Silicone rubber composition, silicone rubber and preparation method therefor

A technology of silicone rubber composition and silicone rubber, which is applied in the field of silicone rubber, can solve the problems of poor controllability, long operation time, and increased curing time of silicone rubber composition, and achieve the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Specifically, the preparation method of the inhibitor comprises the following steps:

[0030] (1) Provide dihydroxyalkyl polysiloxane;

[0031] (2) Mix the dihydroxyalkyl polysiloxane with raw material A or raw material B, and react to obtain an inhibitor; wherein, the raw material A includes one of maleic acid chloride and fumaryl chloride, and the The raw material B includes one of maleic anhydride, maleic acid and fumaric acid.

[0032] In step (2), when the dihydroxyalkyl polysiloxane is mixed with the raw material A, the molar ratio of the dihydroxyalkyl polysiloxane to the raw material A is 0.9:1 to 2: 1.

[0033] Since the dihydroxyalkyl polysiloxane reacts with the raw material A to generate hydrochloric acid, during the reaction process between the dihydroxyalkyl polysiloxane and the raw material A, triethylamine, pyridine, Acid-binding agents such as sodium hydroxide. The acid-binding agent can react with hydrochloric acid to improve the reaction efficienc...

Embodiment 1

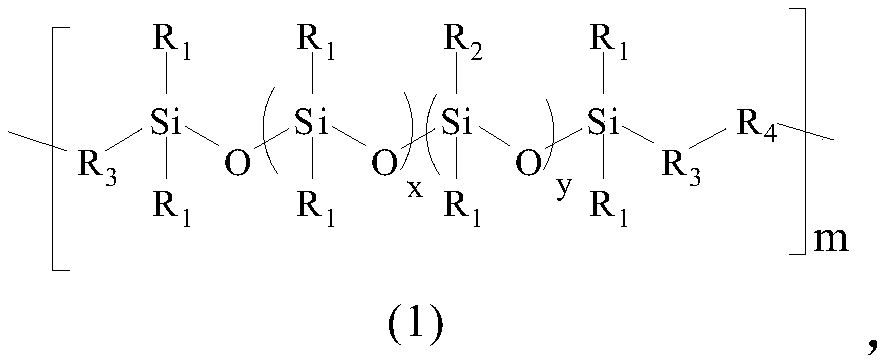

[0078] Dissolve 100g (73.5mmol) dihydroxyethyl polydimethylsiloxane (hydroxyl silicone oil, hydroxyl content 2.5wt%, viscosity 50cp~120cp) in 500mL toluene, add 11g pyridine and stir, place in a 2L three-mouth glass Into the flask, 11.3g (73.5mmol) of fumaryl chloride was slowly added dropwise, and the dropwise addition was completed in 30 minutes, then the temperature was slowly raised to 50°C, and stirred overnight. The precipitate was removed by filtration. The filtrate was washed three times with 200 mL and 5% aqueous sodium carbonate solution, three times with 200 mL water, and three times with 200 mL saturated NaCl solution, dried by adding anhydrous magnesium sulfate, filtered, and distilled to remove the solvent to obtain the inhibitor. The inhibitor is a fumaric acid ester with polysiloxane long-chain structure, the viscosity is 5000cp, and the structural formula is as follows:

[0079]

[0080] 100 parts by weight of vinyl-containing polysiloxane with a viscosity...

Embodiment 2

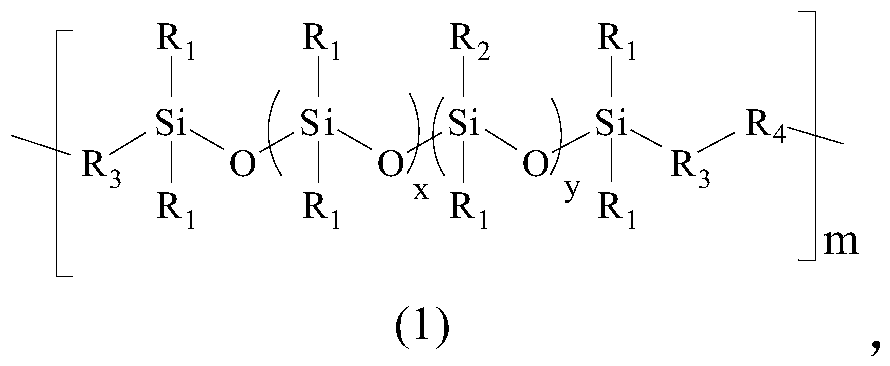

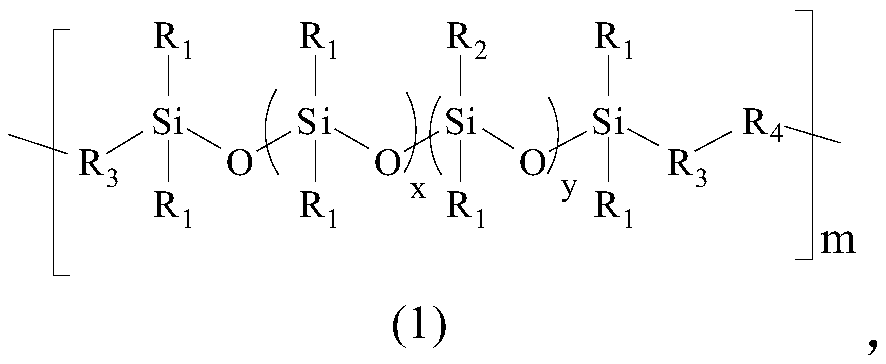

[0083] Dissolve 100g (14.7mmol) dimethylolpolymethylethylsiloxane (hydroxyl silicone oil, hydroxyl content 0.5wt%) in 500mL toluene, add 1.44g (14.7mmol) maleic anhydride, 0.5mg p-toluene Sulfonic acid is used as a catalyst, placed in a 2L three-necked glass flask, heated to reflux of toluene, and the water generated by the reaction is removed through a water separator, and refluxed until no more water is generated. Wash with 200mL, 5% sodium carbonate aqueous solution three times, 200mL water three times, 200mL saturated NaCl solution, add anhydrous magnesium sulfate to dry, filter, and distill off the solvent to obtain the inhibitor, which is polysiloxane Maleic acid ester with long chain structure, viscosity 12000cp. The structural formula is as follows:

[0084]

[0085]100 parts by weight of vinyl-containing polysiloxane with a viscosity of 740 Pa·s at 25°C, 20 parts by weight of organohydrogenpolysiloxane with a viscosity of 0.5mPa·s at 25°C, 0.12 parts of polysiloxa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com