PVC composite plate and preparation method thereof

A composite board and PVC resin technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as wear resistance, compressive strength, high formaldehyde content, and inconvenient handling , to achieve good compressive strength, high foaming strength and lower density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

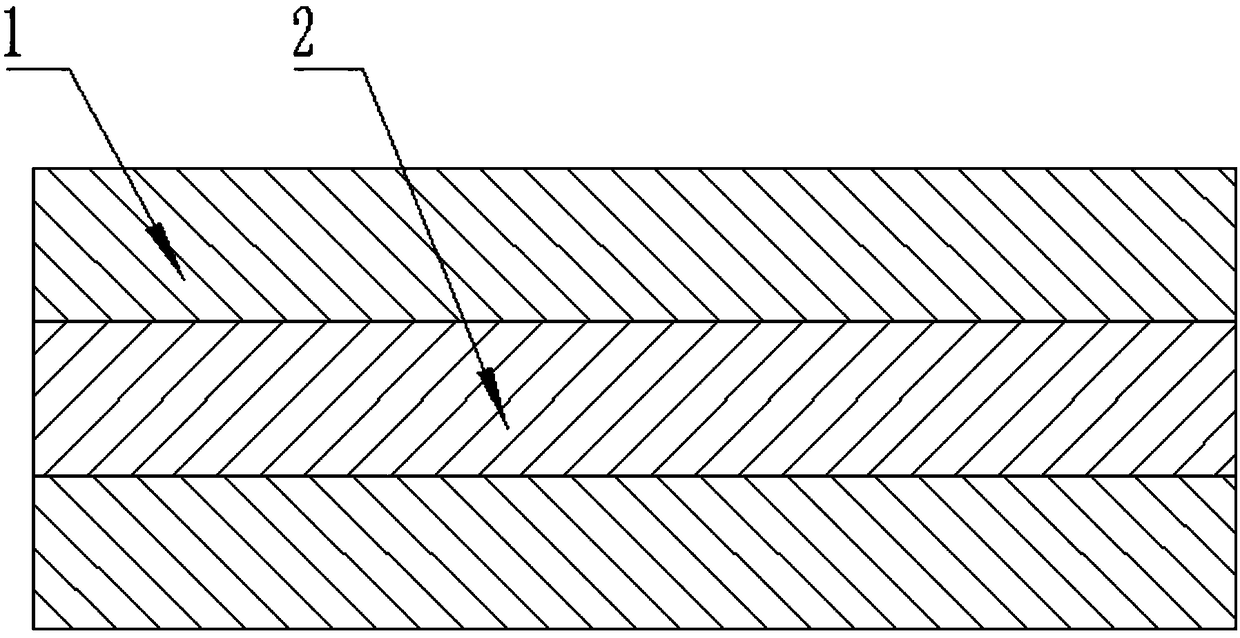

[0042] A PVC composite board, the PVC composite board is a composite layer structure, such as figure 1 As shown, it includes the outer layer 1 of the board and the inner layer 2 of the board arranged between the outer layers. The outer layer of the board includes the following components by weight: 47 parts of PVC resin, 32 parts of nano light calcium carbonate, 5 parts Calcium zinc stabilizer, 0.18 part of internal lubricant 316A, 0.8 part of internal lubricant G-60, 1 part of PVC foam regulator H-100A, 0.18 part of ACR-401, 1 part of titanium dioxide.

[0043] In the outer layer of the board, the PVC resin includes 15 parts of PVC resin SG-5 and 32 parts of PVC resin SG-8.

[0044] In parts by weight, the inner layer of the board includes: 40 parts of PVC resin, 35 parts of nano light calcium carbonate, 2.5 parts of calcium zinc stabilizer, 0.7 part of internal lubricant 316A, 0.6 part of internal lubricant G-60, 4 1 part of PVC foam regulator H-100A, 0.8 part of white foa...

Embodiment 2

[0055] A PVC composite board, the PVC composite board is a composite layer structure, such as figure 1 As shown, including the board outer layer 1 and the board inner layer 2 arranged between the outer layers, the board outer layer includes the following components by weight: 58 parts of PVC resin, 38 parts of nano light calcium carbonate, 7 parts Calcium zinc stabilizer, 0.22 parts of internal lubricant 316A, 1.2 parts of internal lubricant G-60, 1.5 parts of PVC foam regulator H-100A, 0.22 parts of ACR-401, 1.5 parts of titanium dioxide.

[0056] In the outer layer of the board, the PVC resin includes 20 parts of PVC resin SG-5 and 38 parts of PVC resin SG-8.

[0057] In parts by weight, the inner layer of the board includes: 60 parts of PVC resin, 42 parts of nano light calcium carbonate, 3.5 parts of calcium zinc stabilizer, 0.9 part of internal lubricant 316A, 0.8 part of internal lubricant G-60, 6 1 part of PVC foam regulator H-100A, 1 part of white foaming agent, 0.7 ...

Embodiment 3

[0068] A PVC composite board, the PVC composite board is a composite layer structure, such as figure 1 As shown, it includes the outer layer 1 of the board and the inner layer 2 of the board arranged between the outer layers. The outer layer of the board includes the following components by weight: 53 parts of PVC resin, 35 parts of nano light calcium carbonate, 6 parts Calcium zinc stabilizer, 0.2 parts of internal lubricant 316A, 1 part of internal lubricant G-60, 1.2 parts of PVC foam regulator H-100A, 0.2 parts of ACR-401, 1.2 parts of titanium dioxide.

[0069] In the outer layer of the board, the PVC resin includes 18 parts of PVC resin SG-5 and 35 parts of PVC resin SG-8.

[0070] In parts by weight, the inner layer of the board includes: 50 parts of PVC resin, 40 parts of nano light calcium carbonate, 3 parts of calcium zinc stabilizer, 0.8 part of internal lubricant 316A, 0.7 part of internal lubricant G-60, 5 parts 1 part of PVC foam regulator H-100A, 0.9 part of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com