High-strength high-elongation flame-retardant rubber insulated cable material and processing equipment and process thereof

A flame-retardant rubber and insulated cable technology, applied in the field of cables, can solve the problems of low elongation at break, narrow process range, unqualified elongation at break, etc., achieve good flame retardant performance, improve reinforcement effect and protection effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation process of high-strength and high-elongation flame-retardant rubber insulating cable material, comprising calcium lactobionate 2.2-2.8, ethylene-vinyl acetate copolymer 93-99, SG-1 polyvinyl chloride resin 4.5-5.9, and zinc pyrithione 1.2-1.9, polyvinyl acid 0.1-0.4, azobisisobutyronitrile 1-2, hydrogenated castor oil 1-2, quasi-spherical silica powder 4-5, charcoal powder 2-3, graphite powder 12-13, precipitated sulfuric acid Barium 11-13, 1,4-cyclohexanedimethanol 1-2, thiocyanate 0.3-1, ditetradecyl ester 2-4, composite filler 11-12.5;

[0044] The composite filler is composed of the following raw materials by weight:

[0045] Montmorillonite Powder 21-29, Metallocene Linear Low Density Polyethylene 11-15, Yttrium Oxide 2.1-2.8, Tripropylene Glycol Diacrylate 2-3, Sodium Borohydride 1-2, Methylisothiazolinone 1- 2. Flue ash 2-3;

[0046] Mixing flue ash and tripropylene glycol diacrylate, stirring and mixing at 51-59°C for 2-4 minutes, cooling to room t...

Embodiment 2

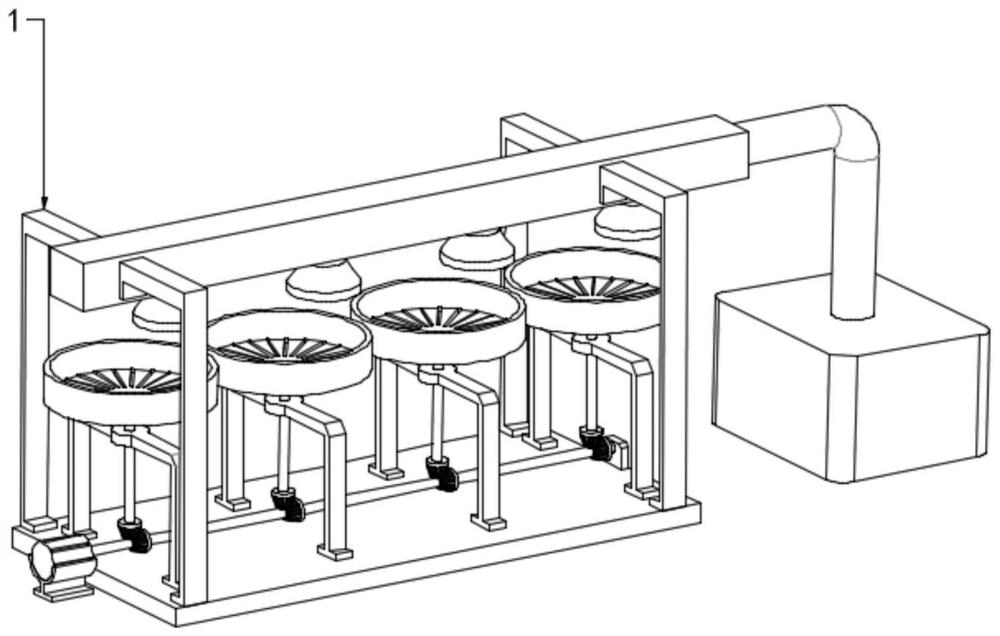

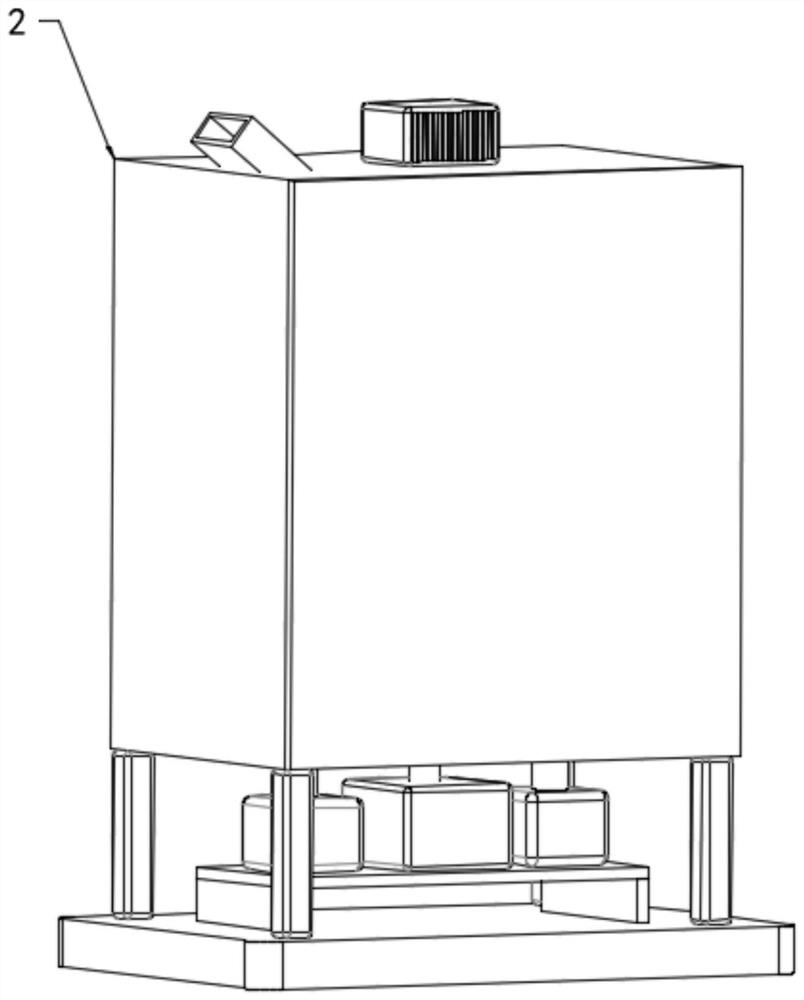

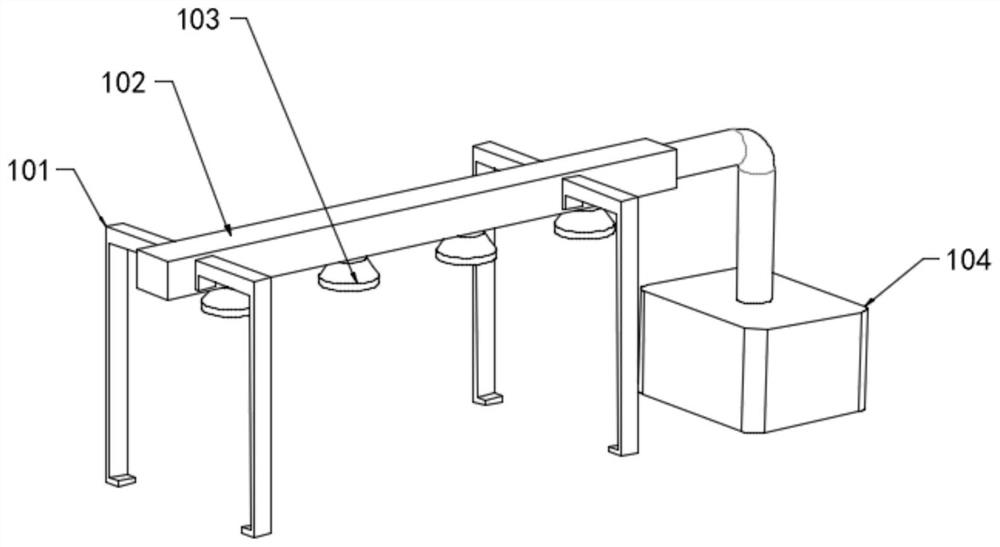

[0062] refer to Figure 1-7 , a processing equipment for high-strength and high-elongation flame-retardant rubber insulated cable material, including: a drainage mechanism 1 and a drying mechanism 2, the drainage mechanism 1 includes a bracket 101, an air supply pipe 102, a blower hood 103, a fan 104, and a base 105 , motor one 106, bottom plate one 107, mounting plate 108, through slot 109, placing frame 110, support seat 111, transmission rod 112, bevel gear one 113, bevel gear two 114, shaft one 115, drying mechanism 2 includes a bottom plate Two 201, drying barrel 202, drying bin 203, feeding pipe 204, drying equipment 205, baffle 206, stirring rod one 207, shaft two 208, mounting seat 209, motor two 210, shaft three 211, stirring rod two 212, the vertical rod 213, the motor three 214, the air cylinder 215, through the cooperation of the drainage mechanism 1 and the drying mechanism 2, the cable material can be quickly dried, and the processing efficiency can be improved. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com