Amorphous inner-coated pipe and method for producing same

A manufacturing method, amorphous technology, applied in coating, manufacturing tools, metal material coating process, etc., can solve the problems of inconvenient coating, difficult coating operation, difficulty in applying pipes with small inner diameters, etc., and achieve improvement Effect of Coating Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 8

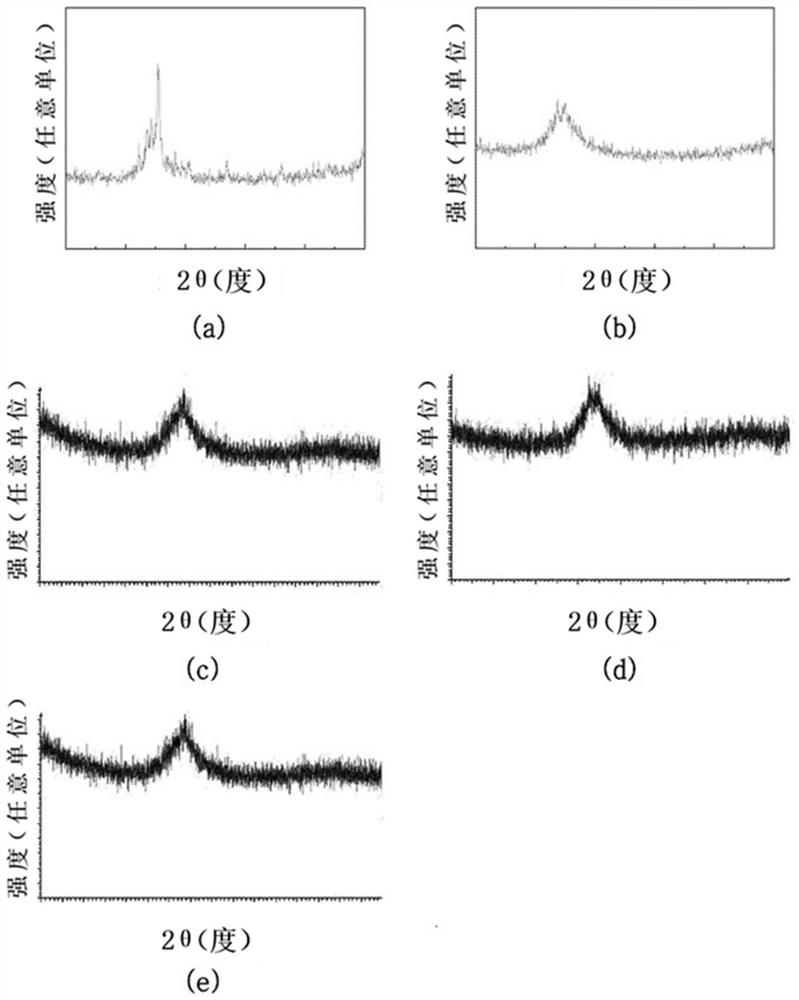

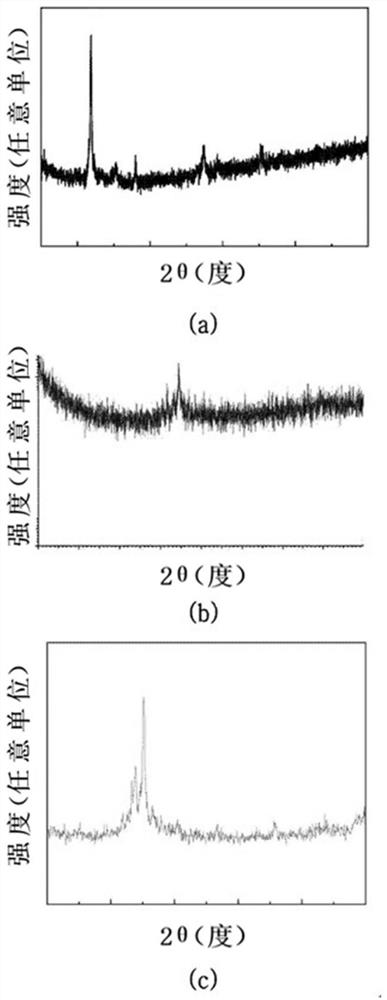

[0089] [Example 1 to Example 8: Production of Iron-based Amorphous Alloy Powder]

[0090] After being supplied to the inside of the atomizer under the nitrogen atmosphere according to the composition shown in the following table 1 and the composition of the weight ratio (weight ratio), atomize in a molten state and cool according to the cooling rate recorded in the following table 1, thereby The iron-based amorphous alloy powders of Examples 1 to 8 were produced.

[0091] 【Table 1】

[0092]

[0093] *D50 (unit: μ)

[0094] As shown in the above Table 1, the embodiments of the present invention include the first component to the fourth component in a specific content range, and in 10 1 to 10 4 Degrees per second cooling rate to produce alloy powders with an average powder diameter in the range of 5μ to 50μ.

Embodiment 9 to Embodiment 16

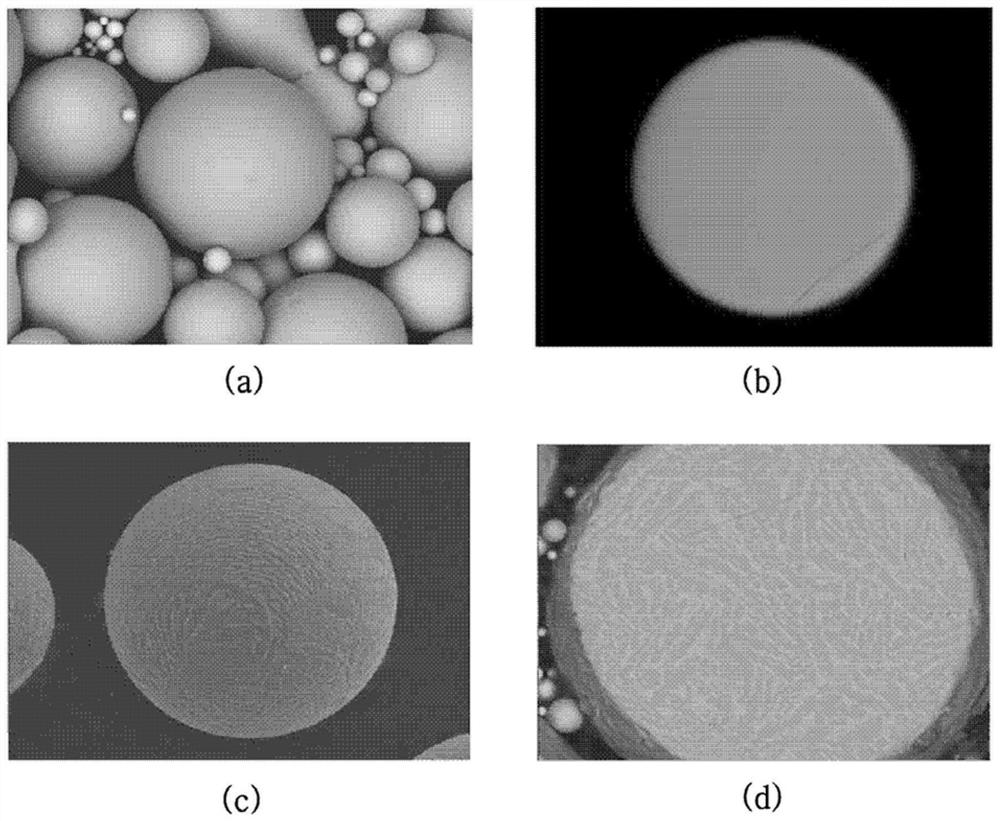

[0095] [Example 9 to Example 16: Manufacture of a pipe material formed with an iron-based amorphous coating]

[0096] On one surface of a sheet made of carbon steel, spray-coat the iron-based amorphous alloy powders of Examples 1 to 8 with a thickness of 0.1 mm, respectively, and then coat the above-mentioned coated sheet with A 3-inch-diameter pipe with an amorphous inner surface coating was produced by coiling it into the shape of a pipe with the cloth surface constituting the inner surface, and finally joining the seams to keep the sheet in the shape of the pipe.

[0097] In addition, a Sulzer Metco Diamond Jet unit was used to perform the spraying at 45% Oxygen flow, 48% Propane flow, 52% Air flow, Feeder rate 336%, Nitrogen flow (Nitrogen flow) 15 ~ 20RPM and stand-off distance (Stand-off) 12 inches under the conditions of implementation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com