Machine tool

A machine tool and bed technology, applied in the field of processing machinery, can solve problems such as the influence of the processing drill bit, the injury of the operator, and the easy splashing of chips, so as to improve the processing speed and processing quality, prolong the service life, and facilitate cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

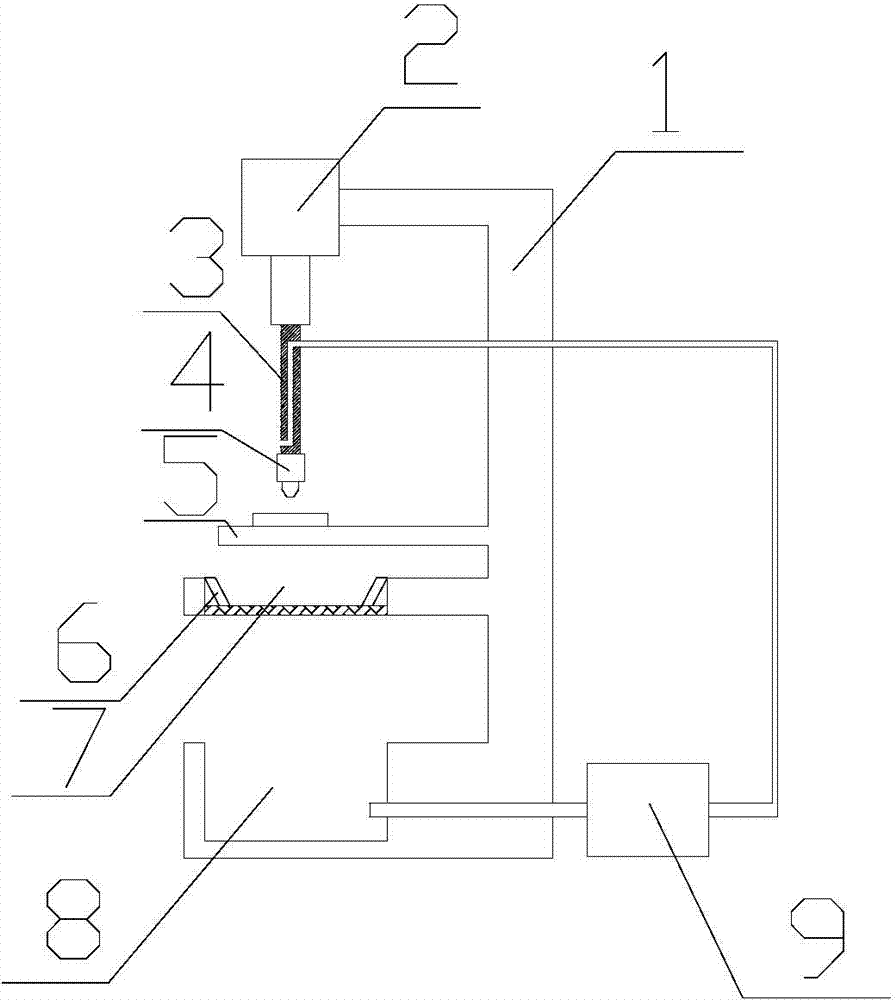

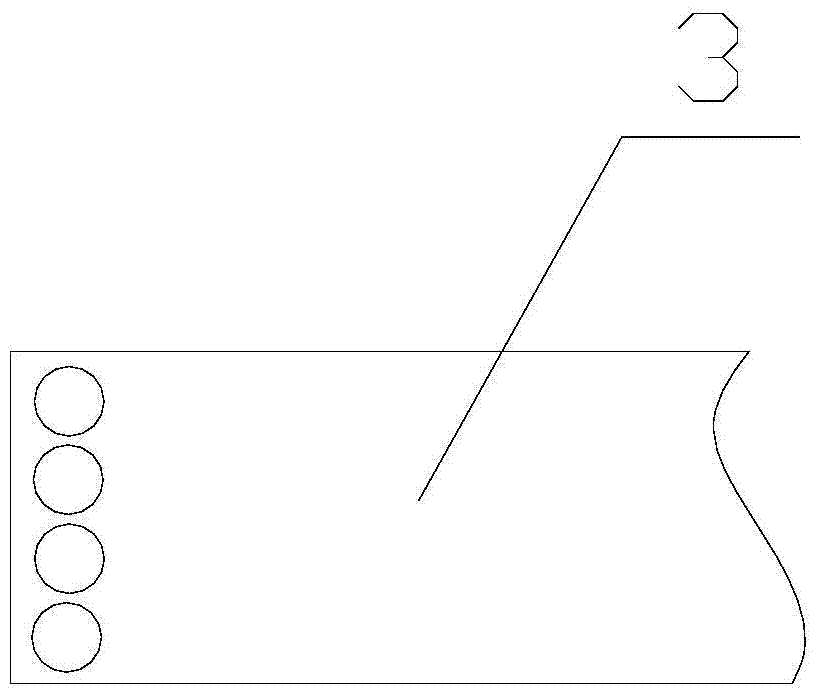

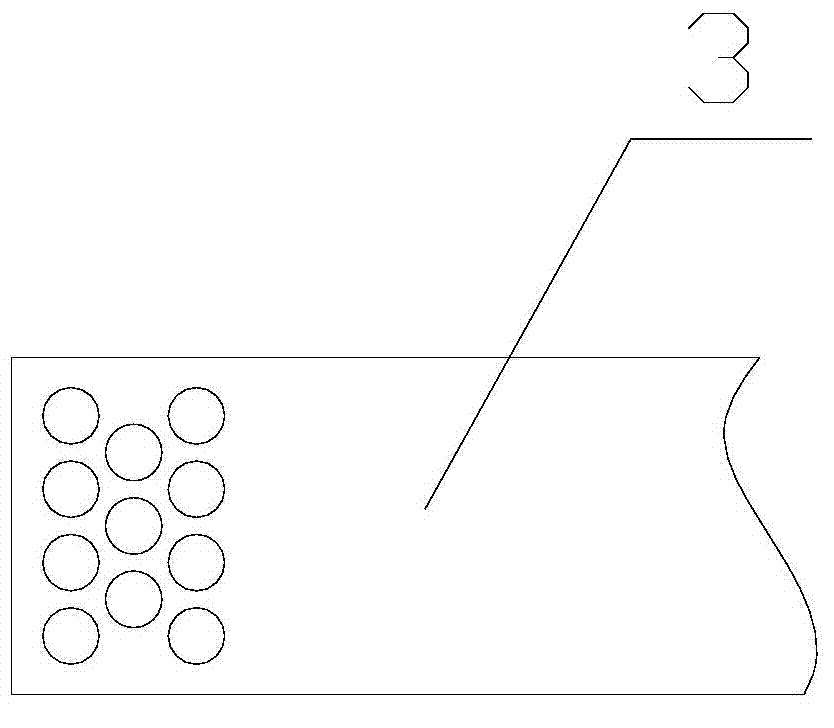

[0017] Such as Figure 1-Figure 3 shown figure 1 A structural schematic diagram of a machine tool proposed by the present invention; figure 2 It is a schematic diagram of the partial structure of the drill pipe of an embodiment of a machine tool proposed by the present invention; image 3 It is a schematic diagram of the partial structure of the drill pipe of another embodiment of a machine tool proposed by the present invention.

[0018] refer to figure 1 , a kind of machine tool that the present invention proposes, comprises: lathe bed 1, driving device 2, clamp mechanism 5, processing mechanism, wherein: driving device 2, clamp mechanism 5, processing mechanism are installed on the bed 1, and processing mechanism comprises drill rod 3. One end of the drill pipe 3 is provided with a first connection structure 4 that can be installed with a drill bit. The output shaft of the drive device 2 is connected to the end of the drill pipe 3 away from the first connection structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com