Water-resistant paint for hull deck and preparation method thereof

A deck and coating technology, applied in the field of water-resistant coatings for hull decks and its preparation, can solve problems such as deficiencies, aging performance, etc., and achieve excellent water resistance and deck protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

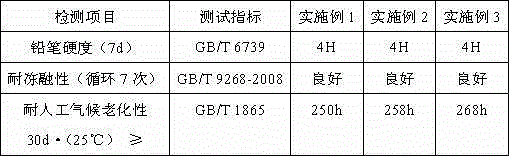

Examples

Embodiment 1

[0010] The present embodiment provides a kind of water-resistant paint for hull deck, which contains the following components in parts by mass: 15 parts of zinc acrylic resin, 15 parts of phenolic resin, 4 parts of polytetrafluoroethylene powder, 3 parts of diisooctyl phthalate, Iron oxide red 13 parts, talc powder 5 parts, barium sulfate 4 parts, chlorinated paraffin 0.08 part, methyl pyrrolidone 0.1 part, molybdenum disulfide 3 parts, manganese naphthenate 0.2 part, coal tar 2 parts.

[0011] The preparation steps of a water-resistant coating for hull deck are as follows: mix iron oxide red, talcum powder, and barium sulfate uniformly, then grind to a fineness≤120 μm; , Methylpyrrolidone, and manganese naphthenate, mixed evenly; then mixed evenly with zinc acrylate resin, polytetrafluoroethylene powder, and coal tar; finally, molybdenum disulfide was added, and mixed evenly to obtain the finished product.

Embodiment 2

[0013] The present embodiment provides a kind of water-resistant paint for hull deck, which contains the following components in parts by mass: 18 parts of zinc acrylic resin, 20 parts of phenolic resin, 5 parts of polytetrafluoroethylene powder, 4 parts of diisooctyl phthalate, Iron oxide red 17 parts, talcum powder 7 parts, barium sulfate 7 parts, chlorinated paraffin 0.1 part, methyl pyrrolidone 0.15 part, molybdenum disulfide 4 parts, manganese naphthenate 0.25 part, coal tar 3.5 parts.

[0014] The preparation steps of a water-resistant coating for hull deck are as follows: mix iron oxide red, talcum powder, and barium sulfate uniformly, then grind to a fineness≤120 μm; , Methylpyrrolidone, and manganese naphthenate, mixed evenly; then mixed evenly with zinc acrylate resin, polytetrafluoroethylene powder, and coal tar; finally, molybdenum disulfide was added, and mixed evenly to obtain the finished product.

Embodiment 3

[0016] The present embodiment provides a kind of water-resistant paint for hull deck, which contains the following components in parts by mass: 24 parts of zinc acrylic resin, 25 parts of phenolic resin, 7 parts of polytetrafluoroethylene powder, 6 parts of diisooctyl phthalate, 22 parts of red iron oxide, 10 parts of talc, 10 parts of barium sulfate, 0.13 parts of chlorinated paraffin, 0.25 parts of methyl pyrrolidone, 5 parts of molybdenum disulfide, 0.37 parts of manganese naphthenate, 4.2 parts of coal tar.

[0017] The preparation steps of a water-resistant coating for hull deck are as follows: mix iron oxide red, talcum powder, and barium sulfate uniformly, then grind to a fineness≤120 μm; , Methylpyrrolidone, and manganese naphthenate, mixed evenly; then mixed evenly with zinc acrylate resin, polytetrafluoroethylene powder, and coal tar; finally, molybdenum disulfide was added, and mixed evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com