Method and equipment for extracting fiber from stalks

A straw fiber and straw technology, which is applied in the field of plant fiber extraction, can solve the problems of grounding of air flights in traffic accidents, comprehensive utilization rate of less than 10%, large capital investment, etc., and achieves small capital investment, simple and convenient equipment, and equipment investment. The effect of the province

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1. extracts the method for rice straw fiber, comprises the steps:

[0041] (1) stock preparation, raw material is selected from the stalk of paddy rice;

[0042] (2) remove miscellaneous, the stalk of paddy rice is removed dust sundry;

[0043] (3) Cooking, putting the stalks into a cooking container with water for cooking;

[0044] (4) dehydration, dehydration of the cooked stalks, drying and dehydration with a centrifuge to a moisture content of 15%;

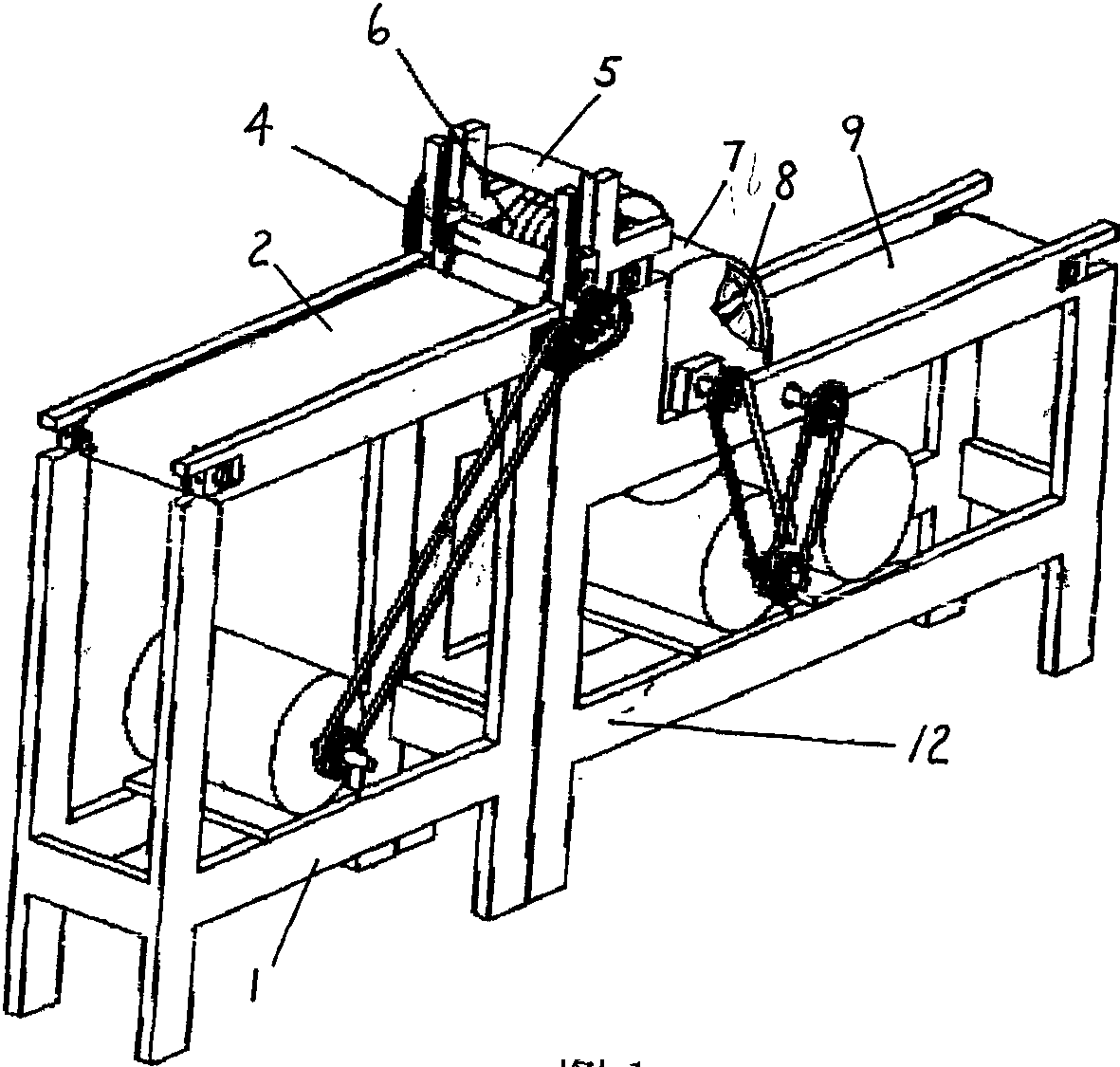

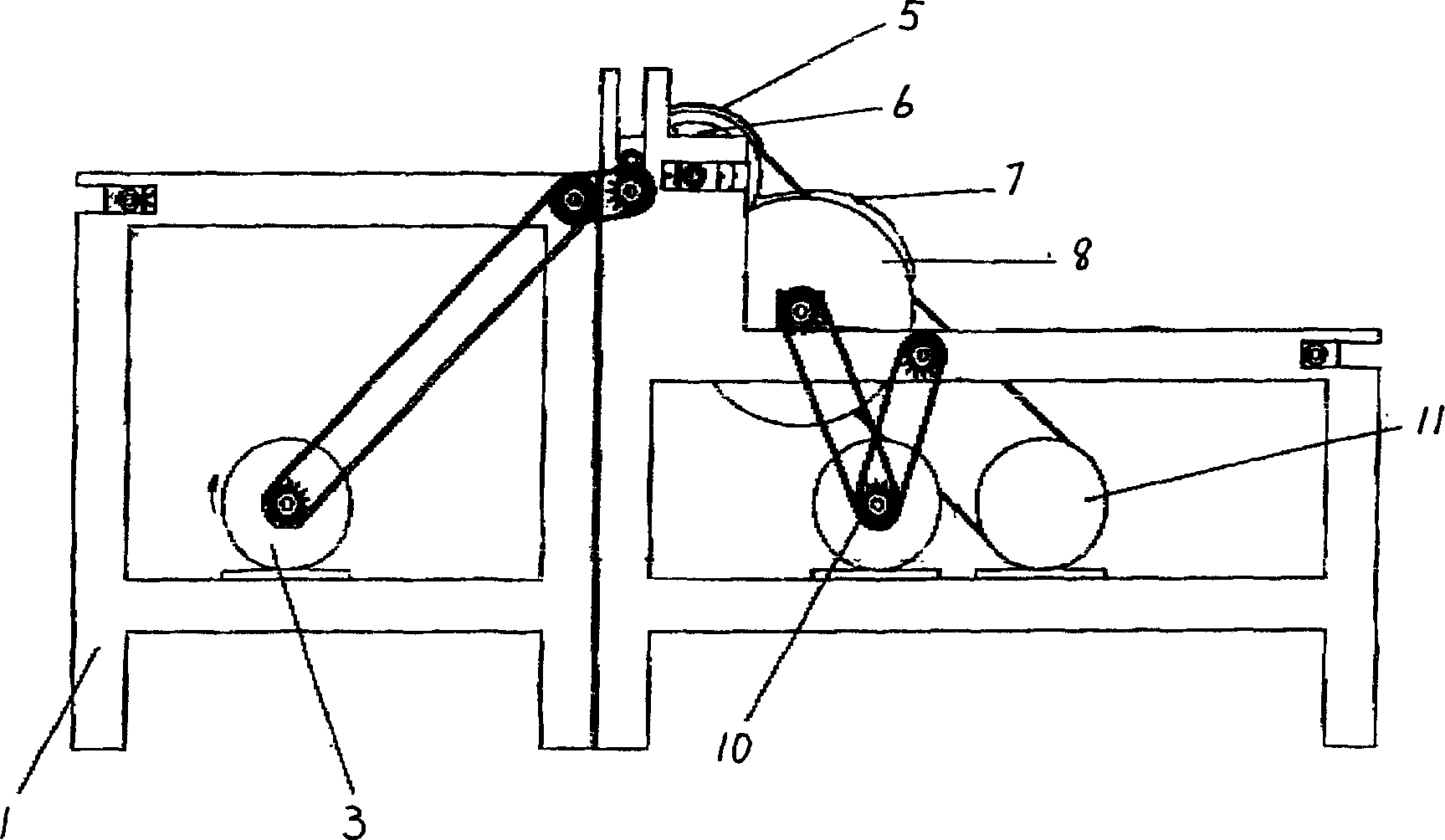

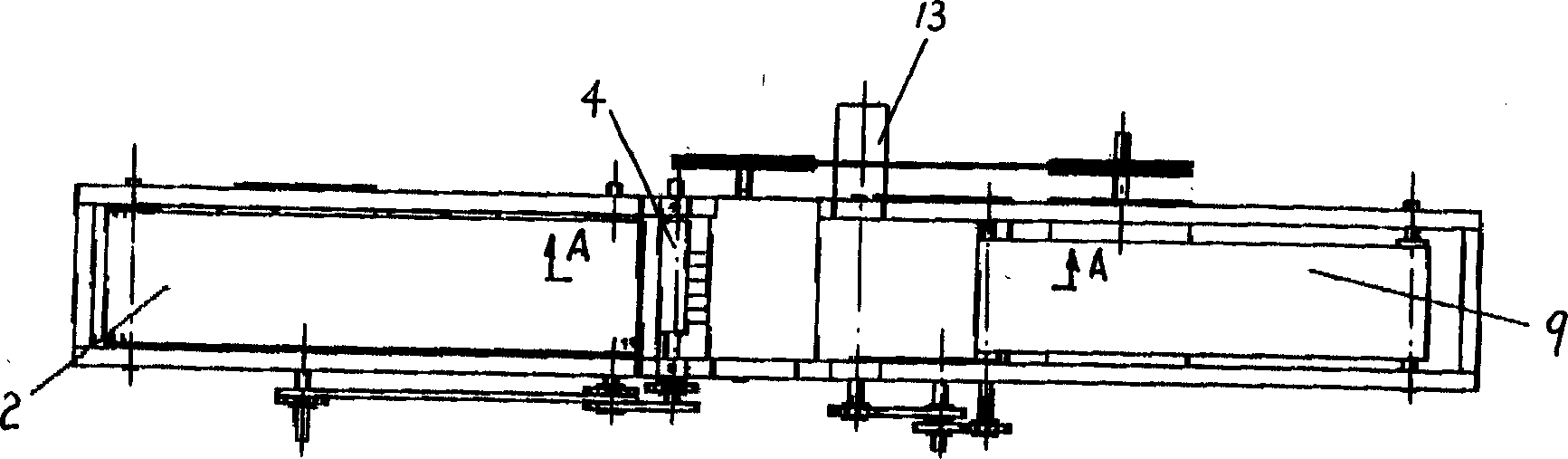

[0045] (5) extract fiber, extract the fiber of straw with extraction device;

[0046] (6) Filtration, the fibers and attached tissues are separated by a filtration device, and collected and stored separately.

Embodiment 2

[0047] Embodiment 2. extracts the method for wheat straw fiber, comprises the steps:

[0048] (1) stock preparation, raw material is selected from the stalk of wheat;

[0049] (2) remove miscellaneous, the stalk of wheat is removed dust sundry;

[0050] (3) Cooking, putting the stalk section into a cooking container with water;

[0051] (4) dehydration, dehydration of the cooked stalks, drying to a moisture content of 25% with a centrifuge;

[0052] (5) extract fiber, extract the fiber of straw with extraction device;

[0053] (6) Filtration, the fibers and attached tissues are separated by a filtration device, and collected and stored separately.

Embodiment 3

[0054] Embodiment 3. extract the method for corn stalk fiber, comprise the steps:

[0055] (1) preparing materials, raw materials are selected from corn stalks, which can be cut into sections;

[0056] (2) Remove impurities, remove dust and impurities from the corn stalks;

[0057] (3) Cooking, put the straw section into the cooking container with water and steam

[0058] (4) dehydration, dehydration of the cooked stalks, drying to a moisture content of 20% with a centrifuge;

[0059] (5) extract fiber, extract the fiber of straw with extraction device;

[0060] (6) Filtration, the fibers and attached tissues are separated by a filtration device, and collected and stored separately.

[0061]In the above examples, the cooking is generally carried out at 1-3 atmospheric pressure for 2-10 hours; then kept at 50°C to less than 100°C under normal pressure for 2-72 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com