Gap forming type hardened soil treatment method

A soil and compaction technology, applied in the field of soil remediation, can solve the problems of limiting plant growth and yield, long cycle, passive soil improver, etc., and achieve the effect that it is not easy to accidentally fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

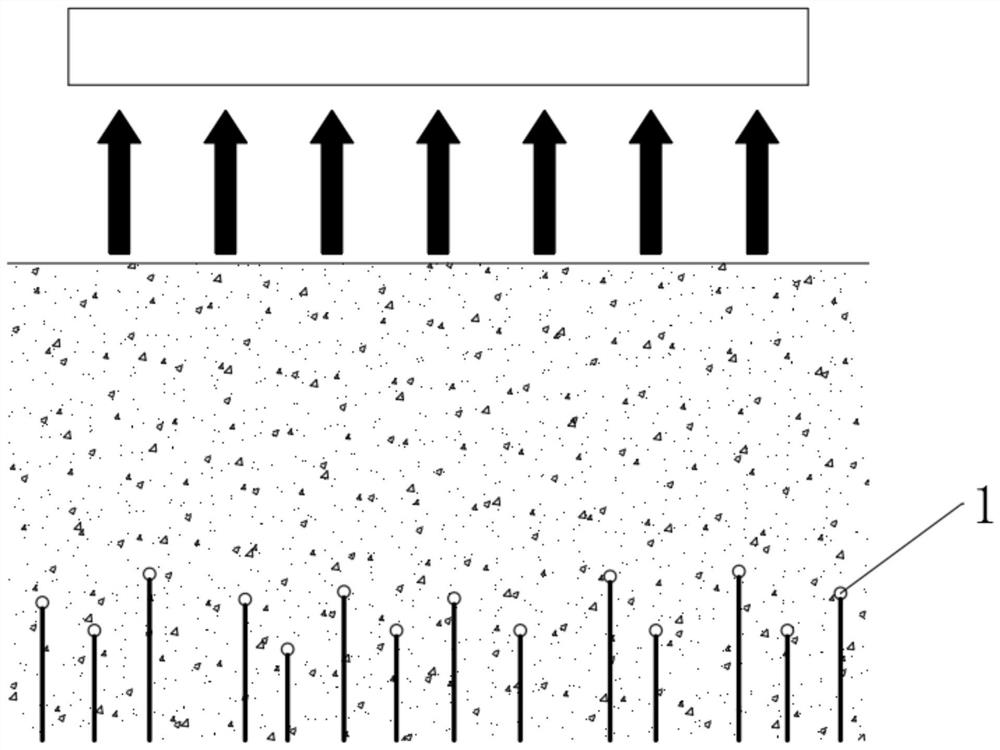

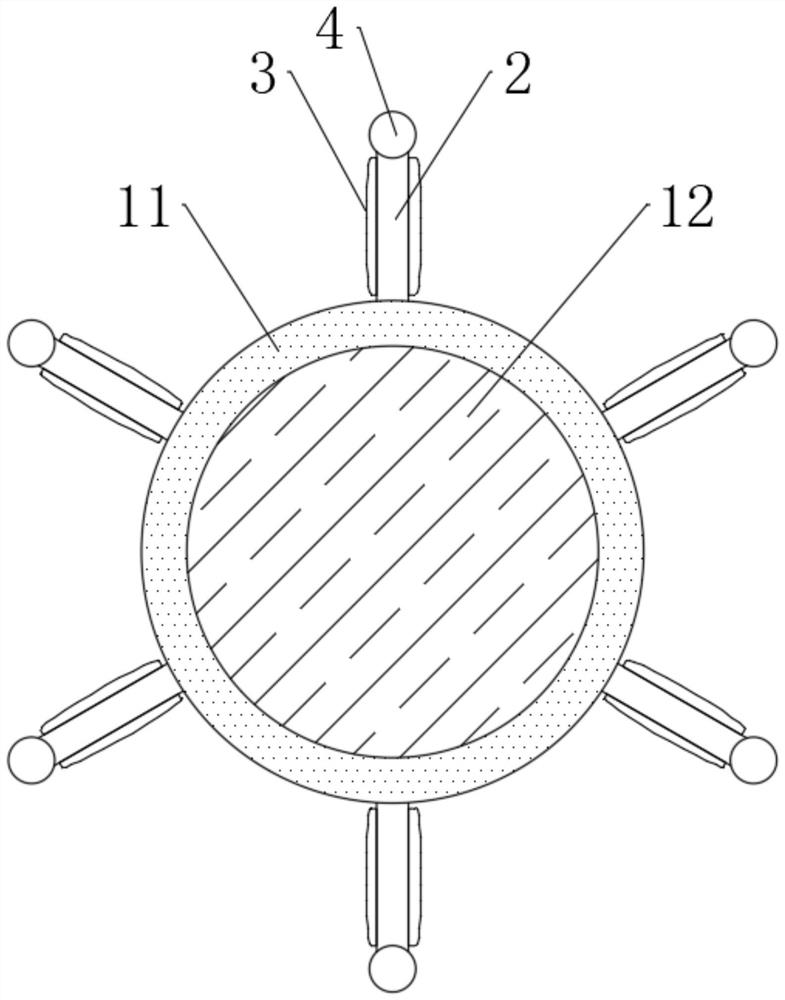

[0044] see figure 1 , a gap-making type compaction soil treatment method, comprising the following steps:

[0045] S1. Use a puncher to evenly punch holes in the compacted soil to be repaired, and then inject softening liquid into the holes, and wait until the softening liquid is absorbed by the soil;

[0046] S2. After the softening solution is absorbed by the soil until there is no obvious water accumulation in the hole, plow the soil, and evenly put the gap-making main ball 1 deep into the soil during the plowing process;

[0047] S3. After the plowing is completed, the soil is leveled, and then a magnetic field is immediately applied above the soil to force the main gap-making ball 1 to migrate from the depth of the soil to the surface by magnetic attraction, forming a macroscopic gap-making phenomenon;

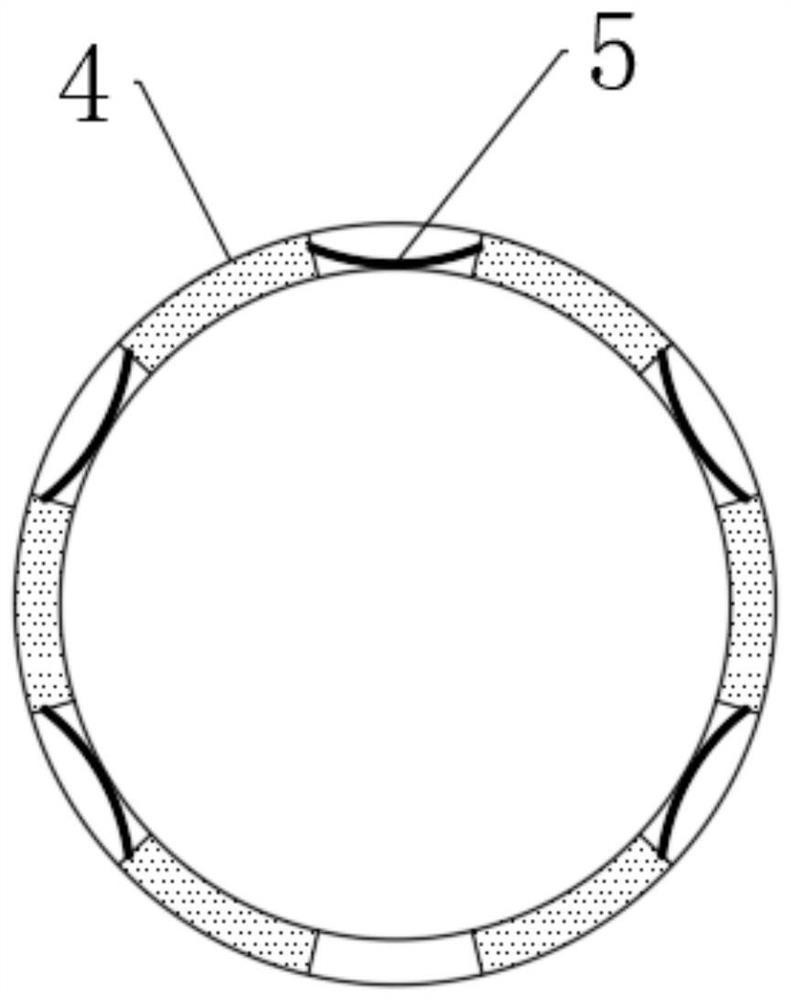

[0048] S4. During the process of migrating to the soil surface, the gap-making main ball 1 triggers a gas release action on the compacted soil encountered, forming a mic...

Embodiment 2

[0060] see figure 1 , a gap-making type compaction soil treatment method, comprising the following steps:

[0061] S1. Use a puncher to evenly punch holes in the compacted soil to be repaired, and then inject softening liquid into the holes, and wait until the softening liquid is absorbed by the soil;

[0062] S2. After the softening solution is absorbed by the soil until there is no obvious water accumulation in the hole, plow the soil, and evenly put the gap-making main ball 1 deep into the soil during the plowing process;

[0063] S3. After the plowing is completed, the soil is leveled, and then a magnetic field is immediately applied above the soil to force the main gap-making ball 1 to migrate from the depth of the soil to the surface by magnetic attraction, forming a macroscopic gap-making phenomenon;

[0064] S4. During the process of migrating to the soil surface, the gap-making main ball 1 triggers a gas release action on the compacted soil encountered, forming a mic...

Embodiment 3

[0071] see figure 1, a gap-making type compaction soil treatment method, comprising the following steps:

[0072] S1. Use a puncher to evenly punch holes in the compacted soil to be repaired, and then inject softening liquid into the holes, and wait until the softening liquid is absorbed by the soil;

[0073] S2. After the softening solution is absorbed by the soil until there is no obvious water accumulation in the hole, plow the soil, and evenly put the gap-making main ball 1 deep into the soil during the plowing process;

[0074] S3. After the plowing is completed, the soil is leveled, and then a magnetic field is immediately applied above the soil to force the main gap-making ball 1 to migrate from the depth of the soil to the surface by magnetic attraction, forming a macroscopic gap-making phenomenon;

[0075] S4. During the process of migrating to the soil surface, the gap-making main ball 1 triggers a gas release action on the compacted soil encountered, forming a micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com