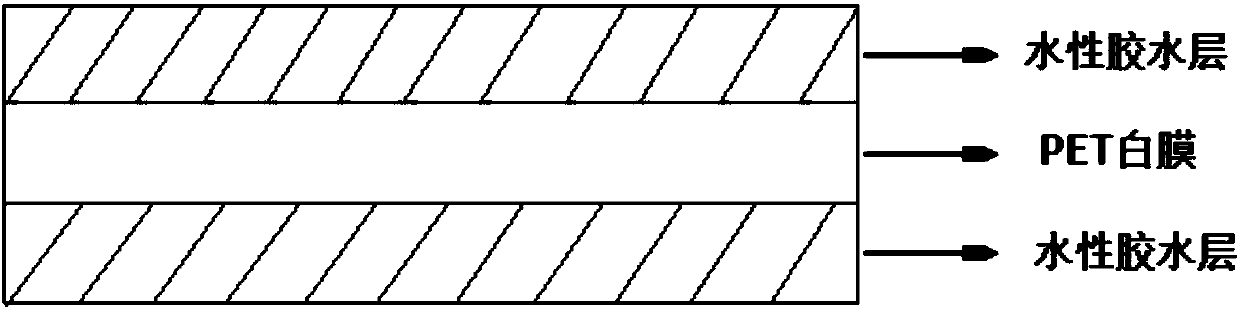

PET card film and preparation method thereof

A card film, white film technology, applied in the direction of film/sheet adhesive, adhesive type, polyurea/polyurethane adhesive, etc. Water resistance, poor high temperature and high humidity resistance, etc., to achieve the effect of stable adhesion, improved adhesion resistance, and good high temperature and high humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

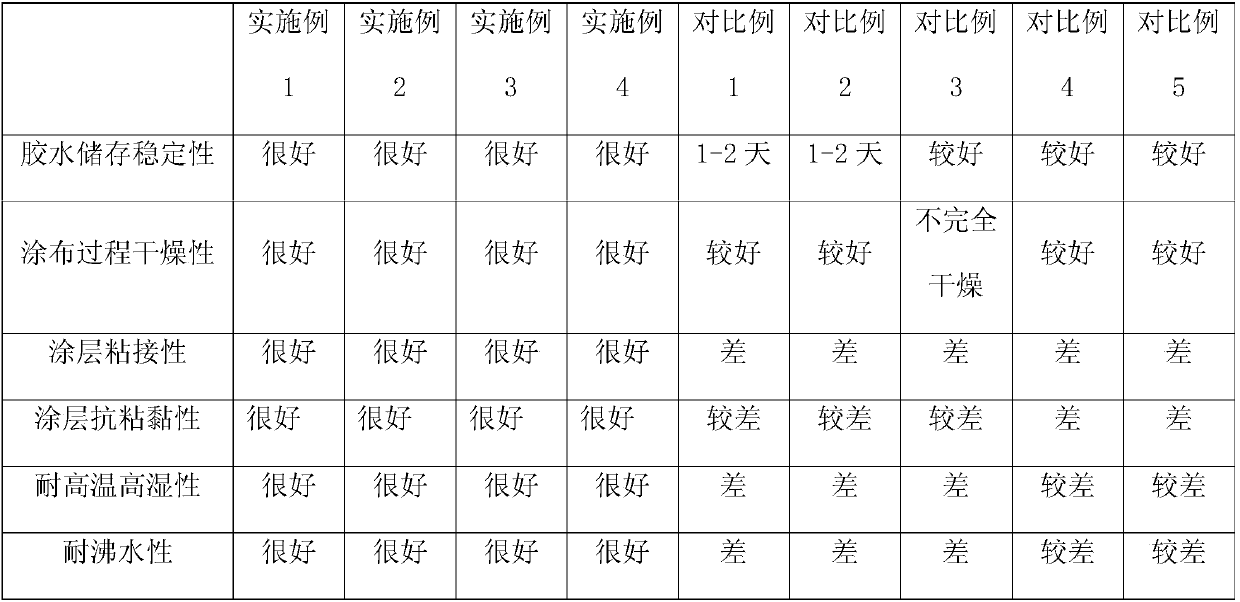

Embodiment 1

[0025] The raw materials are: aliphatic water-based polyurethane resin: 60 parts, BYK-192 water-based dispersant: 3 parts, deionized water: 25 parts, Degussa matting powder TS100: 5 parts, water-based polytetrafluoroethylene wax powder : 1 part, TEGO WetKL245 water-based substrate wetting agent: 0.2 parts, BYK-021 water-based defoamer: 0.3 parts, BYK-333 water-based leveling agent: 0.4 parts, DMEA 0.1 part , Water-based blocked isocyanate curing agent: 5 parts.

[0026] Add water-based polyurethane resin to the reaction kettle, then add water, dispersant, water-based defoamer, water-based wetting agent, water-based leveling agent, matting powder, water-based PTFE wax powder, blocked isocyanate curing agent, high-speed dispersion , stir evenly, adjust the pH value to 7.5-8 with DMEA, filter to remove impurity particles, and prepare water-based glue for PET card film.

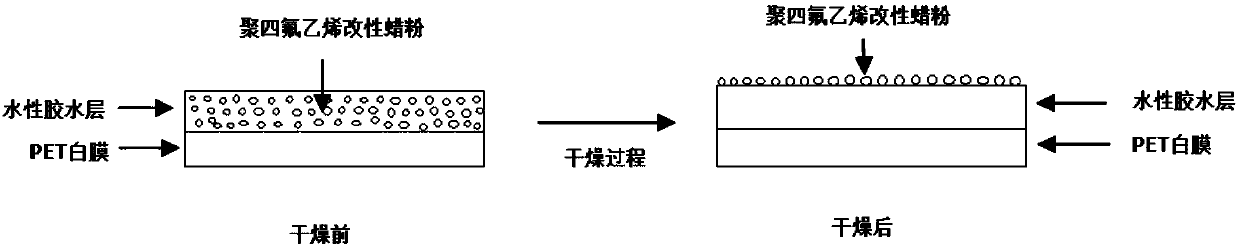

[0027] Double coating on one side, first adjust the coating viscosity to 15-20sec with water-based glue (coat...

Embodiment 2

[0029] The raw materials are: aliphatic water-based polyurethane resin: 53 parts, BYK-192 water-based dispersant: 5 parts, deionized water: 24 parts, Degussa matting powder TS100: 8 parts, water-based polytetrafluoroethylene wax powder : 2 parts, German TEGO Wet280 water-based substrate wetting agent: 0.6 parts, German TEGO 902W water-based defoamer: 0.6 parts, German BYK-333 water-based leveling agent: 0.6 parts, DMEA 0.2 parts, Water-based blocked isocyanate curing agent: 6 parts.

[0030] Preparation method and coating method are the same as embodiment 1

Embodiment 3

[0032] The raw materials are: aliphatic water-based polyurethane resin: 65 parts, BYK-192 water-based dispersant: 2 parts, deionized water: 20 parts, Degussa matting powder TS100: 6 parts, water-based polytetrafluoroethylene wax powder : 1 part, German TEGO Wet280 water-based substrate wetting agent: 0.3 parts, German TEGO 902W water-based defoamer: 0.3 parts, German BYK-333 water-based leveling agent: 0.3 parts, DMEA 0.1 part, Water-based blocked isocyanate curing agent: 5 parts.

[0033] Preparation method and coating method are the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com