Grinding stone, grinding member including the same, and manufacturing method of grinding member

A technology of grinding stones and grinding parts, which is applied in the direction of manufacturing tools, abrasives, grinding devices, etc., which can solve problems such as incompatibilities and achieve the best grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

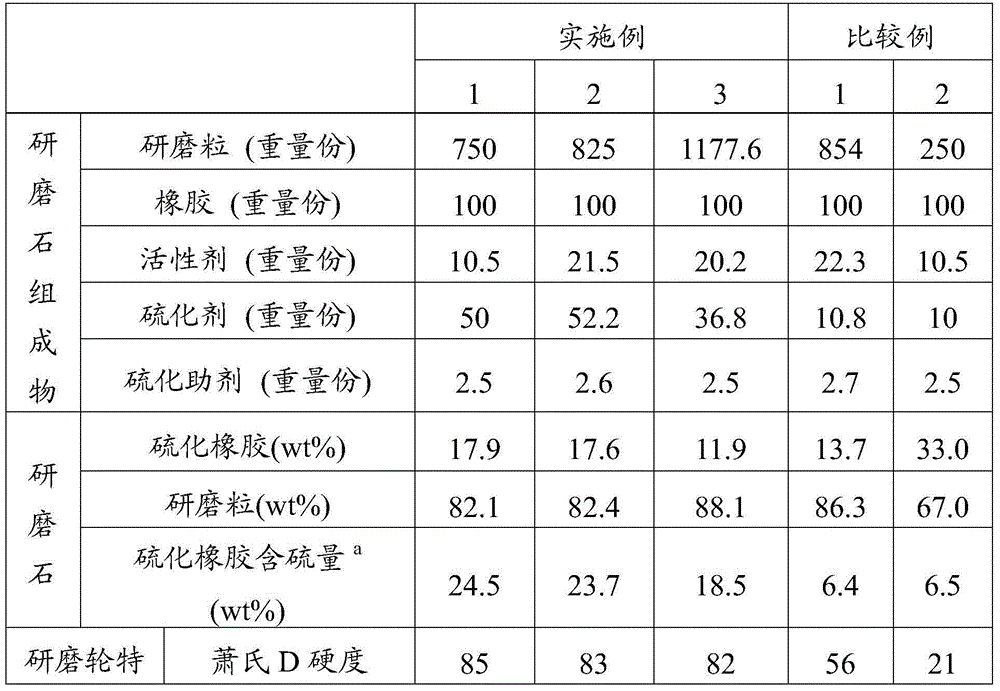

Embodiment 1

[0047] The first mixing step: 100g of styrene-butadiene rubber (hereinafter referred to as SBR) is placed on the rollers of 6-inch double rollers (manufacturer: Jin Naihe Industrial Co., Ltd., model: ML1-2-1) and rolled After making the SBR circle around the roller, slowly add 750g of ceria (manufacturer: China Baotou Steel, white powder, particle size D50=0.9μm), and active agent (8g of zinc oxide and 2.5g of stearin acid), and then mix SBR, cerium oxide and active agent uniformly in a triangular bag to obtain a mixture, then roll the mixture into a sheet and cool it for later use, the mixing temperature is 50°C to 100°C, and the mixing time is about 10 minutes to 20 minutes.

[0048] The second mixing step: this sheet is placed on the roller of 6 inch twin-roller (manufacturer: Jin Naihe Industrial Co., Ltd., model: ML1-2-1), adjusts the roller distance of twin-roller so that this sheet can be in Form a circle around the double rollers, slowly add 50g of insoluble sulfur (m...

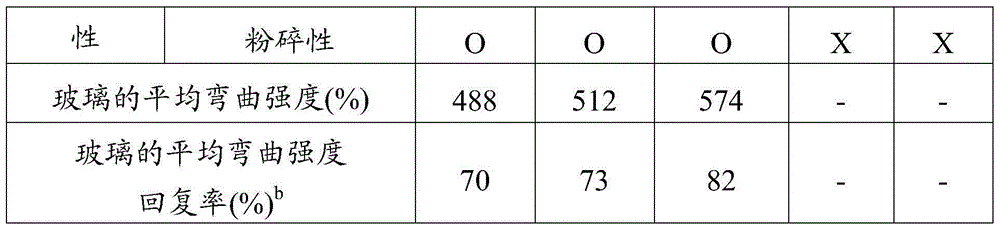

Embodiment 2 to 3、 comparative example 1 to 2

[0051] Examples 2 to 3 and Comparative Examples 1 to 2 were prepared in a manner similar to the preparation of the grinding wheel of Example 1, wherein the amounts of each component are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com