A kind of high-performance rubber for generator shock absorber and its preparation process

A technology for shock-absorbing pads and generators, which is applied in the field of high-performance rubber for shock-absorbing pads of generators and its preparation process, can solve the problem of low breaking strength and elongation at break, high hardness of shockproof rubber compositions, and enhanced comprehensive performance. limited and other problems, to achieve the effect of increasing Shore hardness, improving anti-aging properties, and good and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

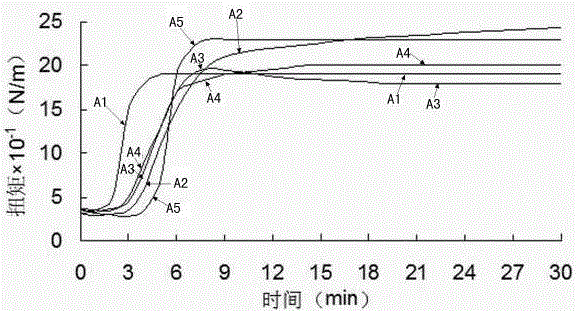

Image

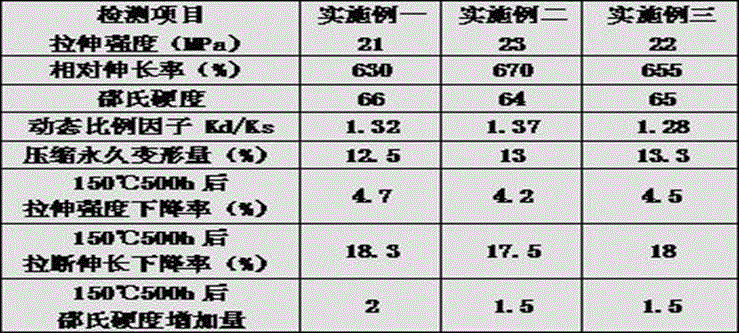

Examples

Embodiment 1

[0029] A preparation process of high-performance rubber for generator damping pads includes the following steps:

[0030] ①Pre-mixing: Use an appropriate amount of xylene solution as a solvent. After heating to 80°C, add 0.5 part of m-phenylenediamine. After it is completely dissolved, add 0.5 part of accelerator BMI. After stirring for 5 minutes at 90°C, the xylene Evaporate it, and then dry it in an oven at 60°C for 5 minutes, then pulverize it into powder with a grinder for use;

[0031] ②Mixing: To 100 parts of natural rubber, add 0.1 part of peptizing agent DBD, squeeze it on a double-roller mill for 5 times, then add 4 parts of 100 mesh zinc oxide and 0.9 parts of hard Fatty acid, 0.2 parts of anti-scorching agent CTP, and 28 parts of spray carbon black are added for mixing. The mixing temperature of the front roll is 55℃, and the mixing temperature of the back roll is 50℃. After the mixing is uniform, the sheet is discharged;

[0032] ③Vulcanization: Put the kneaded film into...

Embodiment 2

[0034] Based on the process of Example 1, the following formula and process parameters were changed: in the pre-mixing step, 0.55 parts of meta-phenylenediamine and 0.55 parts of accelerator BMI were used, and stirred at 90°C for 6 minutes; in the mixing step, 0.15 parts were used Peptizer DBD, 4.5 parts of 100 mesh zinc oxide, 1 part of stearic acid, 0.25 part of scorch inhibitor CTP, and 30 parts of spray carbon black for mixing. The mixing temperature of the front roller is 57℃, and the mixing temperature of the rear roller is 57℃. The temperature is 52°C; in the vulcanization step, 3 parts of the vulcanizing agent DCP are added and vulcanized at 170°C under normal pressure for 27 minutes to obtain the desired product.

Embodiment 3

[0036] On the basis of the process of Example 1, the following formula and process parameters were changed: in the pre-mixing step, 0.6 parts of meta-phenylenediamine and 0.6 parts of accelerator BMI were used, and stirred at 90°C for 7 minutes; in the mixing step, 0.2 part was used Peptizer DBD, 5 parts of 100 mesh zinc oxide, 1.1 parts of stearic acid, 0.3 parts of anti-scorching agent CTP, and 32 parts of spray carbon black for mixing. The mixing temperature of the front roller is 60℃, and the mixing temperature of the rear roller is 60℃. The temperature is 55°C; in the vulcanization step, 3.5 parts of vulcanizing agent DCP are added, and vulcanized at 175°C under normal pressure for 30 minutes to obtain the desired product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com