Anti-blocking device for double-in and double-out ball type coal pulverizer separator

A double-inlet, double-outlet, separator technology, applied in grain processing, etc., can solve the problems of not fully adapting to the needs of on-site transformation, high cost of transformation schemes, heavy maintenance workload, etc., to ensure the fineness and uniformity of coal powder, Effect of reducing quantity and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

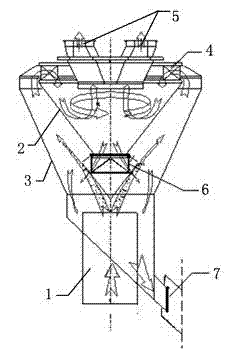

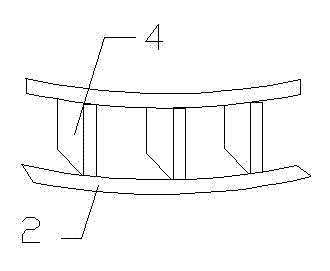

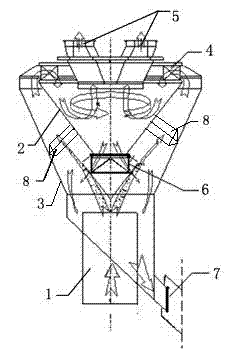

[0017] Such as image 3 with Figure 4 As shown, the present invention includes an outer cone 3, an inner cone 2 and a separator inlet radial baffle 4 arranged on the inner cone 2, and the end side of the separator inlet radial baffle 4 is connected to the inner cone 2 The outer edge of the upper end surface is flush with each other, a plurality of axial separation baffles 8 are evenly arranged between the outer cone 3 and the wall of the inner cone 2, and no more than 30 separators are evenly arranged on the inner cone 2 along the circumference. The mouth is radial to the baffle 4, and the length of the radial baffle 4 at the inlet of the separator is not less than 260mm. In this embodiment, 20 separator inlet radial baffles 4 are evenly arranged on the inner cone along the circumference, and the length of the separator inlet radial baffles 4 is 380mm.

[0018] When the present invention is in use, the sundries contained in the rising pulverized coal airflow will be attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com