Method for preparing fluorine-containing rubber for automobile rubber pipe

A technology of fluorine-containing rubber and automotive rubber hose, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of poor oil resistance and solvent resistance, improve oil resistance and acid and alkali resistance, and improve vulcanization speed and fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

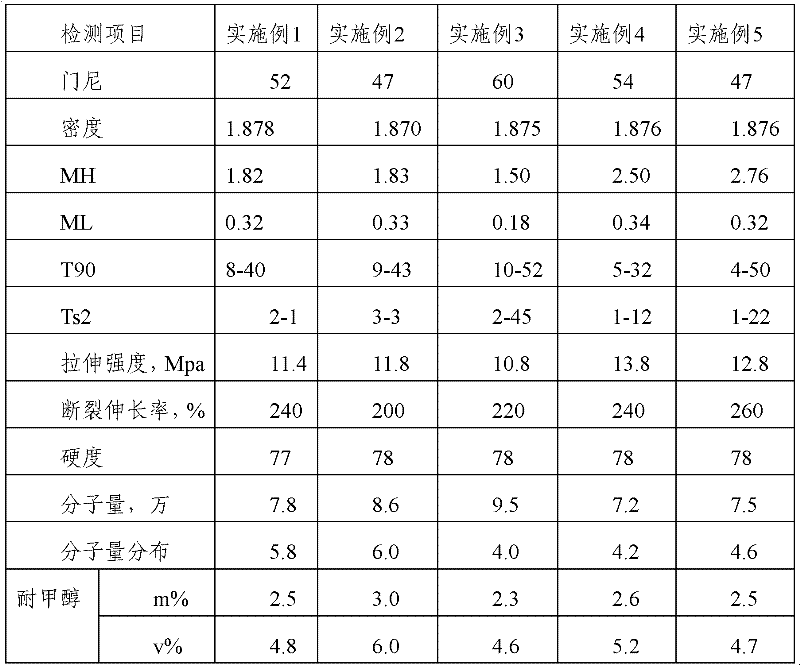

Examples

Embodiment 1

[0027] 50L vertical reactor, add 30L deionized water, evacuate until the oxygen content is less than 50ppm, add 20g of perfluoroisopropyl ether peroxide, add the initial monomer reactor pressure to 2.0MPa, the tetrafluoroethylene in the initial mixed monomer Ethylene: vinylidene fluoride: the molar ratio of perfluoropropylene is 5: 50: 45, and be warming up to 85 ℃ simultaneously, add the ammonium persulfate solution, 30g borax, 15g diethyl malonate that 6g mass fraction is 0.1%, Start the reaction, during which additional mixed monomers are added to maintain the pressure of the reactor at 2.0Mpa. The molar ratio of tetrafluoroethylene: vinylidene fluoride: perfluoropropylene in the added mixed monomers is 10:68:22. Turn on the continuous feed pump at this time, continuously feed tetrafluorodibromoethane at a rate of 2.5 g / min, stop the feed after about 60 min, and stop the reaction when the feed reaches 12 kg. Recover the monomer to the monomer storage tank, evacuate, release...

Embodiment 2

[0029] 50L vertical reaction kettle, add 30L deionized water, evacuate until the oxygen content is less than 50ppm, add 15g perfluoroisopropyl ether peroxide, add the initial monomer reaction kettle pressure is 5.0Mpa, the tetrafluoroethylene in the initial mixed monomer Ethylene: vinylidene fluoride: the molar ratio of perfluoropropylene is 1: 55: 45, and simultaneously heat up to 100 DEG C, add 3g mass fraction and be 1% potassium persulfate solution, 60g borax, 30g ethyl acetate, start reaction, During this period, additional mixed monomers were added to maintain the pressure of the reactor at 5.0Mpa, and the molar ratio of tetrafluoroethylene: vinylidene fluoride: perfluoropropylene in the additional mixed monomers was 15:65:30, and the continuous Add the pump to continuously add perfluorobutyl diiodide at a rate of 2.5g / min, stop the addition after about 12 minutes, and stop the reaction when the feed reaches 12kg. Recover the monomer to the monomer storage tank, evacuate...

Embodiment 3

[0031] 50L vertical reaction kettle, add 30L deionized water, evacuate until the oxygen content is less than 50ppm, add 30g perfluoroisopropyl ether peroxide, add the initial monomer reaction kettle pressure is 4.5Mpa, the tetrafluoroethylene in the initial mixed monomer The molar ratio of ethylene: vinylidene fluoride: perfluoropropylene is 3: 52: 50, and at the same time, the temperature is raised to 60 ° C, and 15 g of ammonium persulfate solution, 45 g of borax, and 6 g of carbon tetrachloride are added to start the reaction. , during which additional mixed monomers are added to maintain the pressure of the reactor at 4.5Mpa, and the molar ratio of tetrafluoroethylene: vinylidene fluoride: perfluoropropylene in the additional mixed monomers is 1:70:20, and it will be opened when the feed reaches 8.5kg Continuously add the pump, add diiodomethane continuously at a rate of 2.5g / min, stop adding after about 24min, and stop the reaction when the feed reaches 12kg. Recover the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com