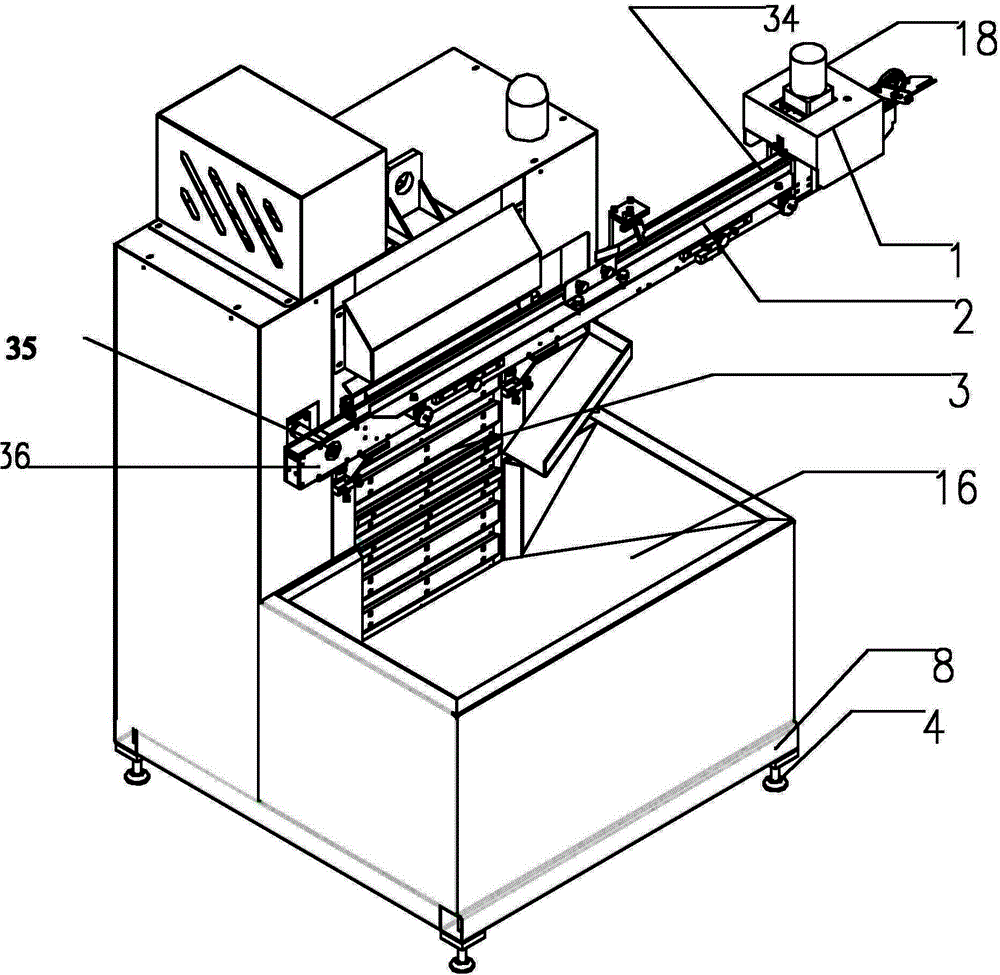

Lifting and oppositely clamping loader

A technology of feeding machine and feeding machine, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve the problems of easy material jamming and poor adaptability of bar materials, and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

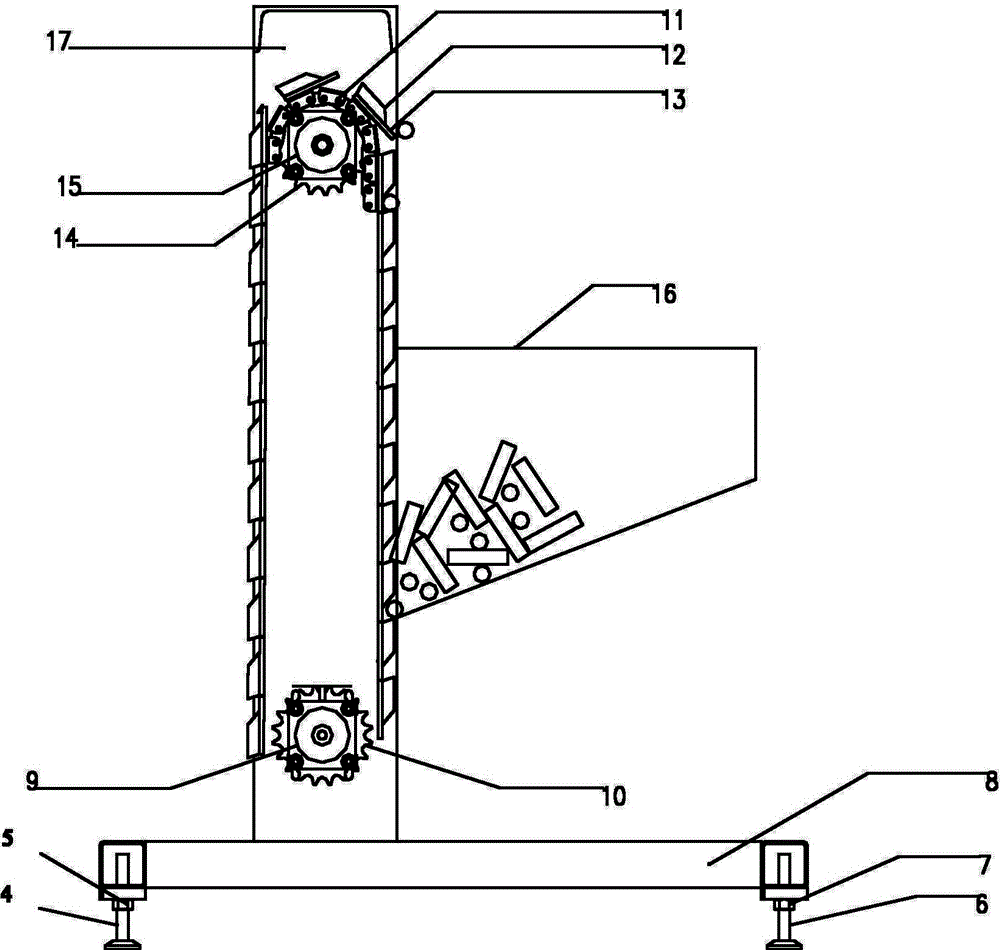

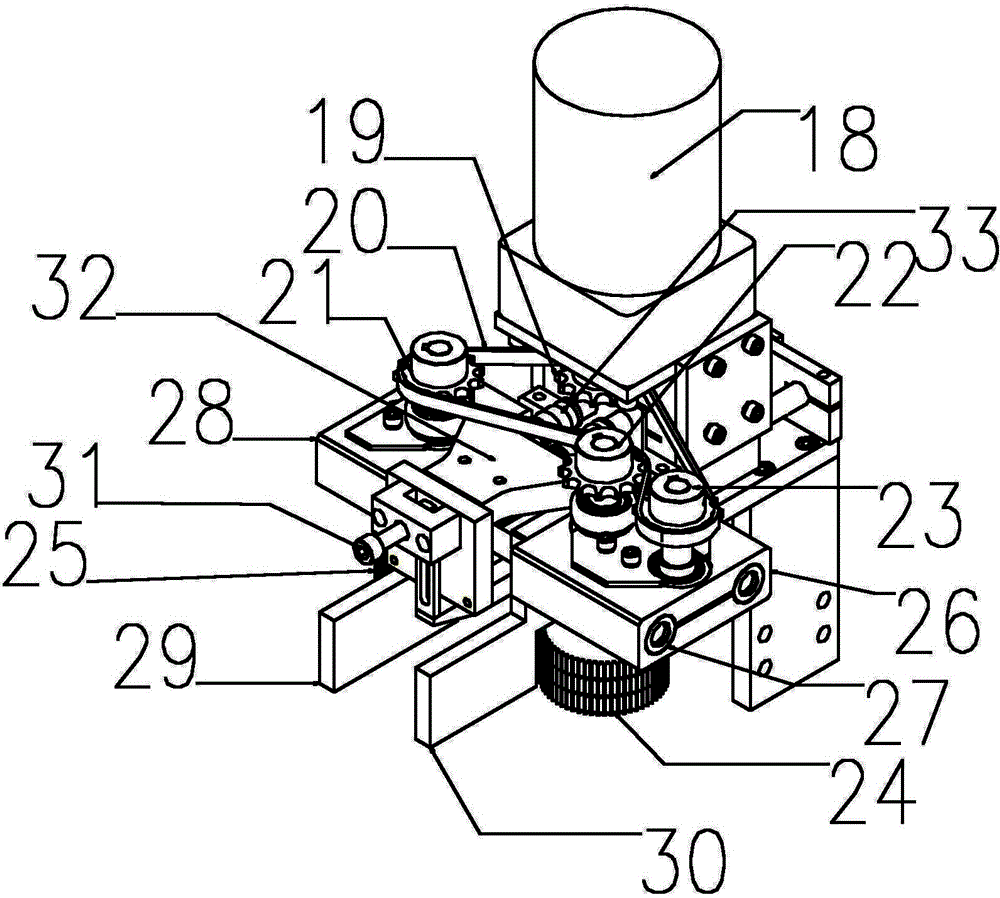

[0019] Scraper structure lifting bar process: the machine is supported by four feet that are the same as foot 4, and the height of the machine is adjusted through the foot nut 5. 8 is the machine base, the anchor nut 5 is connected with the base 8, and the main body 17 is fixed on the base 8. The upper end gear 14 is installed on the main body 17 by the upper end gear fixing part 15 through screws. Likewise, the lower end gear 10 is mounted on the main body 17 by the lower end gear fixing member 9 through screws. The chain 11 is attached to the upper gear 14 and the lower gear 10 . The upper and lower gears rotate to drive the chain 11 to rotate. The scraper fixing plate 13 is installed on the chain 11 , wherein the width of the scraper fixing plate 13 is the width of two chains 11 and the scraper fixing plate 13 is installed on the chain 11 at intervals rather than continuously. Squeegee 12 is installed on the scraper fixing plate. The magazine 16 is fixed on the main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com