Rotary compressor and its manufacturing method

A technology of a rotary compressor and a manufacturing method, which is applied in the directions of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problems of high production cost of sliding vanes and pistons, poor impact resistance, and high operating pressure, and achieves high resistance to Strong impact ability, good wear resistance, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

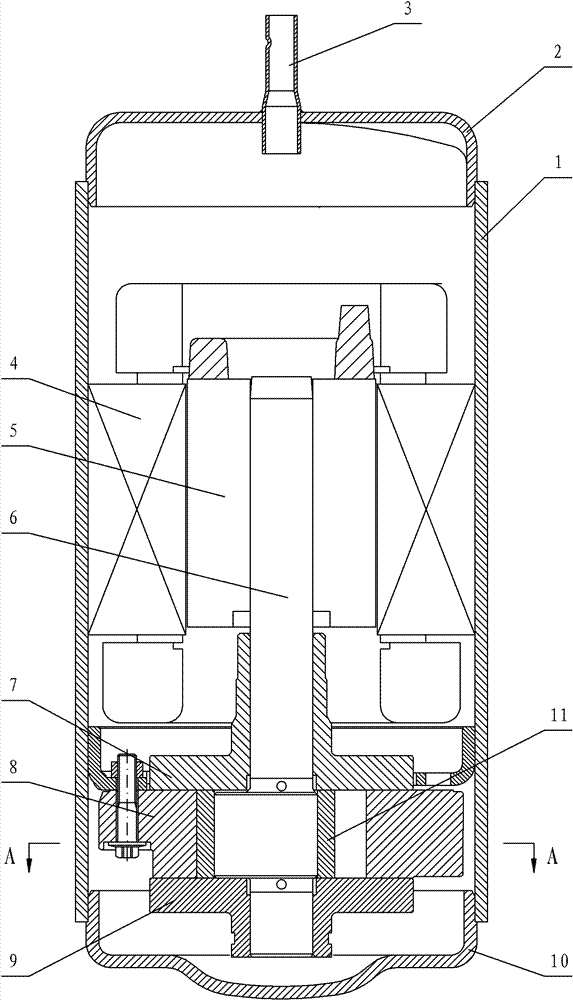

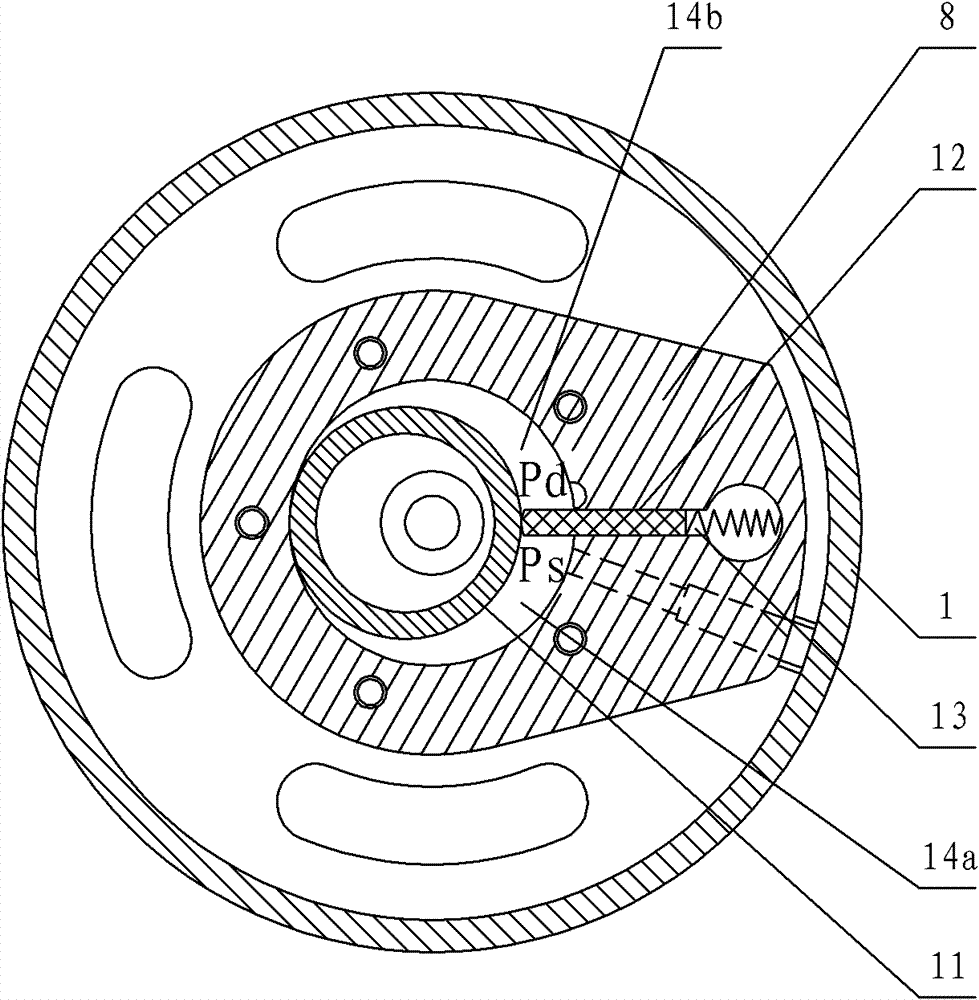

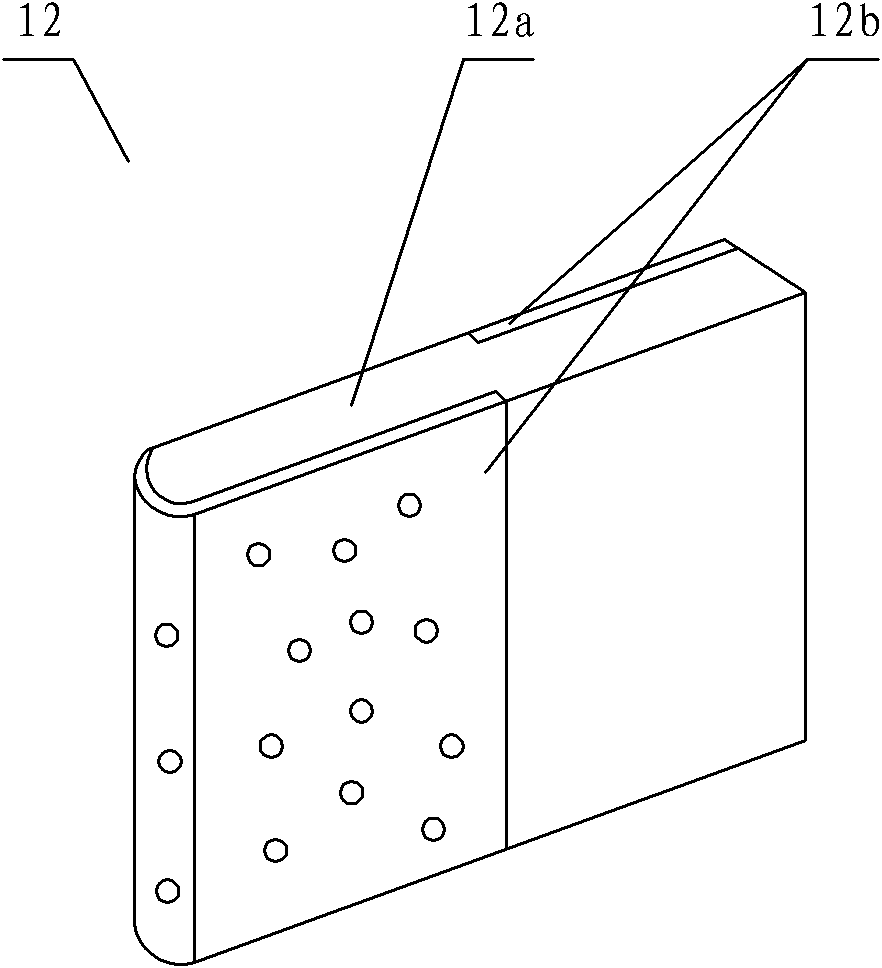

[0028] see image 3 , the rotary compressor includes a motor and a compression mechanism arranged in the housing, the compression mechanism includes a cylinder 8 with a compression cavity, a piston 11 that rotates eccentrically in the compression cavity, and a slide plate 12 is also arranged on the cylinder 8 Slide groove 13, one end of slide 12 abuts against the outer circumference of piston 11, slide 12 includes slide metal base 12a, and slide ceramic composite layer 12b arranged on slide metal base 12a; slide ceramic composite layer 12b is arranged on one side, both sides or the tip of the slider metal base 12a. The metal matrix 12a of the sliding vane is a cast iron matrix or a steel matrix. The slider ceramic composite layer 12b includes a porous slider ceramic layer and metal embedded in the slider ceramic layer. The sliding ceramic layer is an aluminum oxide layer, a silicon oxide layer or a zirconium oxide layer.

[0029] When making, first prepare a porous sliding ...

no. 2 example

[0031] see Figure 4-Figure 5 , The piston 11 in this embodiment includes a piston metal base 11a, and a piston ceramic composite layer 11b disposed on the piston metal base 11a; the piston ceramic composite layer 11b is disposed on the inner or outer circumference of the piston metal base 11a. The metal matrix 11a of the piston is a cast iron matrix or a steel matrix. The piston ceramic composite layer 11b includes a porous piston ceramic layer 11c and metal embedded in the piston ceramic layer 11c. The piston ceramic layer 11c is an alumina layer, a silicon oxide layer, a zirconia layer, a silicon carbide layer or a zirconia layer.

[0032] During production, at first prepare the porous piston ceramic layer 11c as required, and the wall degree of the piston ceramic layer 11c is 0.5-10mm; then place the piston ceramic layer 11c on the core 15 in the mold 18, and then cast the liquid metal 17 into the In the casting mold 18, a part of the liquid metal 17 enters the piston ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com