High-strength corrosion-resistant cable for coal mine

A corrosion-resistant, high-strength technology, applied in the field of cable rubber, to achieve good economic benefits, improve tear resistance, and good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

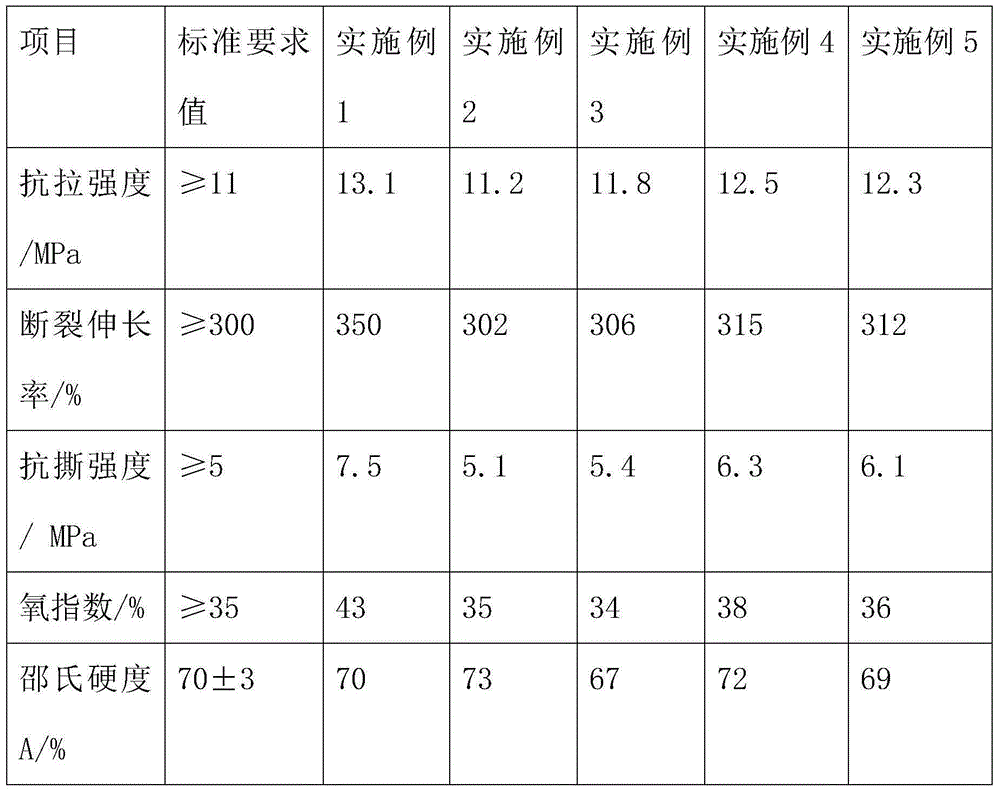

Examples

preparation example Construction

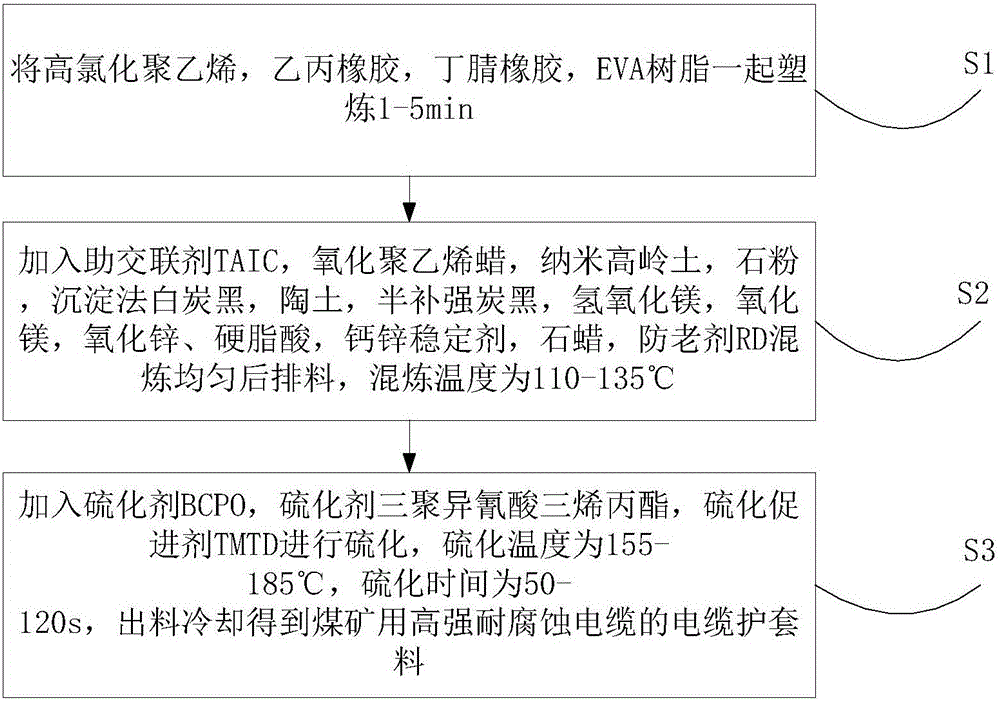

[0027] refer to figure 1 , a kind of preparation method of the cable sheath material of the high-strength corrosion-resistant cable that the present invention proposes, comprises the steps:

[0028] S1. Plasticize high-chlorinated polyethylene, ethylene-propylene rubber, nitrile rubber, and EVA resin together for 1-5 minutes;

[0029] S2. Add cross-linking aid TAIC, oxidized polyethylene wax, nano-kaolin, stone powder, precipitated silica, clay, semi-reinforcing carbon black, magnesium hydroxide, magnesium oxide, zinc oxide, stearic acid, calcium-zinc stabilizer Agent, paraffin, anti-aging agent RD mixed evenly and then discharged, the mixing temperature is 110-135 ℃;

[0030] S3. Add vulcanizing agent BCPO, vulcanizing agent triallyl isocyanate, and vulcanizing accelerator TMTD for vulcanization. The vulcanization temperature is 155-185°C, the vulcanization time is 50-120s, and the material is cooled to obtain high-strength corrosion resistance for coal mines. Cable sheathi...

Embodiment 1

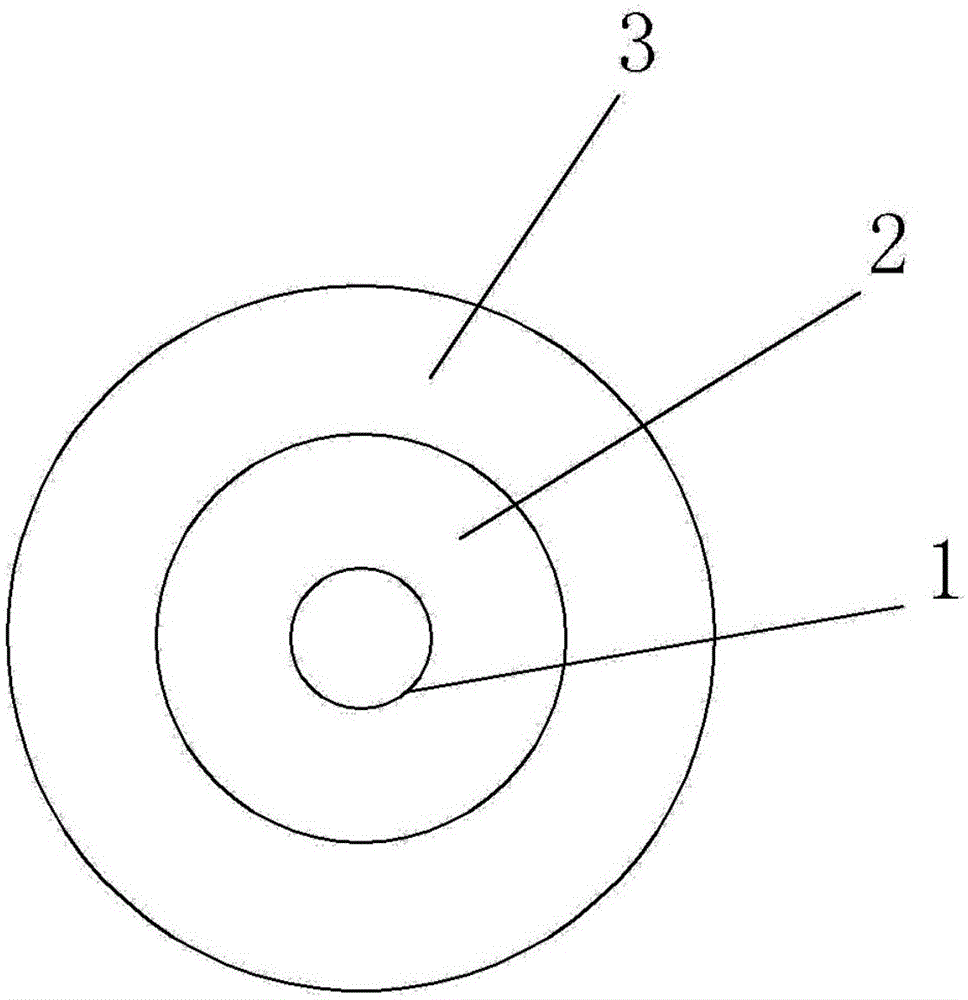

[0033] Such as figure 1 As shown, a kind of high-strength corrosion-resistant cable for coal mine proposed by the present invention comprises a cable core 1, an insulating layer 2 and a sheath layer 3, the outer periphery of the cable core 1 is covered with an insulating layer 2, and the outer periphery of the insulating layer 2 is covered with The sheath layer 3, the raw materials of the sheath layer 3 include by weight: 65 parts of high chlorinated polyethylene, 50 parts of ethylene propylene rubber, 35 parts of nitrile rubber, 35 parts of EVA resin, 2.0 parts of vulcanizing agent BCPO, vulcanizing agent 1.5 parts of triallyl isocyanate, 0.5 parts of vulcanization accelerator TMTD, 1.0 parts of crosslinking agent TAIC, 4 parts of oxidized polyethylene wax, 18 parts of nano kaolin, 10 parts of stone powder, precipitated white carbon black 5 parts, clay 6 parts, semi-reinforcing carbon black 12 parts, magnesium hydroxide 25 parts, magnesium oxide 4.0 parts, zinc oxide 3.5 part...

Embodiment 2

[0039] Such as figure 1 As shown, a kind of high-strength corrosion-resistant cable for coal mine proposed by the present invention comprises a cable core 1, an insulating layer 2 and a sheath layer 3, the outer periphery of the cable core 1 is covered with an insulating layer 2, and the outer periphery of the insulating layer 2 is covered with Sheath layer 3, the raw material of sheath layer 3 includes by weight: 50 parts of high chlorinated polyethylene, 60 parts of ethylene propylene rubber, 30 parts of nitrile rubber, 50 parts of EVA resin, 1 part of vulcanizing agent BCPO, vulcanizing agent trimerization 3 parts of triallyl isocyanate, 0.2 parts of vulcanization accelerator TMTD, 1.5 parts of auxiliary crosslinking agent TAIC, 2 parts of oxidized polyethylene wax, 25 parts of nano kaolin, 5 parts of stone powder, 8 parts of precipitated white carbon black , 3 parts of pottery clay, 15 parts of semi-reinforcing carbon black, 20 parts of magnesium hydroxide, 5 parts of magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com