Milltailing collecting and transportation device and core shooter milltailing recovery method

A transport device and core shooter technology, which is applied to parts of molding machines, machinery for cleaning/processing mold materials, and casting molding equipment, etc. and transportation, to achieve smooth transportation, and to improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

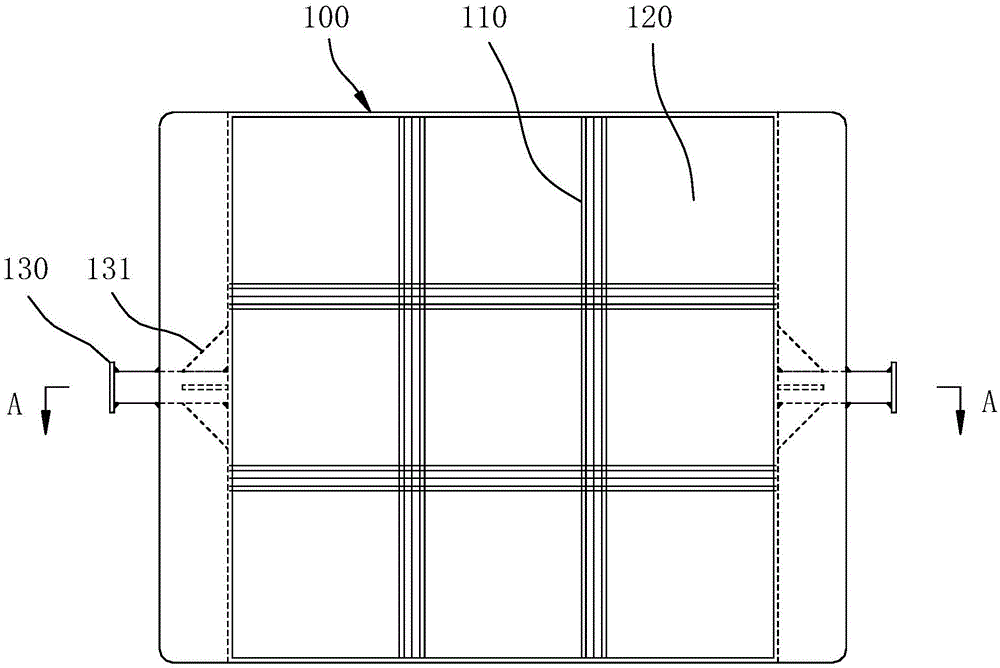

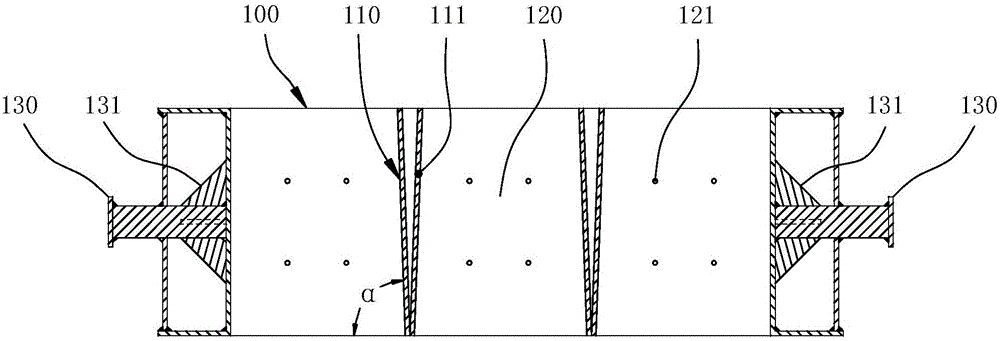

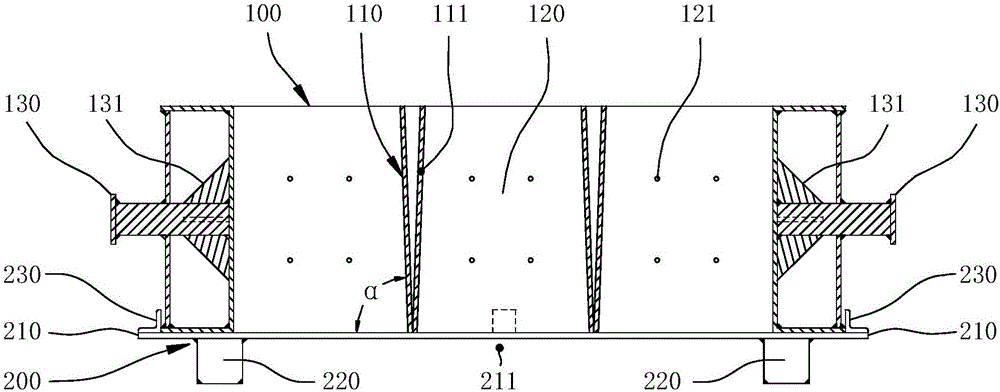

[0033] to combine figure 1 with figure 2 As shown, the tailings collection and transportation device includes a tailings collection box 100, the top and bottom of the tailings collection box 100 are open, and the tailings collection box 100 is provided with a partition 110 with a V-shaped cross section. There is at least one partition 110 , and the partition 110 divides the inner cavity of the tailings collection box 100 into at least two sand storage spaces 120 . Wherein, the partition 110 is usually welded and installed in the tailings collection box 100 , and the partition 110 can also be detachably arranged in the tailings collection box 100 . The set partition 110, on the one hand, can divide the space in the tailings collection box 100, so that the size of the loaded tailings after solidification always meets the specified size range of the sand regeneration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com