High-strength high-elongation flame retardant rubber insulated cable material and preparation process thereof

A flame-retardant rubber and insulated cable technology, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of easy-to-break elongation, low elongation at break, narrow process range, etc. The effect of improving performance and overcoming the difficulty of placing glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

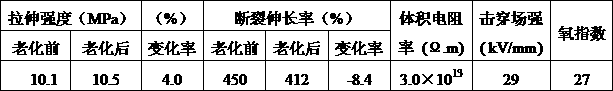

Embodiment 1

[0052] Example 1. A high-strength and high-elongation flame-retardant rubber insulating cable material. The composition of the material is: chlorinated polyethylene (CPE) 12 kg, ethylene-octene copolymer elastomer (POE) 19 kg, 800 #5 kg of paraffin-based rubber oil, 0.8 kg of activated magnesium oxide, 1.5 kg of zinc oxide, 5 kg of superfine talcum powder, 0.5 kg of environmental stabilizer, 1.5 kg of microcrystalline wax, 0.8 kg of titanium dioxide, and 3 kg of fumed white carbon black , 13 kg of calcined clay, 19 kg of aluminum hydroxide, 0.6 kg of 4,4′ bis(α,α dimethylbenzyl) diphenylamine, 1.5 kg of dicumyl peroxide, and 1.2 kg of triallyl cyanurate Kilogram.

[0053] The mass fraction of the octene monomer in the above-mentioned ethylene-octene copolymer elastomer is 20%-30%.

[0054] Preparation method: first mix chlorinated polyethylene (CPE) and ethylene-octene copolymer elastomer (POE) in an internal mixer at 90~110°C for 4-5 minutes according to weight percentage, a...

Embodiment 2

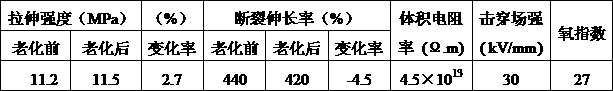

[0058] Example 2. A high-strength and high-elongation flame-retardant rubber insulating cable material. The composition of the material is: chlorinated polyethylene (CPE) 12 kg, ethylene-octene copolymer elastomer (POE) 19 kg, 800 #7 kg of paraffin-based rubber oil, 0.8 kg of activated magnesium oxide, 1.5 kg of zinc oxide, 7 kg of superfine talcum powder, 0.5 kg of environmental stabilizer, 1.5 kg of microcrystalline wax, 0.8 kg of titanium dioxide, and 3 kg of fumed white carbon black , 17 kg of calcined clay, 19 kg of aluminum hydroxide, 0.6 kg of 4,4′ bis(α,α dimethylbenzyl) diphenylamine, 1.5 kg of dicumyl peroxide, and 1.2 kg of triallyl cyanurate Kilogram.

[0059] The mass fraction of the octene monomer in the above-mentioned ethylene-octene copolymer elastomer is 22%-24%.

[0060] The preparation method is the same as in Example 1.

[0061] The performance testing data of the high-strength and high-elongation flame-retardant rubber insulating cable material prepared...

Embodiment 3

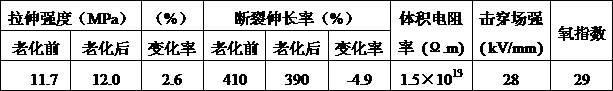

[0064] Example 3. A high-strength and high-elongation flame-retardant rubber insulating cable material, the composition of each component of the material is: chlorinated polyethylene (CPE) 14 kg, ethylene-octene copolymer elastomer (POE) 18 kg, 800 #5 kg of paraffin-based rubber oil, 0.8 kg of activated magnesium oxide, 1.0 kg of zinc oxide, 5 kg of superfine talcum powder, 0.5 kg of environmental stabilizer, 2 kg of microcrystalline wax, 0.8 kg of titanium dioxide, and 5 kg of fumed white carbon black , 17 kg of calcined clay, 19 kg of aluminum hydroxide, 0.6 kg of 4,4′ bis(α,α dimethylbenzyl) diphenylamine, 1.5 kg of dicumyl peroxide, and 1.2 kg of triallyl cyanurate Kilogram.

[0065] The mass fraction of the octene monomer in the above-mentioned ethylene-octene copolymer elastomer is 25%-26%.

[0066] The high-strength and high-elongation flame-retardant rubber insulating cable material prepared by this example has the detection data of performance as follows:

[0067] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com