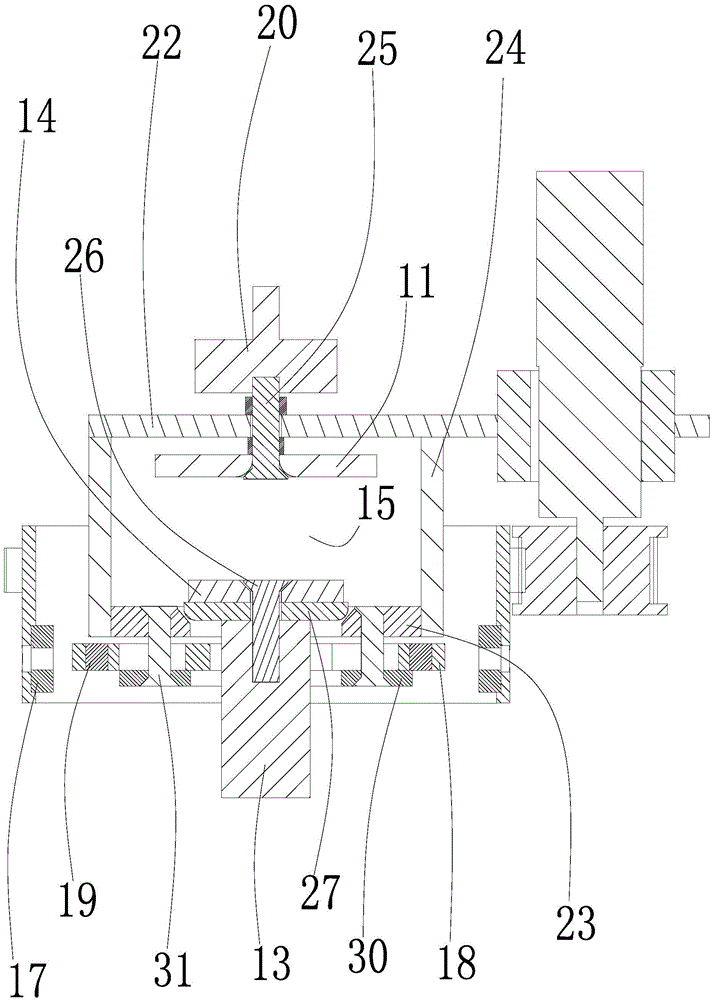

[0032] Please see attached figure 1 , a device 1 for shaft hole assembly, comprising a bracket 2 and a power unit 3 fixed on the bracket 2, the bracket 2 is provided with a screw 4 that can be driven and rotated by the power unit 3, the screw 4 extends from the upper end of the bracket 2 to the lower end of the bracket 2, the screw nut 5 is set on the screw rod 4 and can move up and down along it, and a connecting plate 6 is arranged on one side of the screw nut 5, the The connecting plate 6 is provided with a compliance device 7 based on magnetic field force to realize shaft hole assembly, and a clamping mechanism 8 connected to it is provided below the compliance device 7. When the screw rod 4 rotates under the drive of the power device 3, The screw nut 5 will move up and down along the screw rod 4, and at the same time drive the compliance device 7 connected with the screw nut 5 to move downward.

[0033] In the embodiment of the present invention, because the screw nut 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com