High-performance rubber for generator shock pad and preparation process thereof

A shock-absorbing pad and high-performance technology, which are applied in the field of high-performance rubber for generator shock-absorbing pads and its preparation process, can solve the problem of low breaking strength and elongation at break, high hardness of shock-proof rubber composition, and enhanced comprehensive performance. limited problems, to achieve the effect of increasing Shore hardness, improving anti-aging properties, and good and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

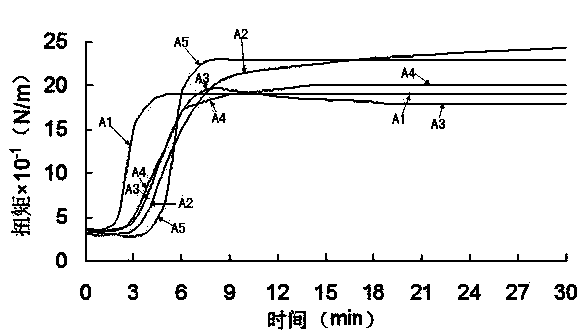

Image

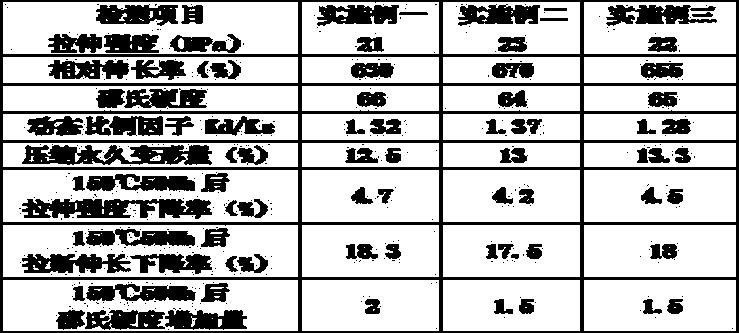

Examples

Embodiment 1

[0029] A preparation process of high-performance rubber for generator shock pads, comprising the steps of:

[0030] ①Premixing: Use an appropriate amount of xylene solution as a solvent, heat it to 80°C, add 0.5 parts of m-phenylenediamine, and after it is completely dissolved, add 0.5 parts of accelerator BMI, stir at 90°C for 5 minutes, and mix xylene Evaporate it, then dry it in an oven at 60°C for 5 minutes, grind it into powder with a pulverizer, and set aside;

[0031] ②Mixing: Add 0.1 part of peptizer DBD to 100 parts of natural rubber, plasticize 5 times on the double-roller open mill, and after wrapping evenly, add 4 parts of 100 mesh zinc oxide and 0.9 parts of Fatty acid, 0.2 parts of anti-scorch agent CTP, and then add 28 parts of spray carbon black for mixing. The mixing temperature of the front roll is 55 ° C, and the mixing temperature of the rear roll is 50 ° C. After the mixing is uniform, the material is discharged;

[0032] ③Vulcanization: Put the film made...

Embodiment 2

[0034] On the basis of the process in Example 1, the following formula and process parameters were changed: in the premixing step, 0.55 parts of m-phenylenediamine and 0.55 parts of accelerator BMI were used, and stirred at 90°C for 6 minutes; in the mixing step, 0.15 parts of Peptizer DBD, 4.5 parts of 100-mesh zinc oxide, 1 part of stearic acid, 0.25 parts of anti-scorch agent CTP, and then add 30 parts of spray carbon black for mixing. The mixing temperature of the front roller is 57 ° C, and the mixing temperature of the rear roller The temperature is 52°C; in the vulcanization step, add 3 parts of vulcanizing agent DCP, and vulcanize under normal pressure at 170°C for 27 minutes to obtain the desired product.

Embodiment 3

[0036] On the basis of the process in Example 1, the following formula and process parameters were changed: in the premixing step, 0.6 parts of m-phenylenediamine and 0.6 parts of accelerator BMI were used, and stirred at 90°C for 7 minutes; in the mixing step, 0.2 parts of Peptizer DBD, 5 parts of 100-mesh zinc oxide, 1.1 parts of stearic acid, 0.3 parts of anti-scorch agent CTP, and then add 32 parts of spray carbon black for mixing. The mixing temperature of the front roller is 60 ° C, and the mixing temperature of the rear roller The temperature is 55°C; in the vulcanization step, add 3.5 parts of vulcanizing agent DCP, and vulcanize under normal pressure at 175°C for 30 minutes to obtain the desired product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com