Optical blue glass and preparation process thereof

A preparation process and technology of blue glass, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of easy accidental scratching, scrapping of top glass, etc. Good re-plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

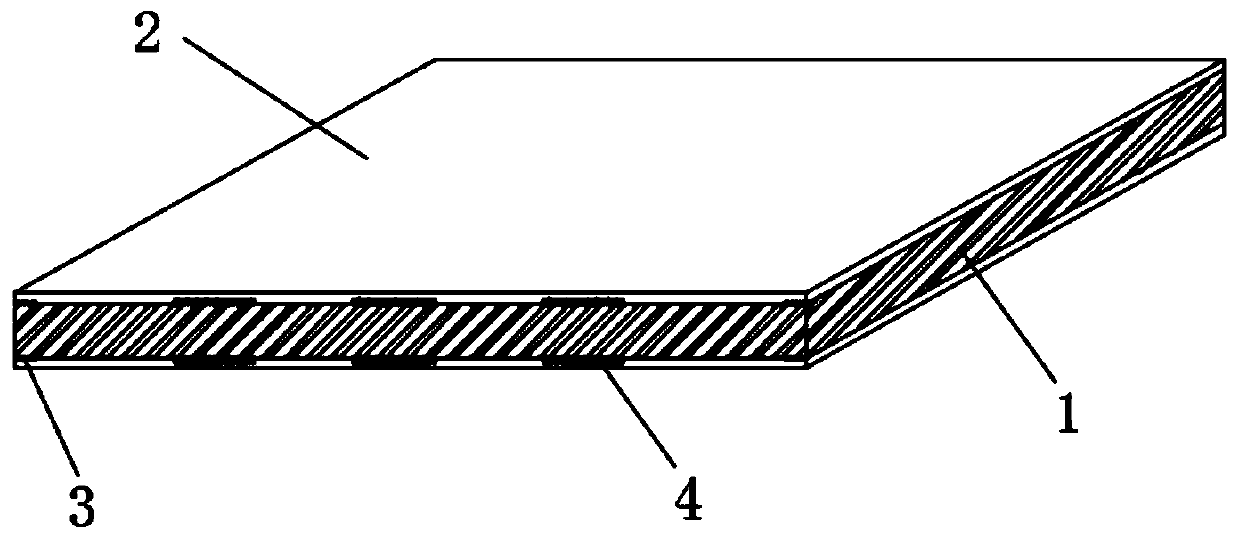

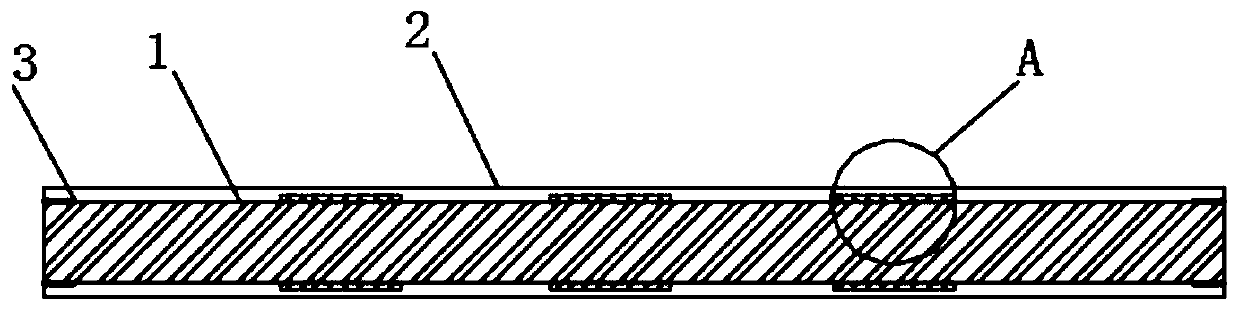

[0052] see Figure 6 , an optical blue glass, comprising a glass substrate 1, a self-absorbing film 2 pasted on the surface of the glass substrate 1, a plurality of self-adsorbing dot fields 4 are arranged on the pasting surface of the self-adsorbing film 2, and a plurality of self-adsorbing dot fields 4 Evenly arranged on the self-absorbing film 2, the self-adsorbing film 2 is pasted with gentle glue 3 around it, and the self-absorbing film 2 is fixedly connected with the glass substrate 1 through the gentle glue 3, and the surface of the glass substrate 1 is coated with a One-layer self-absorbing film 2, using the huge suction force of the liquid between the film and the glass substrate 1, combined with the stable bonding of mild glue, can protect the glass substrate 1. Compared with the traditional bare glass substrate, in this solution Even if the glass substrate 1 is cracked after annealing, it will hardly cause scratch damage to other intact glass substrates 1, so as to ...

Embodiment 2

[0065] see Figure 7 , an optical blue glass, comprising a glass substrate 1, a self-absorbing film 2 pasted on the surface of the glass substrate 1, and a layer of self-absorbing film 2 covering the surface of the glass substrate 1, which can protect the glass substrate 1. Compared with Compared with the traditional bare glass substrate, even if the glass substrate 1 in this solution bursts after annealing, it will hardly cause scratch damage to other intact glass substrates 1, ensuring the integrity of the glass substrate 1 placed or transported together. Also, see Figure 7 , even if the glass substrate accidentally bursts, its fragments will basically not splash randomly under the "adhesion" effect of the self-absorbing film 2, which further provides a guarantee for the safety of other glass substrates 1.

[0066] The self-absorbing film 2 is a transparent plastic film, which is convenient for relevant staff to directly observe the type of glass substrate 1 inside, and th...

Embodiment 3

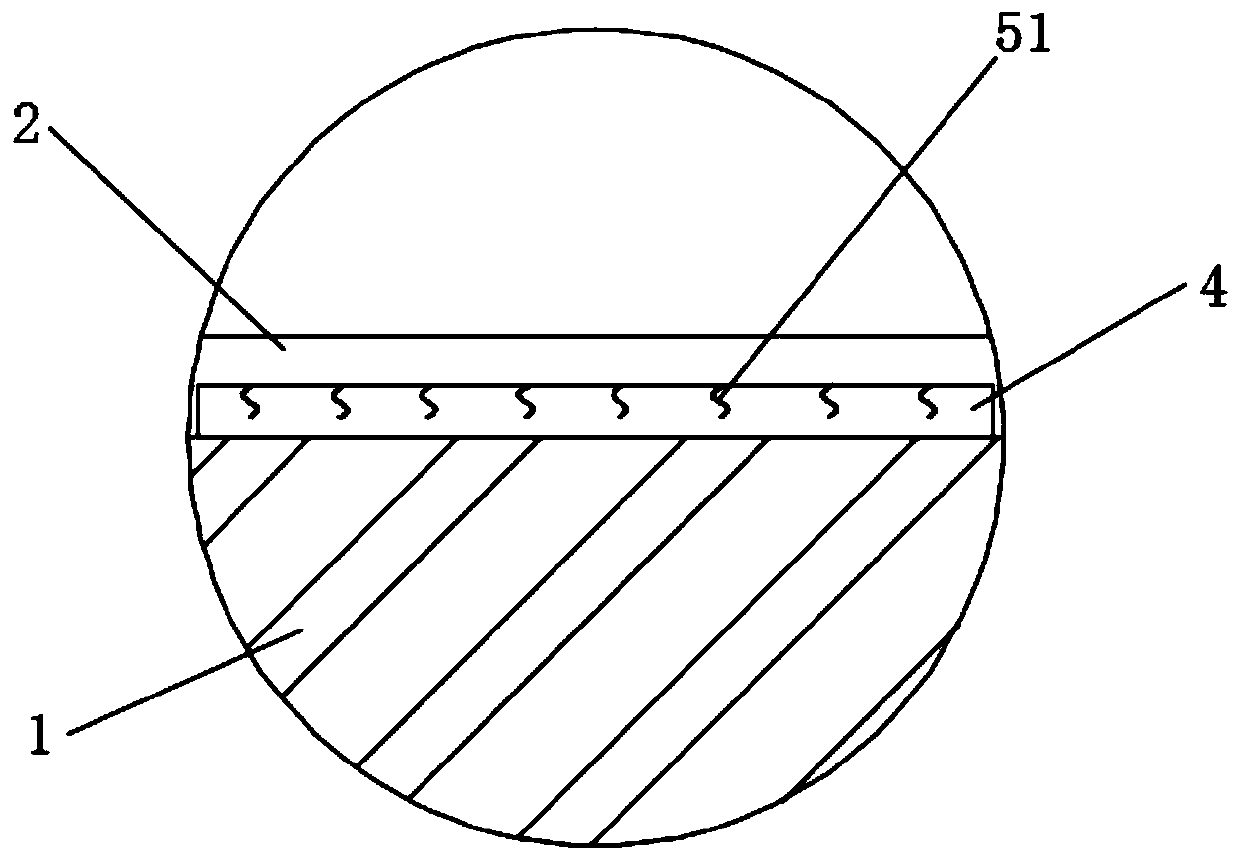

[0077] see figure 1 , Figure 4 and Figure 5, an optical blue glass, comprising a glass substrate 1, a self-absorbing film 2 pasted on the surface of the glass substrate 1, a plurality of self-adsorbing dot fields 4 are arranged on the pasting surface of the self-adsorbing film 2, and a plurality of self-adsorbing dot fields 4 Evenly arranged on the self-absorbing film 2, the self-positioning cotton block 52 is arranged inside the self-adsorbing point area 4, and the self-positioning cotton block 52 is soaked with natural suction liquid, and the self-adsorbing film 2 is pasted with gentle glue 3 around it , and the self-absorbing film 2 is fixedly connected to the glass substrate 1 through gentle dispensing 3, and a layer of self-absorbing film 2 is coated on the surface of the glass substrate 1, and the huge suction force of the liquid between the film and the glass substrate 1 is used to coordinate with the gentle The stable bonding of the glue can protect the glass subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com