Crane

A crane and motor technology, applied in cranes and other directions, can solve the problems of inability to meet work requirements and low usability, and achieve the effect of convenient height adjustment and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

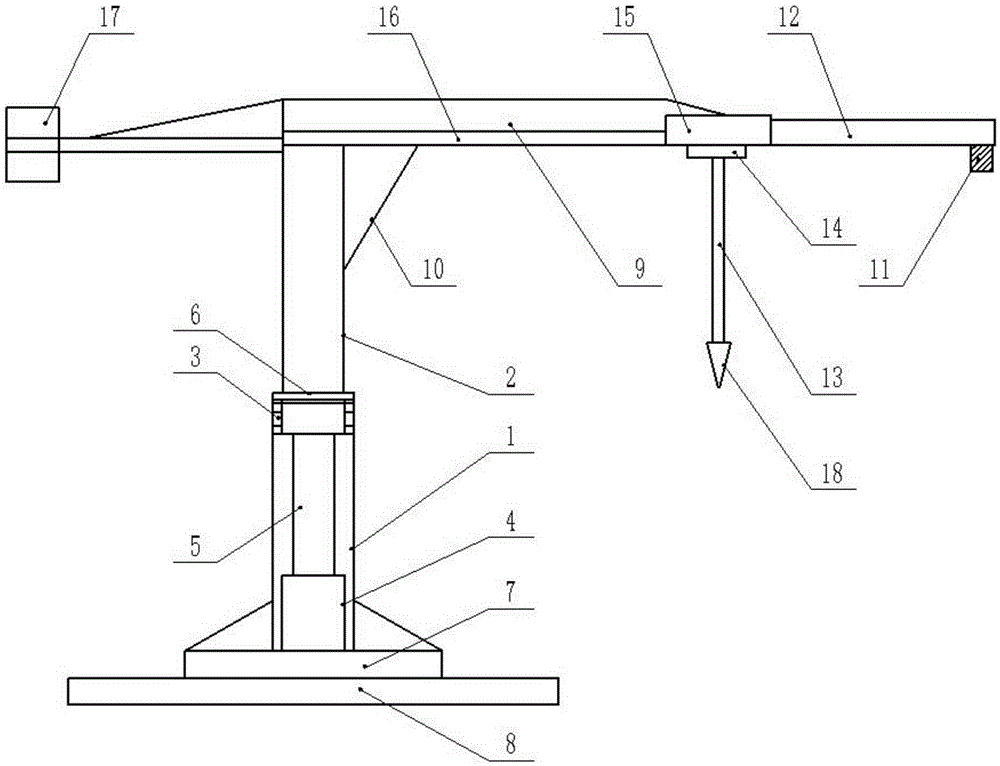

[0014] see figure 1 , a crane, comprising an outer cylinder 1, an inner cylinder 2 and a cantilever 9; the inner cylinder 2 is sleeved in the outer cylinder 1, a cantilever 9 is installed on the top of the inner cylinder 2, and a rubber gasket 3 is set on the inner cylinder 2, The rubber gasket 3 is located between the inner cylinder 2 and the outer cylinder 1; when in use, the rubber gasket 3 acts as a seal to prevent dust and the like from falling into the gap, and can also prevent the inner cylinder 2 and the outer cylinder 1 from rubbing against each other to cause abrasion. Function: a hydraulic drive system 4 is installed at the bottom of the outer cylinder 1, and a shock absorber 7 is provided under the hydraulic drive system 4, and the bottom end of the inner cylinder 2 is always socketed inside the outer cylinder 1, and the bottom end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com