Manufacturing method for latex labor-protective gloves

A technology for protective gloves and a manufacturing method, which is applied to gloves, protective clothing, clothing and other directions, can solve the problems of wasting manpower, gloves do not absorb sweat, waste resources, etc., and achieve the effects of avoiding waste, strong wear resistance, and reducing defective rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

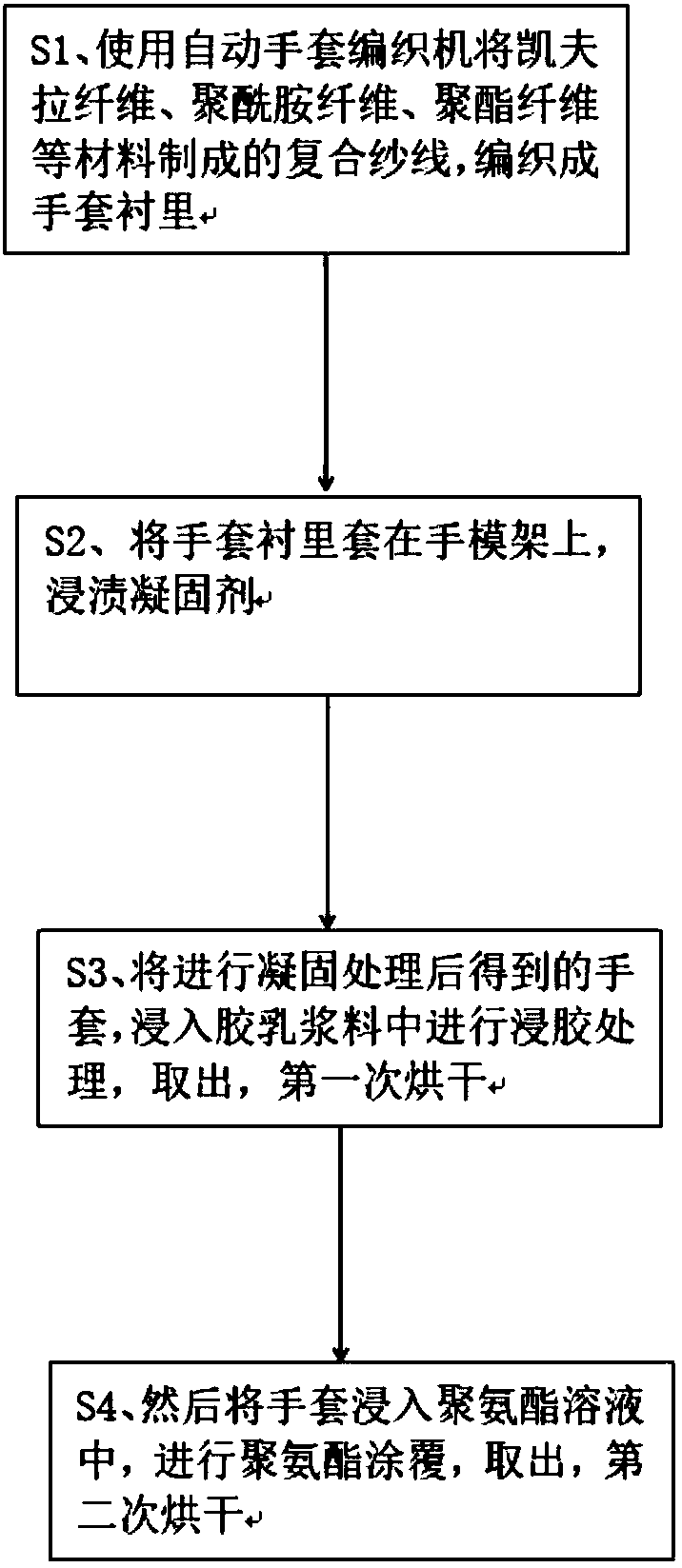

[0044] Present embodiment relates to a kind of manufacture method of latex labor protection gloves, comprises the following steps:

[0045] Step S1, using an automatic glove knitting machine to weave composite yarn made of Kevlar fiber, polyamide fiber, polyester fiber and other materials into a glove lining;

[0046] Step S2, putting the glove liner on the hand mold frame, and impregnating the coagulant;

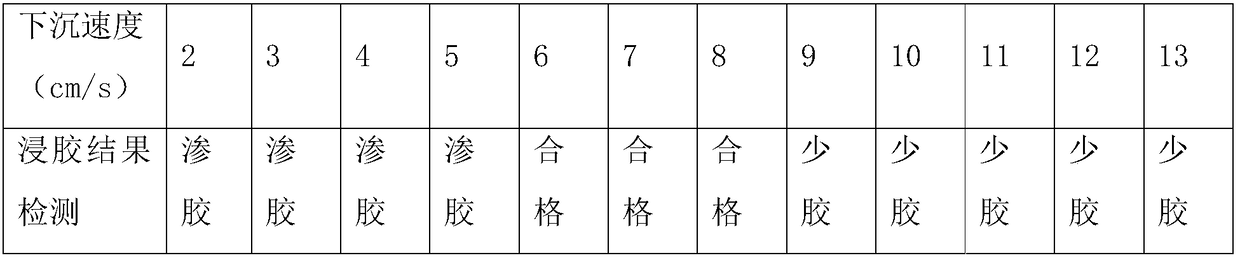

[0047] Step S3, immerse the gloves obtained after the coagulation treatment into the latex slurry for dipping treatment, take them out, and dry them for the first time;

[0048] Step S4, then immerse the glove in the polyurethane solution for polyurethane coating, take it out, and dry it for the second time.

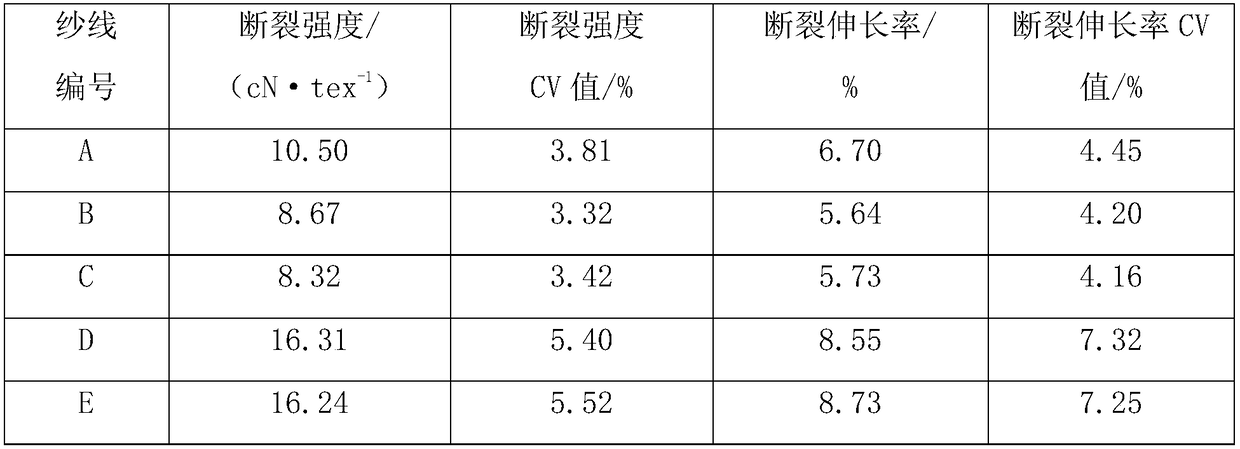

[0049] In this embodiment, the composite yarn is prepared by using Kevlar fiber as the core thread and wrapping the core thread with a plurality of polyamide fibers or polyester fibers. It is preferred to use three polyamide fibers or three polyester fibers.

[005...

Embodiment 2

[0073] Present embodiment relates to a kind of manufacture method of latex labor protection gloves, comprises the following steps:

[0074] Step S1, taking the Kevlar fiber as the core thread and wrapping the core thread with three polyamide fibers to obtain a composite yarn, and using an automatic glove knitting machine to weave the composite yarn into a glove lining;

[0075] Step S2, put the glove liner on the hand mold frame, impregnate the coagulant,

[0076] Step S3, immerse the gloves obtained after the coagulation treatment into the latex slurry for dipping treatment, take them out, and dry them for the first time;

[0077] Step S4, then immerse the glove in the polyurethane solution for polyurethane coating, take it out, and dry it for the second time.

[0078] The preparation of coagulant in the present embodiment comprises the steps:

[0079] Get calcium nitrate and calcium chloride to mix, add in the methanol solution;

[0080] Adding 0.1-0.2 parts by weight of ...

Embodiment 3

[0110] Present embodiment relates to a kind of manufacture method of latex labor protection gloves, comprises the following steps:

[0111] Step S1, taking the Kevlar fiber as the core thread and wrapping the core thread with three polyamide fibers to obtain a composite yarn, and using an automatic glove knitting machine to weave the composite yarn into a glove lining;

[0112] Step S2, put the glove liner on the hand mold frame, impregnate the coagulant,

[0113] Step S3, immerse the gloves obtained after the coagulation treatment into the latex slurry for dipping treatment, take them out, and dry them for the first time;

[0114] Step S4, then immerse the glove in the polyurethane solution for polyurethane coating, take it out, and dry it for the second time.

[0115] In the present embodiment, the solid content of each component of the polyurethane solution is as follows

[0116] Aliphatic polyurethane 20%-40%,

[0117] Alkylphenol ethoxylates 0.5%-5%,

[0118] Silicone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com